On-line quenching complex-phase structure hot-rolled wear-resistant steel and preparation method thereof

A wear-resistant steel, controlled rolling technology, applied in the field of hot-rolled wear-resistant steel production, can solve the problems of high alloy content, affecting the weldability of wear-resistant steel plates, and the inaccurate control of ferrite content, etc., to achieve process simplification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

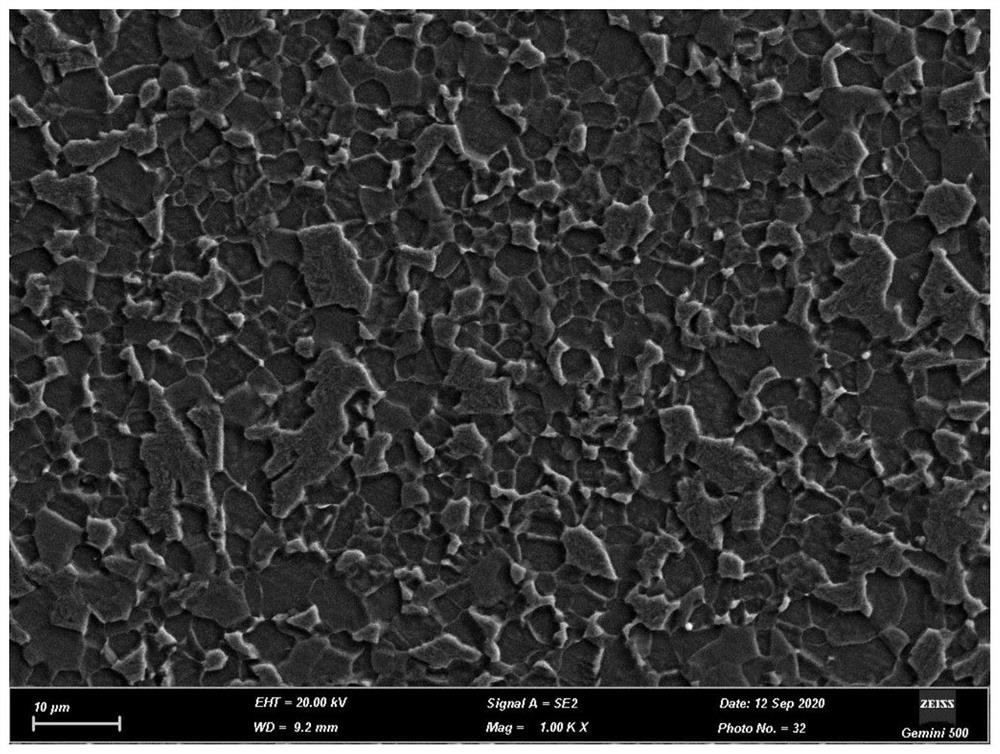

Embodiment 1

[0026] The weight percentage of chemical composition of hot-rolled wear-resistant steel with online quenching multi-phase structure is: C: 0.14%, Mn: 1.5%, Cr: 0.20%, Si: 1.0%, Nb: 0.02%, the balance is Fe and unavoidable impurities;

[0027] Smelting according to the specified chemical composition, including molten iron pretreatment, converter steelmaking, LF external refining, RH degassing treatment, and then adopting slab continuous casting to obtain hot-rolled slabs;

[0028] Heating and homogenizing the slab, the process is to heat the slab to 1200 oC, keep warm for 3 hours, and the temperature of the furnace is 1150 o c. After rough rolling + finishing rolling, it is rolled into a thin plate with a thickness of 4mm. Finish rolling start temperature is 950 o C, the final rolling temperature is 850 o C;

[0029] The hot-rolled plate is subjected to on-line heat treatment, firstly control the cooling speed of the head of the cooling plate to 15 o C / s lasts for 4s, th...

