Nano inorganic anti-corrosion, anti-seepage and anti-fouling coating structure for hydraulic concrete

A hydraulic concrete, nano-inorganic technology, applied in the field of hydraulic engineering construction, can solve cracks, frost heave, erosion, cavitation, alkali-aggregate reaction, carbonization, dissolution, erosion, microbial corrosion, affecting work efficiency and water quality Safety, affecting the normal water delivery function of the structure, etc., to solve the problems of difficulty in cleaning, consistent thermal expansion and contraction rate, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

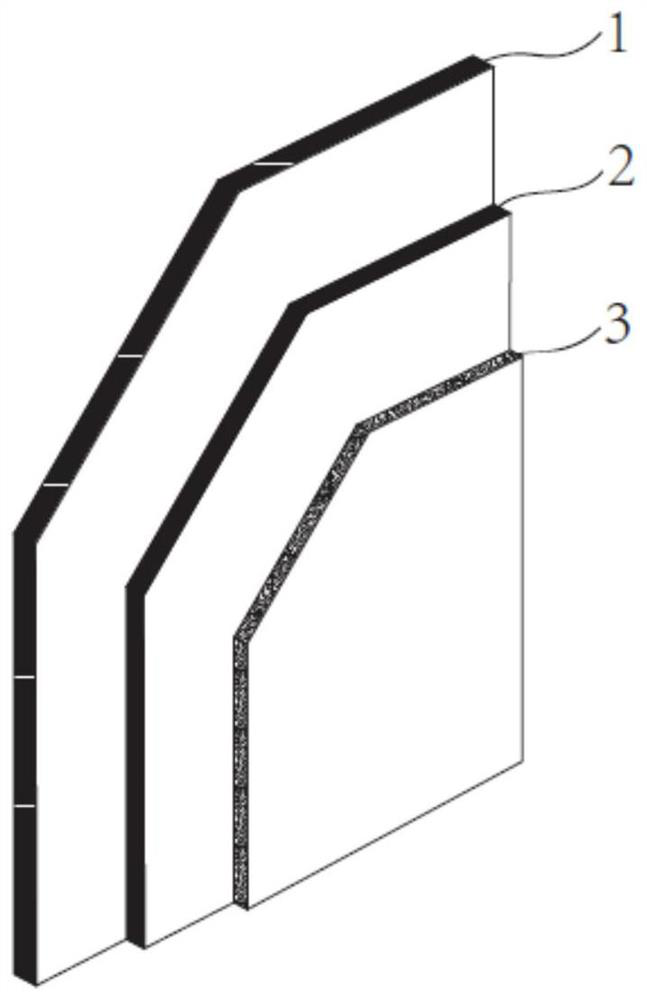

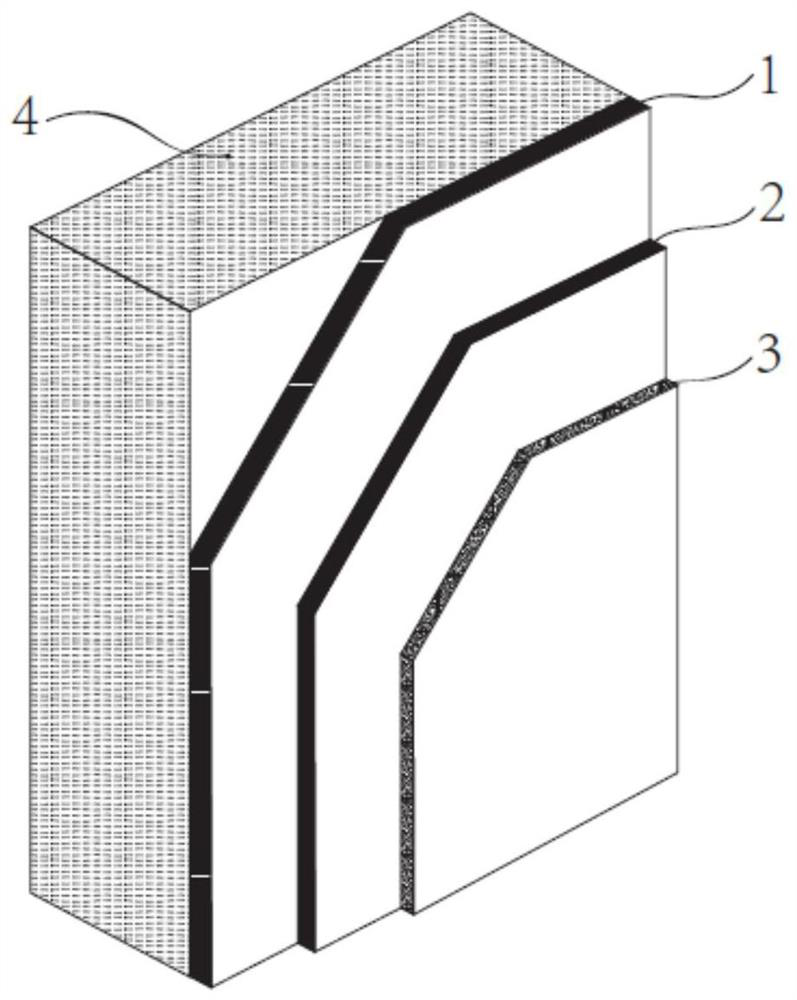

[0053] Two-component polymer mortar bonded primer (1)

[0054] Component A, weighing: 65 kg of styrene-acrylic emulsion, 25 kg of deionized water, 2 kg of dispersant, 1 kg of antibacterial agent, 2 kg of defoamer; mix and stir the weighed materials to obtain component A for use ;

[0055]Component B, weighed: 35 kg Portland cement (grade 42.5), 10 kg white cement, 20 kg 100 mesh quartz sand, 10 kg heavy calcium powder, 3 kg metakaolin, 3 kg latex powder, 1 kg polycarboxylate Acid high-efficiency water reducer; mix and stir the weighed materials to obtain component B for use;

[0056] Component A: Component B is mixed according to the ratio of 1:3, stirred evenly, sprayed on the surface of the hydraulic concrete sample, and dried. The hydraulic concrete sample is 10cmX10cm in size, forming a two-component polymer mortar bond base coat (1). The thickness of the two-component polymer mortar bonding primer (1) is 1 mm.

[0057] Two-component high-strength polymer mortar medium...

Embodiment 2

[0065] Two-component polymer mortar bonded primer (1)

