Fuel cell cathode oxygen reduction catalyst and preparation method and application thereof

A fuel cell cathode and catalyst technology, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve the problems of carrier corrosion and reduce the life of Pt catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

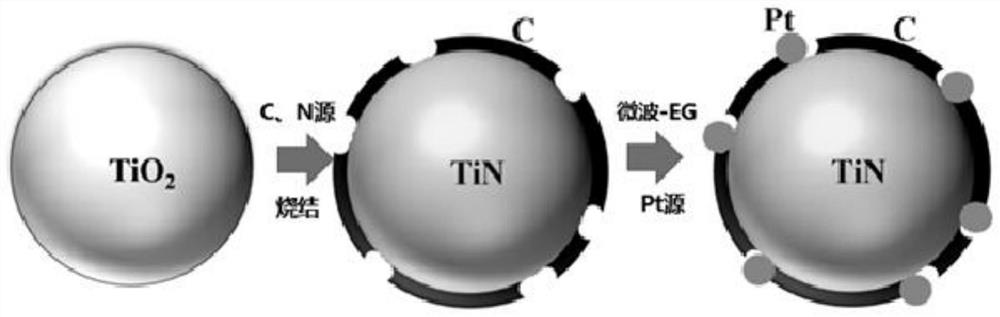

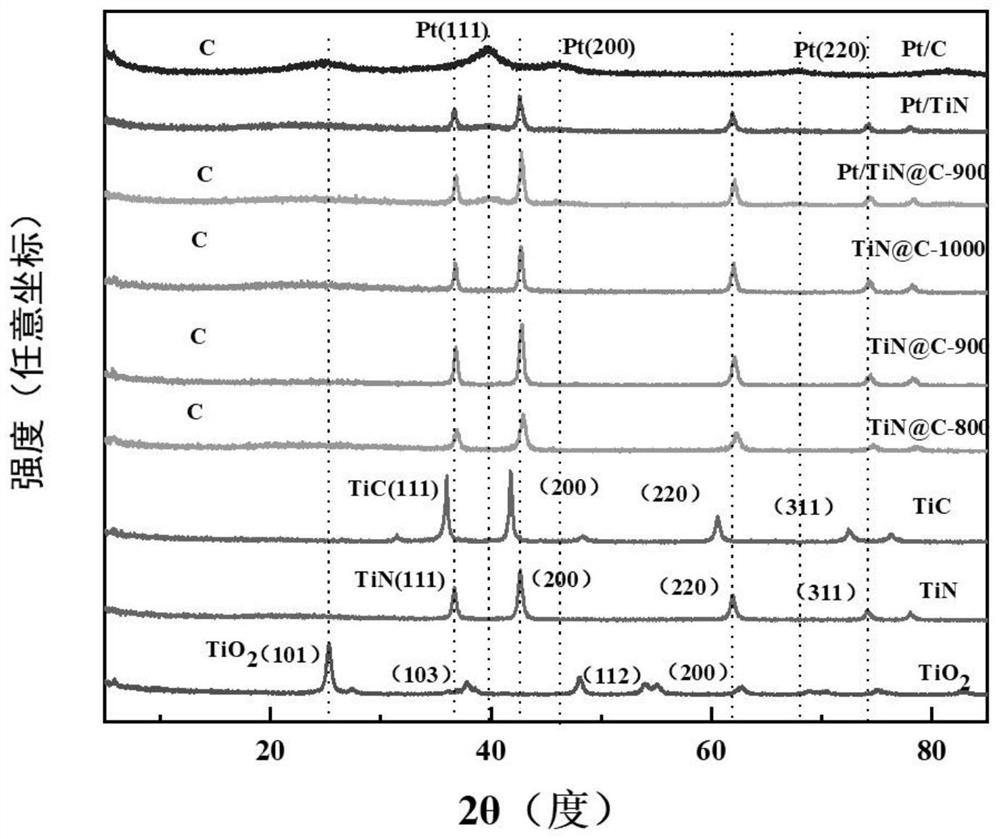

[0040] figure 1 It is a schematic diagram of the preparation principle of the novel long-life Pt / TiN@C oxygen reduction catalyst in the present invention, and the preparation method includes the following steps:

[0041] Step 1, the titanium-containing precursor, the N- and C-containing precursors are mixed uniformly by high-speed ball milling. The titanium-containing precursor is titanium dioxide nanoparticles with a diameter of 5-60nm, the N and C-containing precursors are: guanidine hydrochloride, biuret, melamine or urea, and the mass ratio of the titanium-containing precursor to the C and N-containing precursor is 1:5~1:40.

