Metalloporphyrin@metal organic framework material heterogeneous photosensitizer as well as preparation method and application thereof

A metal-organic framework and metalloporphyrin technology, applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve problems such as strong pollution, harsh conditions, and cumbersome preparation methods , achieving the effects of good repeatability, strong stability, and simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

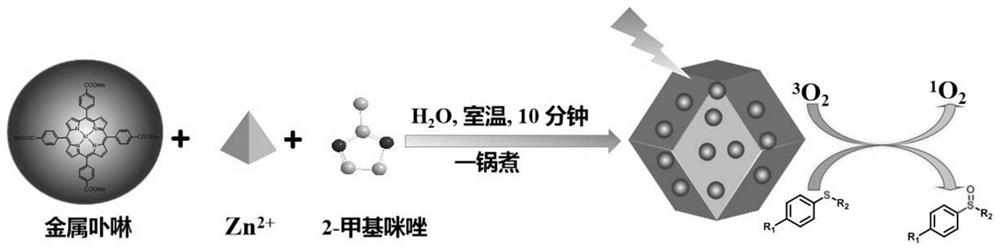

[0035] Example 1. Preparation of zinc porphyrin@ZIF-8

[0036] Zinc porphyrin was prepared according to reference (D.W.Feng, Z.Y.Gu, J.R.Li, et al. Angew. Chem. Int. Ed., 2012, 51, 10307). Then, weigh 20.0 mg of zinc porphyrin and dissolve in 0.5 mL of N,N-dimethylformamide to prepare A solution. Weigh 0.3g Zn(NO 3 )·6H 2 O was dissolved in 1.5 mL distilled water. Weigh 2 g of 2-methylimidazole and dissolve in 4 mL of distilled water. Mix A solution and 2-methylimidazole solution well, then slowly add Zn(NO 3 )·6H 2 O solution, there will be precipitation soon, stir at room temperature for 10-20 minutes to stop the reaction, centrifuge, wash with distilled water, nitrogen nitrogen-dimethylformamide and ethanol several times in sequence until the supernatant becomes colorless, and then Vacuum drying to obtain the final target product zinc porphyrin @ZIF-8, the color is dark green.

Embodiment 2

[0037] Example 2. Preparation of manganese porphyrin@ZIF-8

[0038] Manganese porphyrins were prepared according to reference (D.W.Feng, Z.Y.Gu, J.R.Li, et al. Angew. Chem. Int. Ed., 2012, 51, 10307). Then, weigh 20.0 mg of manganese porphyrin and dissolve in 0.5 mL of N,N-dimethylformamide to prepare A solution. Weigh 0.3g Zn(NO 3 )·6H 2 O was dissolved in 1.5 mL distilled water. Weigh 2 g of 2-methylimidazole and dissolve in 4 mL of distilled water. Mix A solution and 2-methylimidazole solution well, then slowly add Zn(NO 3 )·6H 2 O solution, there will be precipitation soon, stir at room temperature for 10-20 minutes to stop the reaction, centrifuge, wash with distilled water, nitrogen nitrogen-dimethylformamide and ethanol several times in sequence until the supernatant becomes colorless, and then Vacuum drying to obtain the final target product manganese porphyrin @ZIF-8, the product color is light green.

Embodiment 4

[0042] Example 4. Application

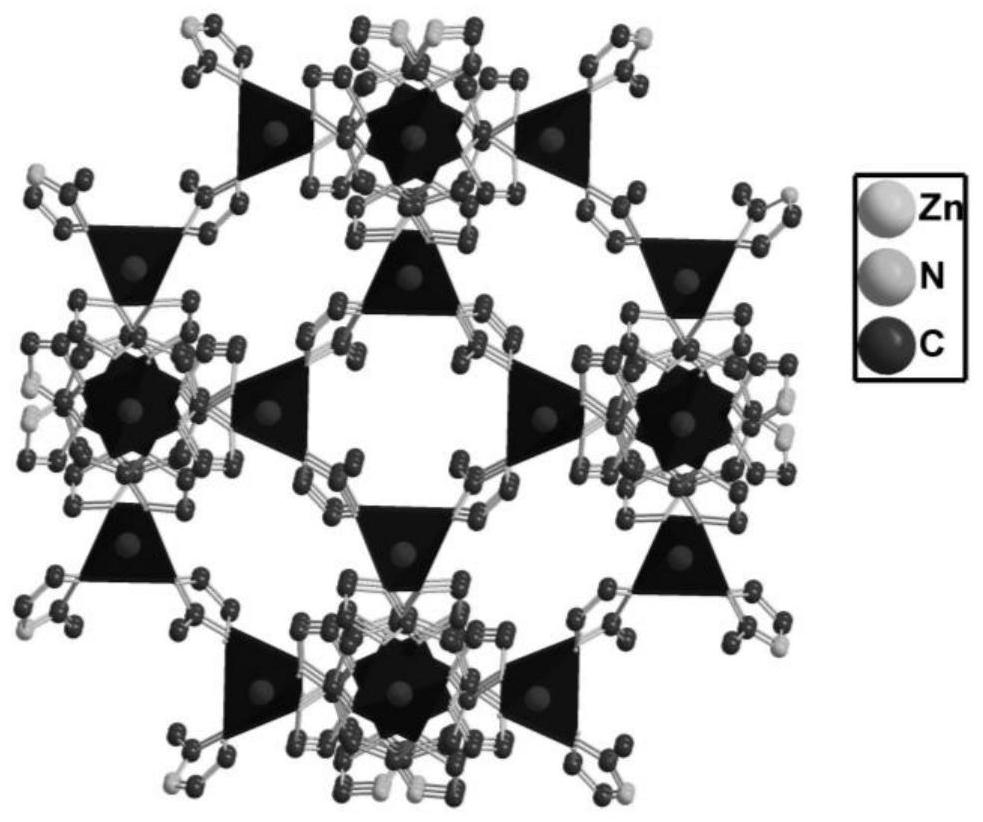

[0043] The crystal structures of ZIF-8, zinc porphyrin @ZIF-8 and manganese porphyrin @ZIF-8 were studied by PXRD, and the results are attached image 3 shown. From attached image 3 It can be seen that the PXRD spectra of ZIF-8, zinc porphyrin@ZIF-8 and manganese porphyrin@ZIF-8 prepared by the present invention are completely consistent with the theoretically simulated ZIF-8, which shows that we have successfully prepared zinc porphyrin Phyrin@ZIF-8 and manganese porphyrin @ZIF-8, and the loading of zinc porphyrin and manganese porphyrin did not destroy the crystal structure integrity of ZIF-8.

[0044] The microscopic morphology and structure of zinc porphyrin @ZIF-8 and manganese porphyrin @ZIF-8 were characterized by scanning electron microscopy (SEM). The results are shown in the attached Figure 4 with 5 shown. It can be seen from the figure that both zinc porphyrin @ZIF-8 and manganese porphyrin @ZIF-8 exhibit a uniform spherical-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com