[0066] Component A, weighing: 75 kg of styrene-acrylic emulsion, 35 kg of deionized water, 3 kg of dispersant, 2 kg of antibacterial agent, 3 kg of defoamer; mix and stir the weighed materials to obtain component A for use ;

[0067] Component B, weighing: 45 kg Portland cement (42.5 grade), 20 kg white cement, 35 kg 100 mesh quartz sand, 20 kg heavy calcium powder, 5 kg metakaolin, 5 kg latex powder, 3 kg polycarboxylate Acid high-efficiency water reducer; mix and stir the weighed materials to obtain component B for use;

[0068] Component A: Component B is mixed according to the ratio of 1:3, stirred evenly, sprayed on the surface of the hydraulic concrete sample, and dried. The hydraulic concrete sample is 10cmX10cm in size, forming a two-component polymer mortar bond base coat (1). The thickness of the two-component polymer mortar bonding primer (1) is 1 mm.

[0069] Two-component high-strength polymer mortar medi...

Embodiment 3

[0077] Two-component polymer mortar bonded primer (1)

[0078] Component A, weighing: 70 kg of styrene-acrylic emulsion, 30 kg of deionized water, 2.5 kg of dispersant, 1.5 kg of antibacterial agent, 2.5 kg of defoamer; mix and stir the weighed materials to obtain component A for use ;

[0079] Component B, weighed: 40 kg Portland cement (grade 42.5), 15 kg white cement, 28 kg 100 mesh quartz sand, 17.5 kg heavy calcium powder, 4 kg metakaolin, 4 kg latex powder, 2 kg polycarboxylate Acid high-efficiency water reducer; mix and stir the weighed materials to obtain component B for use;

[0080] Component A: Component B is mixed according to the ratio of 1:3, stirred evenly, sprayed on the surface of the hydraulic concrete sample, and dried. The hydraulic concrete sample is 10cmX10cm in size, forming a two-component polymer mortar bond base coat (1). The thickness of the two-component polymer mortar bonding primer (1) is 0.8mm.

[0081] Two-component high-strength polymer mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com