Low-smoke halogen-free flame-retardant insulating material for cable

A technology for insulating materials and cables, applied in the field of low-smoke halogen-free flame retardant insulating materials for cables, can solve the problems that inorganic flame retardants cannot provide safety protection, poor safety guarantee, aging and damage of insulating materials, etc., and achieve excellent resistance to Tear strength, guaranteed toughness and elasticity, longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

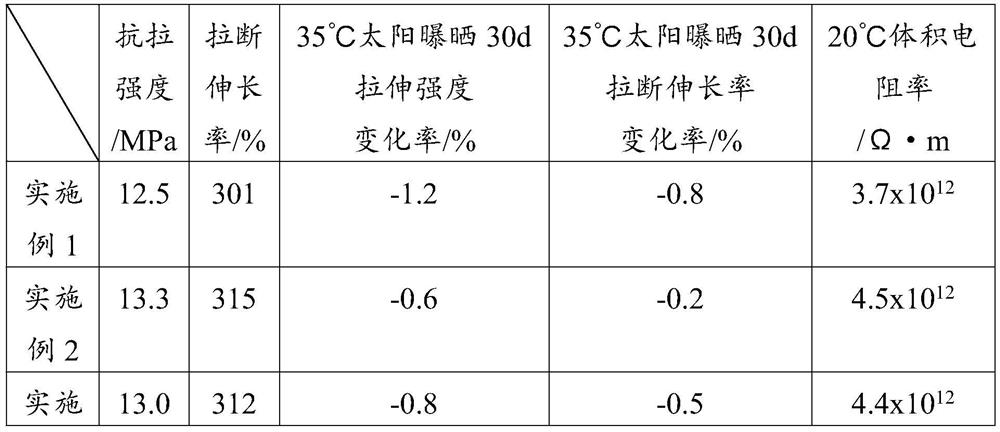

Embodiment 1

[0027] The invention provides a low-smoke, halogen-free, flame-retardant insulating material for cables, wherein the main materials used include by weight: 60 parts of EPDM rubber compound, 35 parts of EVA rubber compound, 5 parts of silane coupling agent Parts, 8 parts of filler, 1 part of aluminum nitride, 2 parts of nano molybdenum disulfide, 20 parts of aluminum hydroxide, 15 parts of ammonium polyphosphate, 12 parts of liquid silica gel, 6 parts of ammonium hydrogen oxalate, 5 parts of nylon fiber, 4 parts of vulcanizing agent 7 parts, 7 parts of anti-aging agent, 6 parts of foaming agent and 2 parts of foam stabilizer;

[0028] The filler is composed of expandable graphite, nano-calcium carbonate and ceramic powder, and the volume ratio of expandable graphite, white carbon black and ceramic powder is set as expandable graphite: nano-calcium carbonate: ceramic powder = 1:2: 1.

[0029] Preferably, the silane coupling agent is set to be vinyl silane.

[0030] Preferably,...

Embodiment 2

[0042] The invention provides a low-smoke halogen-free flame-retardant insulating material for cables, wherein the main materials used include by weight: 63 parts of EPDM rubber compound, 38 parts of EVA rubber compound, 6 parts of silane coupling agent Parts, 10 parts of filler, 2 parts of aluminum nitride, 3 parts of nano molybdenum disulfide, 25 parts of aluminum hydroxide, 20 parts of ammonium polyphosphate, 15 parts of liquid silica gel, 8 parts of ammonium hydrogen oxalate, 6 parts of nylon fiber, 5 parts of vulcanizing agent 10 parts, anti-aging agent, 6.5 parts of blowing agent and 2.5 parts of foam stabilizer;

[0043] The filler is composed of expandable graphite, nano calcium carbonate and ceramic powder, and the volume ratio of expandable graphite, white carbon black and ceramic powder is set to expandable graphite: nano calcium carbonate: ceramic powder = 2:2: 1.

[0044] Preferably, the silane coupling agent is set to be aminosilane.

[0045] Preferably, the ex...

Embodiment 3

[0057] The invention provides a low-smoke halogen-free flame-retardant insulating material for cables, wherein the main materials used include by weight: 66 parts of EPDM rubber compound, 40 parts of EVA rubber compound, 8 parts of silane coupling agent Parts, 12 parts of filler, 3 parts of aluminum nitride, 4 parts of nano molybdenum disulfide, 30 parts of aluminum hydroxide, 30 parts of ammonium polyphosphate, 18 parts of liquid silica gel, 9 parts of ammonium hydrogen oxalate, 10 parts of nylon fiber, 6 parts of vulcanizing agent 14 parts, anti-aging agent, 7 parts of foaming agent and 3 parts of foam stabilizer;

[0058] The filler is composed of expandable graphite, nano calcium carbonate and ceramic powder, and the volume ratio of expandable graphite, white carbon black and ceramic powder is set to expandable graphite: nano calcium carbonate: ceramic powder = 2:3: 1.

[0059] Preferably, the silane coupling agent is set as methacryloyloxysilane.

[0060] Preferably, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com