Super-tough concrete for prefabricated members and preparation method of super-tough concrete

A technology of prefabricated components and super toughness, applied in the field of concrete, can solve the problems of reduced compressive strength, high cost, and reduced elastic modulus, and achieve the effect of improving structural safety and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing super-tough concrete for prefabricated components, comprising the following steps:

[0029] (1) Prepare an aqueous solution of tannic acid with a mass concentration of 1%;

[0030] (2) Weighing Portland cement, aggregate, tannic acid aqueous solution and polycarboxylate high-performance water reducer, the amount of the cement is 300 parts, the amount of the aggregate is 500 parts, where by mass The sand accounts for 30%, the stone accounts for 70%, the consumption of the tannic acid aqueous solution is 100 parts, and the consumption of the polycarboxylate high-performance water reducer is 1 part;

[0031] (3) Add the Portland cement, aggregate, tannic acid aqueous solution and polycarboxylate high-performance water reducing agent into a concrete mixer, and stir for 10 minutes to make concrete;

[0032] (4) The concrete was injection molded, and after curing for 24 hours, the mold was removed for autoclaving curing, the temperature was raised for ...

Embodiment 2

[0035] A method for preparing super-tough concrete for prefabricated components, comprising the following steps:

[0036] (1) Prepare vitamin C aqueous solution with a mass concentration of 1%;

[0037] (2) Weigh ordinary Portland cement, aggregate, vitamin C aqueous solution and polycarboxylate high-performance water reducer, the amount of the cement is 200 parts, the amount of the aggregate is 500 parts, of which The sand accounts for 30%, the stone accounts for 70%, the consumption of the vitamin C aqueous solution is 50 parts, and the consumption of the polycarboxylate high-performance water reducer is 1 part;

[0038] (3) Add the ordinary Portland cement, aggregate, vitamin C aqueous solution and polycarboxylate high-performance water reducing agent into a concrete mixer, and stir for 10 minutes to make concrete;

[0039] (4) Injection mold the concrete, remove the mold after curing for 12 hours, perform steam curing, heat up for 2 hours, keep the temperature at 90°C for...

Embodiment 3~5

[0042] Same as Example 2, the difference lies in: Examples 3-5 adopt standard curing at 20°C, constant temperature water bath curing at 40°C, and autoclaved curing at 180°C, respectively.

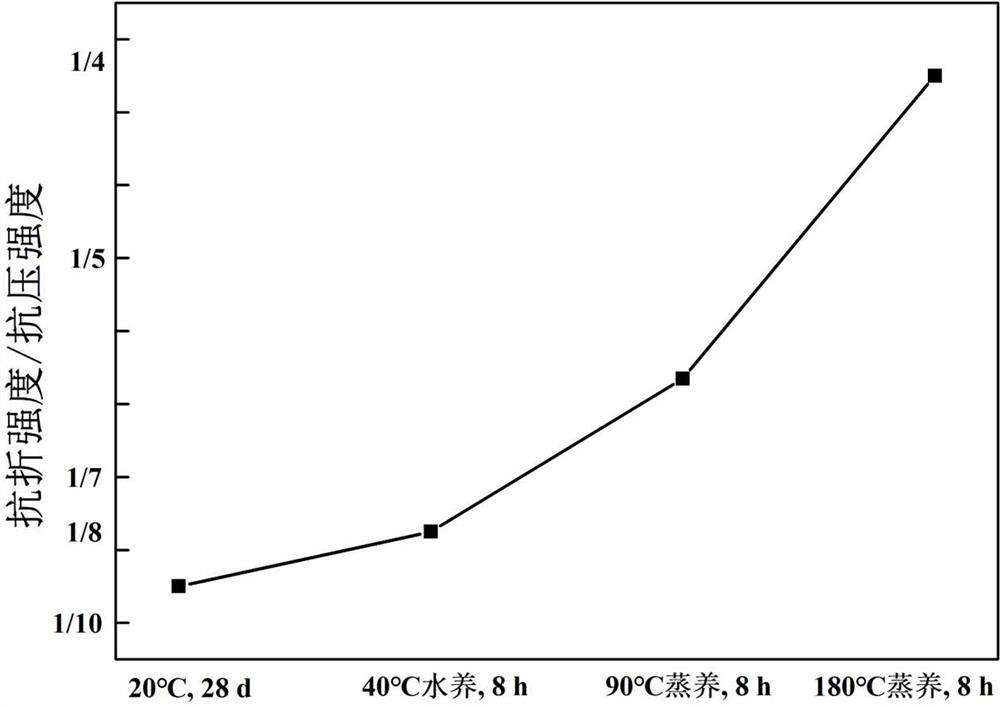

[0043] Measure the flexural compressive strength ratio of the concrete prepared by embodiment 2~5, the result is as follows figure 1 shown. Depend on figure 1 It can be seen that autoclave curing at 180 °C is more conducive to improving the toughening effect of vitamin C concrete precast components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com