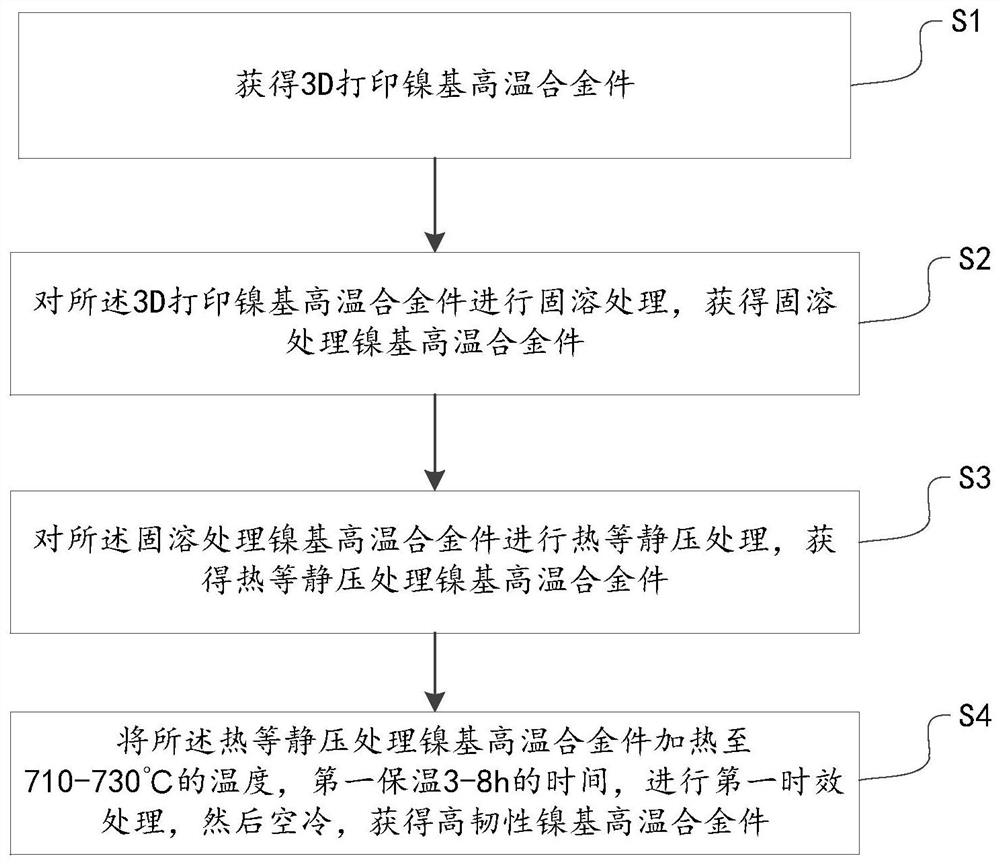

Method for improving toughness of 3D printing nickel-based high-temperature alloy part

A nickel-based superalloy, 3D printing technology, applied in the field of 3D printing, can solve the problems of low high temperature toughness, hidden dangers, easy brittle fracture, etc., to achieve the effect of improving grain boundary strength, improving toughness and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

