Waste mineral oil atmospheric and vacuum distillation device based on reduced pressure cutting fractionation

A technology of atmospheric and vacuum distillation and waste mineral oil, which is applied in the field of fractionation and can solve problems such as unfavorable cooling, unfavorable collection, and generation of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

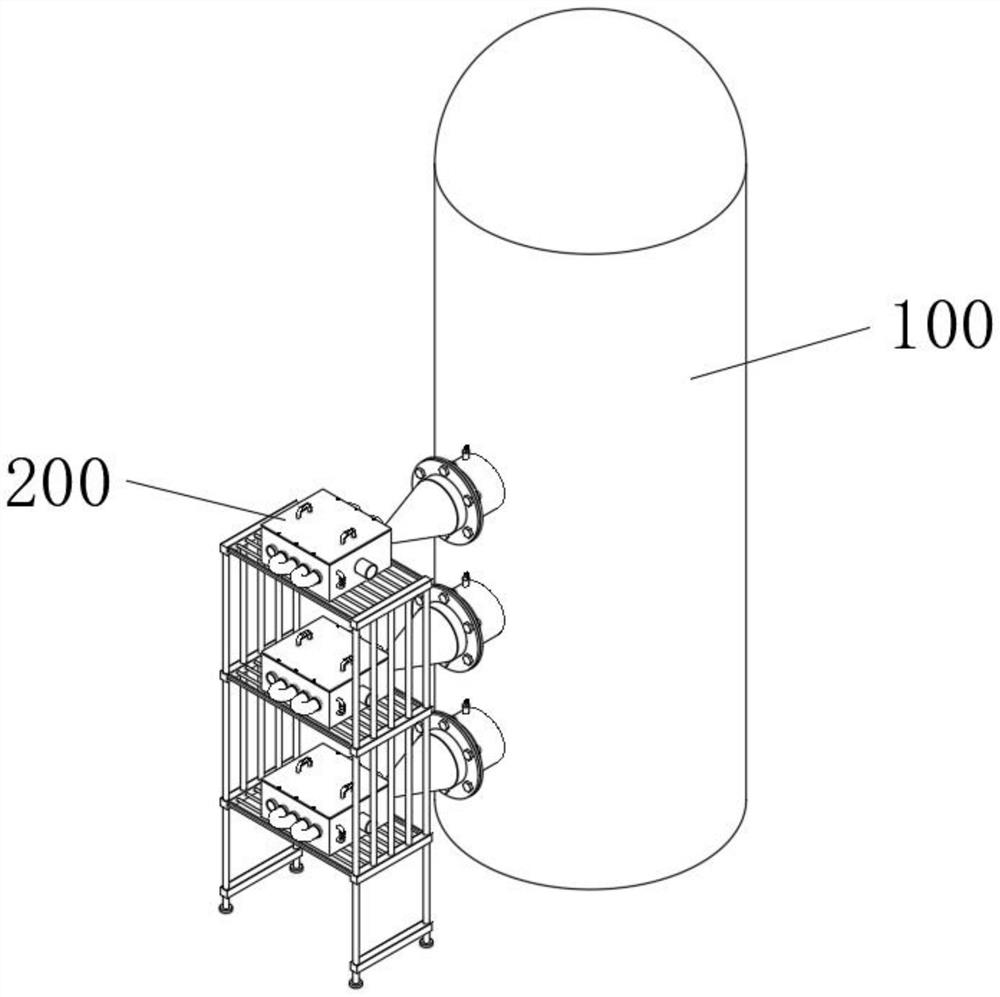

[0054] see Figure 1-Figure 13 As shown, an atmospheric and vacuum distillation unit for waste mineral oil based on vacuum cutting fractionation is provided, including a fractionation structure 100 and a condensation structure 200 installed on the side of the fractionation structure 100, and the fractionation structure 100 includes at least:

