Bismuth ferrite/lead titanate based functional ceramic material and preparation method thereof

A bismuth ferrite lead titanate-based, functional ceramic technology, applied in the field of ferrous functional ceramic materials, can solve the problems of inability to obtain saturated hysteresis loops, failure to put into use, and many chemical defects, and achieve improved breakdown field strength The effect of ferroelectric properties, reduced lattice stress, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of bismuth ferrite lead titanate-based functional ceramic material, comprising the following steps:

[0033] Step 1, take required raw material by stoichiometric ratio, each raw material molar ratio is: Fe 2 o 3 :X 2 o 3 :TiO 2 :PbO:Bi 2 o 3 =x:0.1x:(1-x):(1-x):0.9x, 0.6≤x≤0.9, X 2 o 3 It is the rare earth oxide used for modification, and the raw material is fully mixed and ground to a smaller particle size to obtain the raw material;

[0034] Step 2. Pre-press the homogeneously mixed raw material obtained in Step 1 in a mold with a pressure of 100 MPa-500 MPa, and then place it in a high-temperature reaction furnace and heat it up to 700°C-950°C for pre-sintering. Compared with traditional In terms of a heating rate of 5°C / min, the present invention adopts a heating rate as high as 10°C / min-20°C / min, and keeps the temperature for 60min-200min to obtain a pre-sintered sample;

[0035] Step 3. Put the pre-sintered sample obtained in Step 2 i...