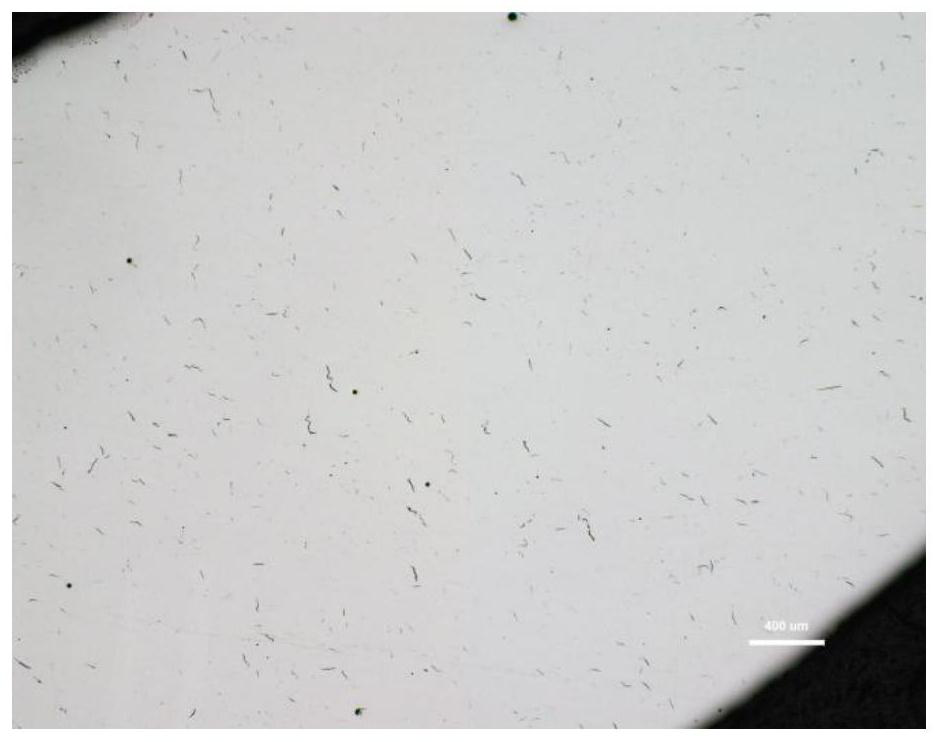

Examples

Embodiment 1

[0060] Example 1 provides a method for improving the toughness of 3D printed nickel-based superalloy parts. The grade of nickel-based superalloy is GH3536, and the thickness is 10mm. The details are as follows:

[0061] (1) Take out the nickel-based superalloy parts after 3D printing; the parts are required to visually inspect the surface state of the parts, and no defects such as cracking and deformation are required; at the same time, the cross-section of the parts should be observed, and the connection surface after forming should not appear unfused or inclusions , cracks and other forming defects, the powder inside the part is cleaned by vibration. Focus on cleaning the support gap and the gap position of the parts; perform dimensional inspection on the height of the parts. Use an air gun with compressed air as the air source to check the cleaning of the residual powder of the parts. It is required to blow air continuously for 3 minutes, and there is no visible powder over...

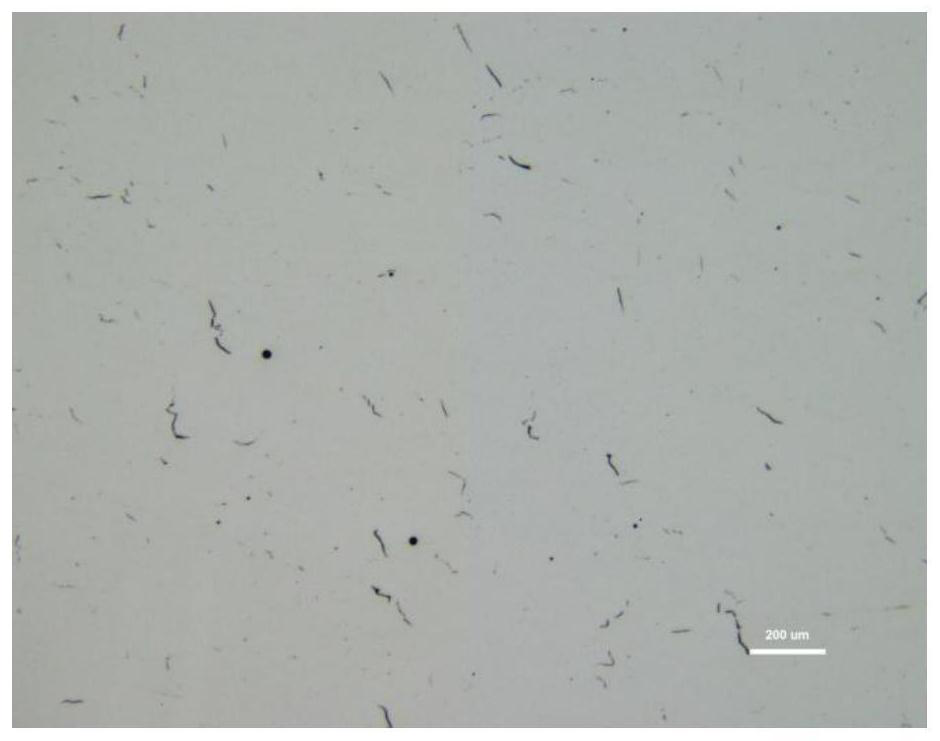

Embodiment 2

[0073] Embodiment 2 provides a method for improving the toughness of 3D printed nickel-based superalloy parts. The grade of nickel-based superalloy is GH3625, and the thickness is 10mm. The details are as follows:

[0074](1) Take out the parts after 3D printing; the parts are required to visually inspect the surface state of the parts, and no defects such as cracking and deformation are required; at the same time, the cross-section of the parts should be observed. , Use vibration to clean the powder inside the part. Focus on cleaning the support gap and the gap position of the parts; perform dimensional inspection on the height of the parts. Use an air gun with compressed air as the air source to check the cleaning of the residual powder of the parts. It is required to blow air continuously for 3 minutes, and there is no visible powder overflow.

[0075] (2) Carry out vacuum solution treatment to the nickel-based superalloy parts in step (1), the solution treatment is three-...

Embodiment 3-4

[0086] Embodiment 3-4 provides a method for improving the toughness of 3D printing nickel-based superalloy parts, with reference to Embodiment 1, the difference from Embodiment 1 is the specific process of solid solution treatment, hot isostatic pressing treatment and aging treatment Different, specifically as shown in Table 1-3, the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com