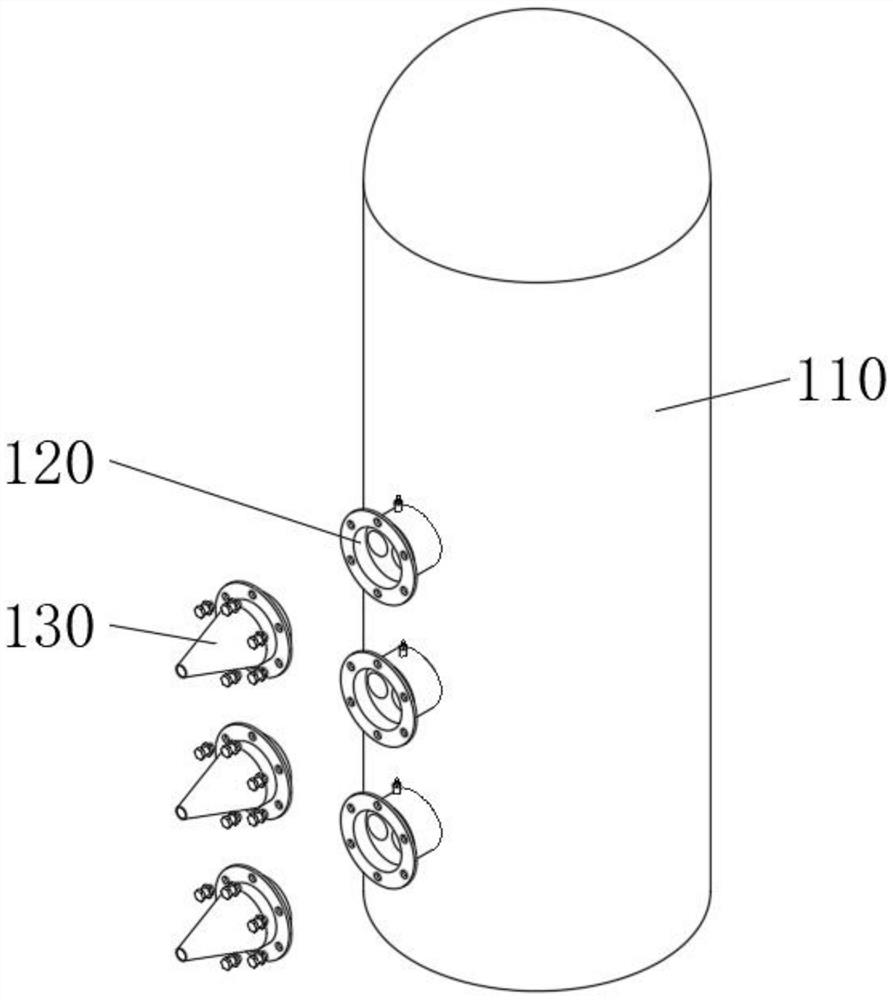

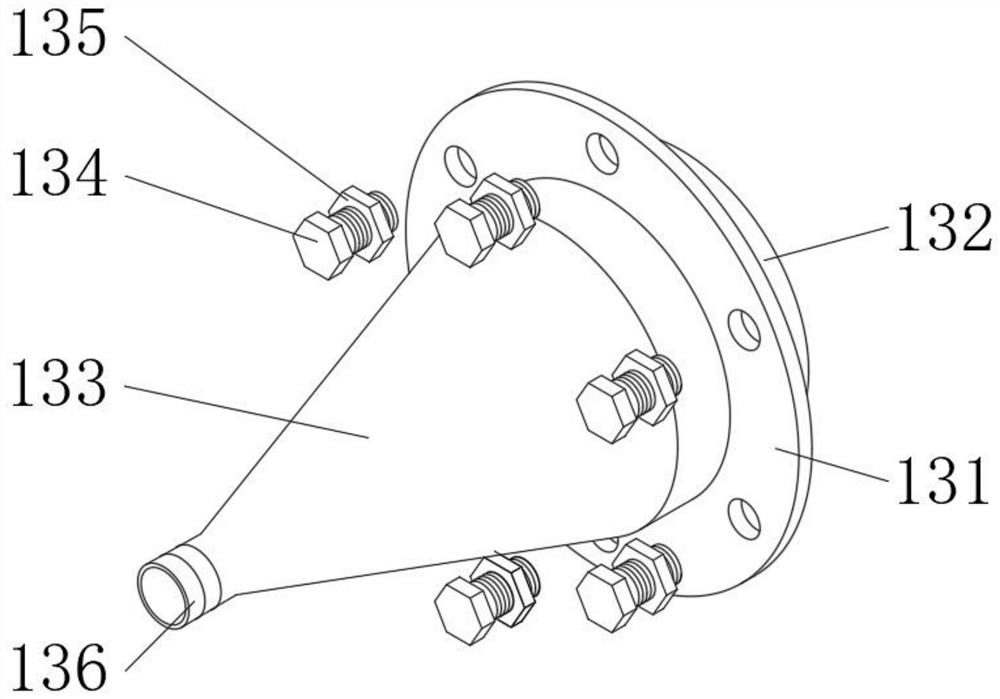

[0055] Fractionation tower 110, fractionation tower is the tower type vapor-liquid device that carries out distillation, is preferably plate tower, and as known to those skilled in the art, fractionation tower system comprises fractionation tower body (generally called cold storage box), ammonia precooler group, Heating and thawing system and liquid oxygen system, etc., the side of the fractionation tower 110 is provided with a plurality of outlets, and the outer side of the fractionation tower 110 is provided with a pipeline structure 120, and the pipeline structure 120 includes an installation pipe 121, which is connected to the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com