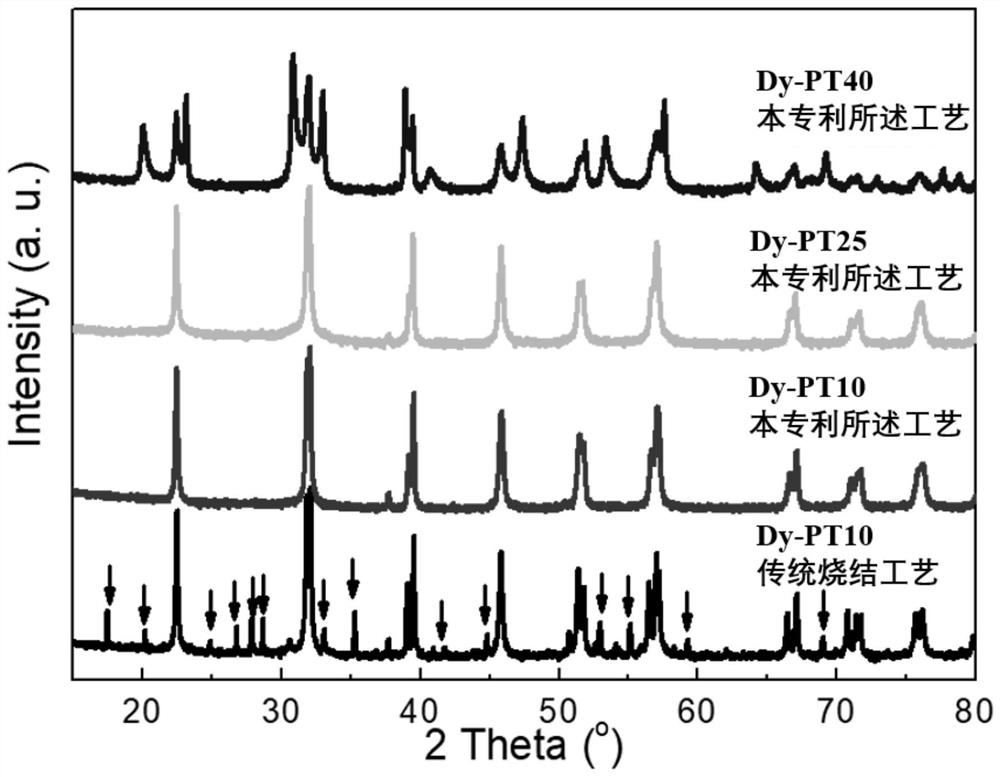

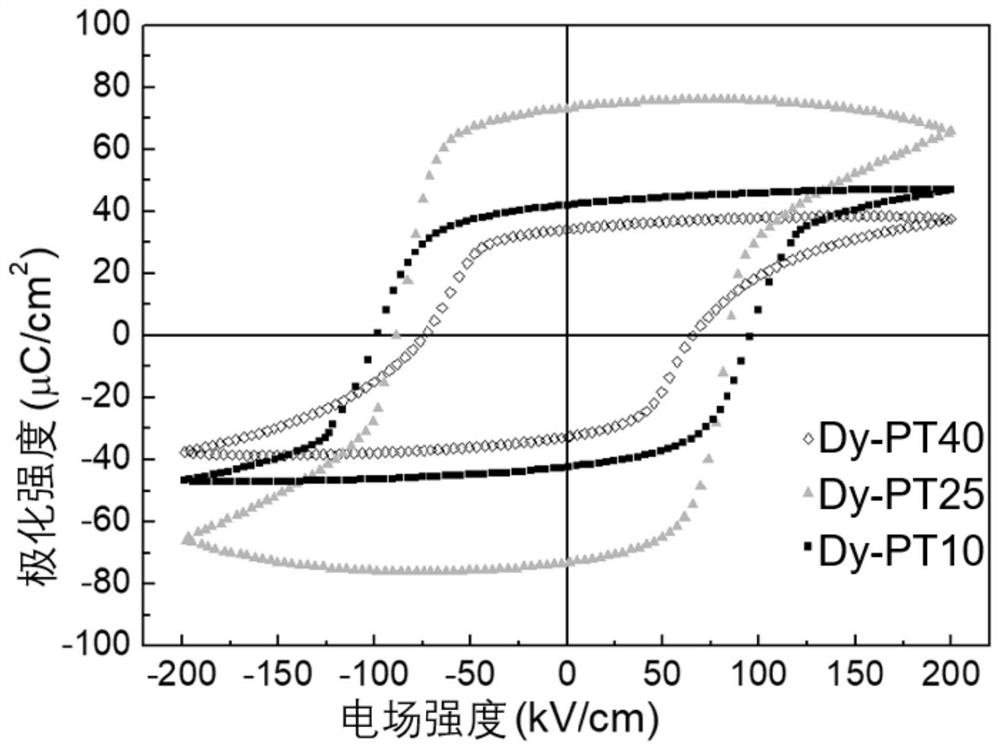

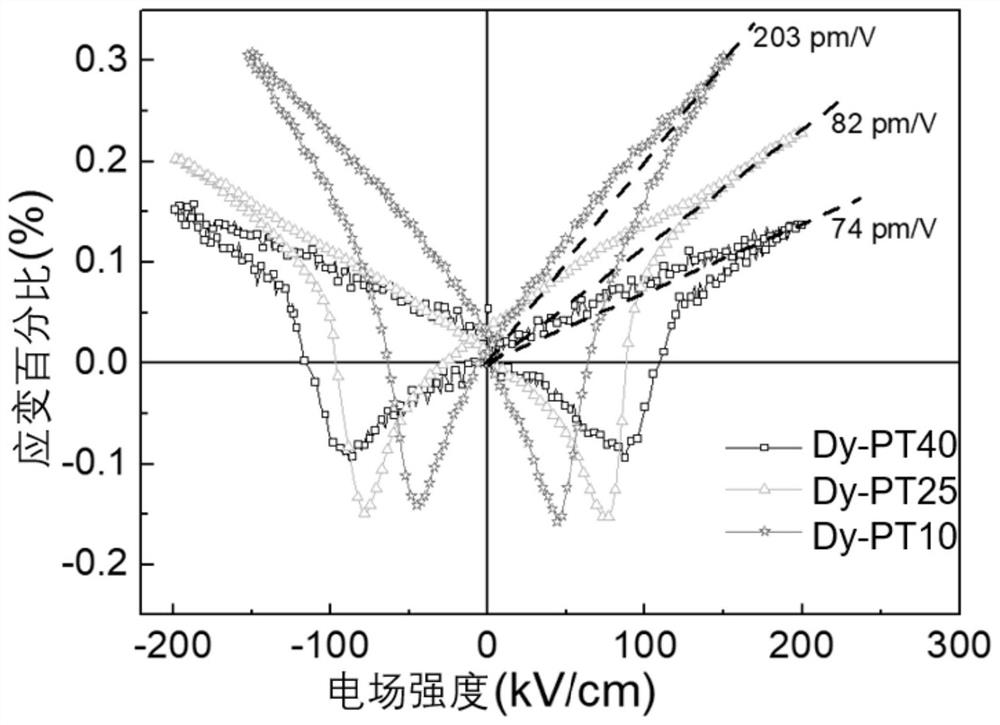

Embodiment 1

[0039] A Dy (dysprosium)-doped 0.9BiFeO prepared by an improved solid-state sintering process 3 -0.1PbTiO 3 Functional ceramic material, the chemical composition is 0.9Bi 0.9 Dy 0.1 FeO 3 -0.1PbTiO 3 , referred to as Dy-PT10. Including the following steps:

[0040] Step 1: Take the required raw materials according to the stoichiometric ratio: the molar ratio of each raw material is: Fe 2 o 3 : Dy 2 o 3 : TiO 2 :PbO:Bi 2 o 3 :=0.9:0.09:0.2:0.2:0.81, fully mix the raw materials and grind them to obtain the raw materials.

[0041] Step 2: The uniformly mixed raw material obtained in step 1 is pre-pressed in a mold with a pressure of 100 MPa, and then placed in a high-temperature reaction furnace to raise the temperature to 700°C and then held for 200 minutes for pre-sintering to obtain a pre-sintered sample. Compared with the traditional process, a higher heating rate is adopted here: 10°C / min;

[0042] Step 3: Put the pre-sintered sample obtained in step 2 into a m...

Embodiment 2

[0046] A Dy-doped 0.75BiFeO prepared by an improved solid-state sintering process 3 -0.25PbTiO 3 Functional ceramic material, the chemical composition is 0.75Bi 0.9 Dy 0.1 FeO 3 -0.25PbTiO 3 , referred to as Dy-PT25. Including the following steps:

[0047] Step 1: Take the required raw materials according to the stoichiometric ratio: the molar ratio of each raw material is: Fe 2 o 3 : Dy 2 o 3 : TiO 2 :PbO:Bi 2 o 3 :=0.75:0.075:0.5:0.5:0.675, fully mix the raw materials evenly and grind to obtain the raw material.

[0048] Step 2: Pre-press the homogeneously mixed raw material obtained in Step 1 in a mold with a pressure of 200 MPa, and then place it in a high-temperature reaction furnace to raise the temperature to 800°C. Compared with the traditional process, a higher heating rate is adopted here. It can reach 12°C / min, keep warm for 100min, and obtain pre-sintered samples.

[0049] Step 3: Put the pre-sintered sample obtained in step 2 into a mortar for second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie temperature | aaaaa | aaaaa |

| Polarization | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com