[0042] In step two, the powder obtained in step one is subjected to high-temperature heat treatment in a vacuum environment, the heat treatment temperature is 700-1100° C., and the heat treatment temperature time is 30-240 minutes. Naturally cool to room temperature.

[0043] In step three, the powder obtained in step two is ground to obtain the T...

Embodiment 1

[0046] In this example, a 10% Pt / TiN@C composite carrier catalyst was prepared.

[0047] A preparation method of a novel long-life Pt / TiN@C oxygen reduction catalyst in this embodiment comprises the following steps:

[0048] (1) Take nano-titanium oxide and guanidine hydrochloride (specifically 1000 mg guanidine hydrochloride and 100 mg nano-titanium oxide particles with a diameter of 5-10 nm) with a mass ratio of 1:10 with an electronic balance and place them in a planetary ball mill for ball milling for 3 hours, so that The guanidine hydrochloride and the titanium oxide are fully and physically mixed uniformly.

[0049] (2) Place the uniformly mixed guanidine hydrochloride and titanium oxide in an alumina / quartz crucible, slowly put it into a tube furnace, and raise the temperature to 900° C. at a rate of 10° C. / min in a vacuum environment, and keep it warm for 2 hours. Perform high-temperature heat treatment, and after the heat preservation is completed, naturally cool to ...

Embodiment 2

[0058] This example is basically the same as Example 1, except for the particle size of titanium oxide.

[0059] Four sets of parallel experiments were designed to change the size of the Ti-containing precursor, that is, 5-10nm titanium oxide, to 20nm, 40nm, 60nm and 70nm respectively, and other conditions and steps remained the same as in Example 1.

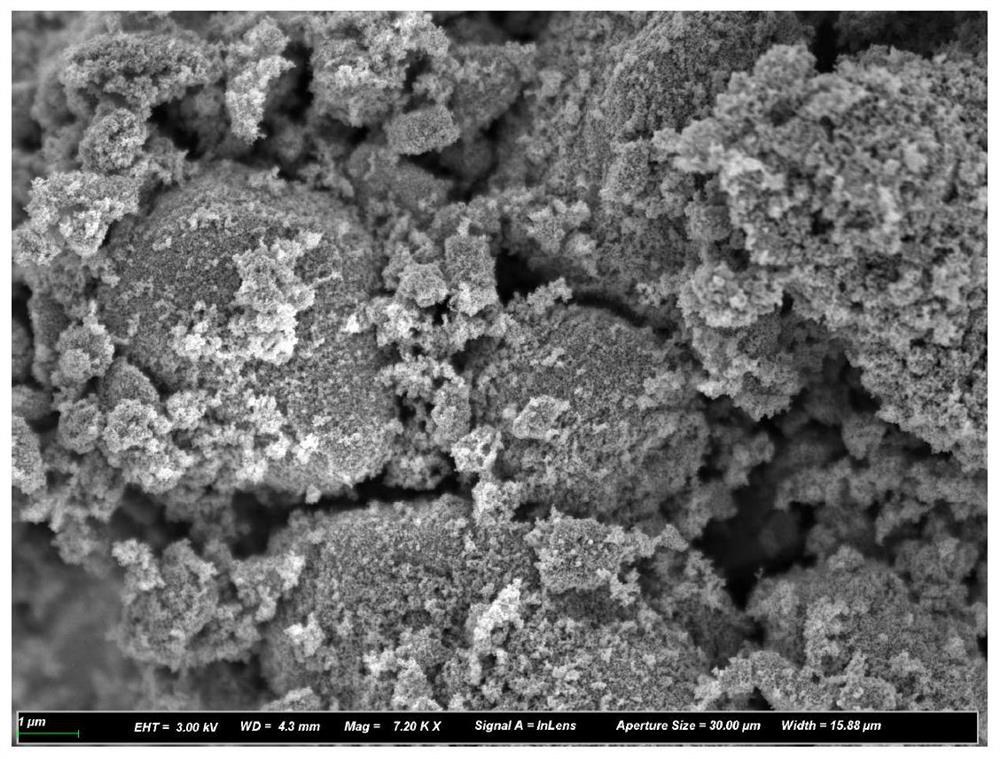

[0060] The particle size of TiN@C nanoparticles obtained after changing the size of the Ti-containing precursor, namely 5-10nm titanium oxide, to 20nm, 40nm and 60nm gradually increased. When the size of the Ti-containing precursor increased to 70nm, the obtained TiN@C The particles reach the submicron level, the specific surface area is too small, and the catalytic performance is poor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com