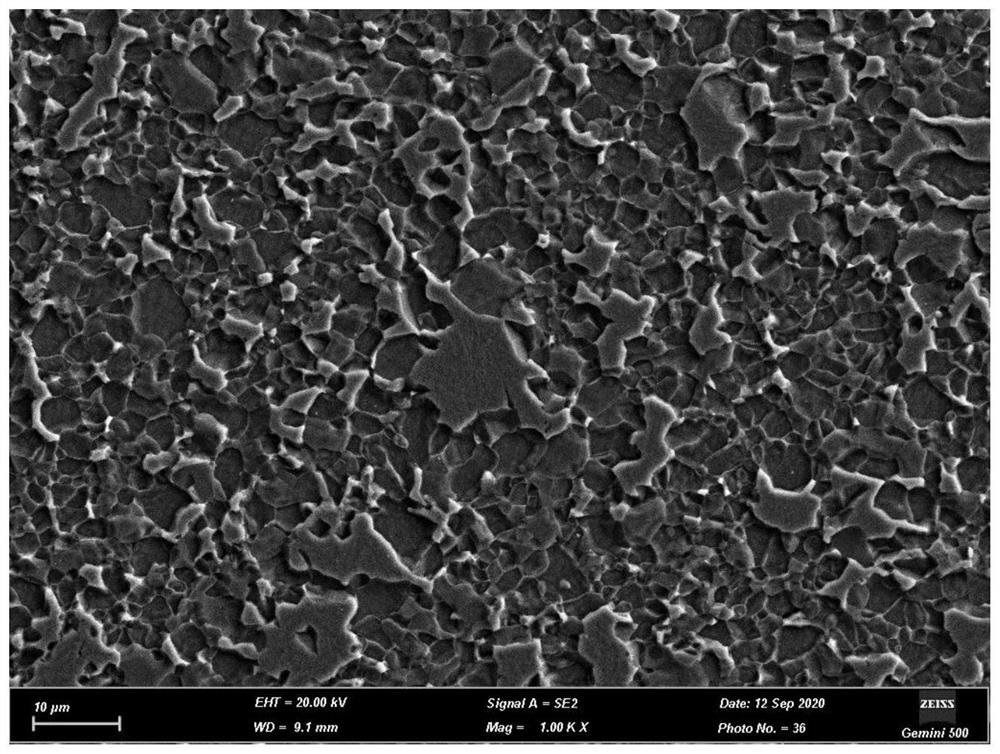

Embodiment 2

[0032] On-line quenching multi-phase structure hot rolling wear-resistant chemical composition weight percentage is: C: 0.14%, Mn: 1.6%, Cr: 0.28%, Si: 1.0%, Nb: 0.02%, the balance is Fe and unavoidable impurities;

[0033] Smelting according to the specified chemical composition, including molten iron pretreatment, converter steelmaking, LF external refining, RH degassing treatment, and then adopting slab continuous casting to obtain hot-rolled slabs;

[0034] Heating and homogenizing the slab, the process is to heat the slab to 1280 o C, keep warm for 4 hours, and the temperature of the furnace is 1200 o c. After rough rolling + finishing rolling, it is rolled into a thin plate with a thickness of 6mm. Finish rolling start temperature is 1050 o C, the finishing temperature is 900 o C;

[0035] The hot-rolled plate is subjected to online heat treatment, firstly control the cooling speed of the head of the cooling plate to 20 o C / s lasts for 5s, then adjust the cooling s...

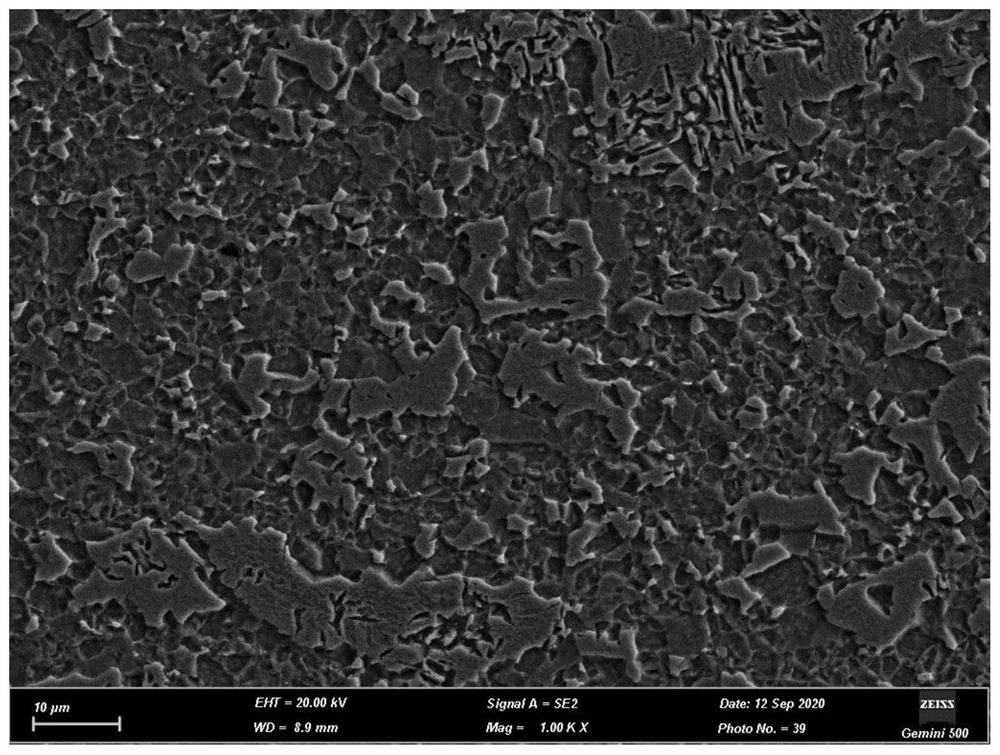

Embodiment 3

[0038] On-line quenching multi-phase structure hot rolling wear-resistant chemical composition weight percentage is: C: 0.18%, Mn: 2.0%, Cr: 0.30%, Si: 1.3%, Nb: 0.04%, the balance is Fe and unavoidable impurities;

[0039] Smelting according to the specified chemical composition, including molten iron pretreatment, converter steelmaking, LF external refining, RH degassing treatment, and then adopting slab continuous casting to obtain hot-rolled slabs;

[0040] Heating and homogenizing the slab, the process is to heat the slab to 1200 o C, keep warm for 4 hours, and the temperature of the furnace is 1160 o c. After rough rolling + finishing rolling, it is rolled into a thin plate with a thickness of 4mm, and the starting temperature of the finishing rolling is 1000 o C, the final rolling temperature is 890 o c.

[0041] The hot-rolled plate is subjected to online heat treatment, firstly control the cooling speed of the head of the cooling plate to 20 o C / s lasts for 4s, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com