Battery diaphragm, preparation method thereof, and impregnation equipment of polyimide porous membrane

A polyimide-based film, polyimide technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of diaphragm piercing assembly strength, burning diaphragm, diaphragm melting, etc. Wetting ability and liquid retention performance, improving ionic conductivity, and avoiding the effect of poor air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

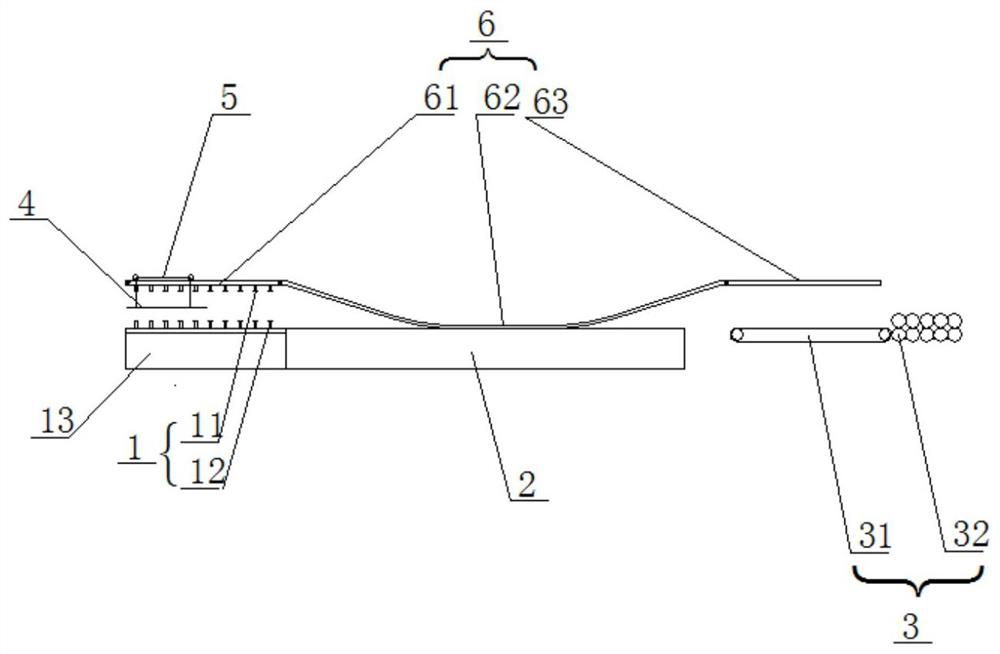

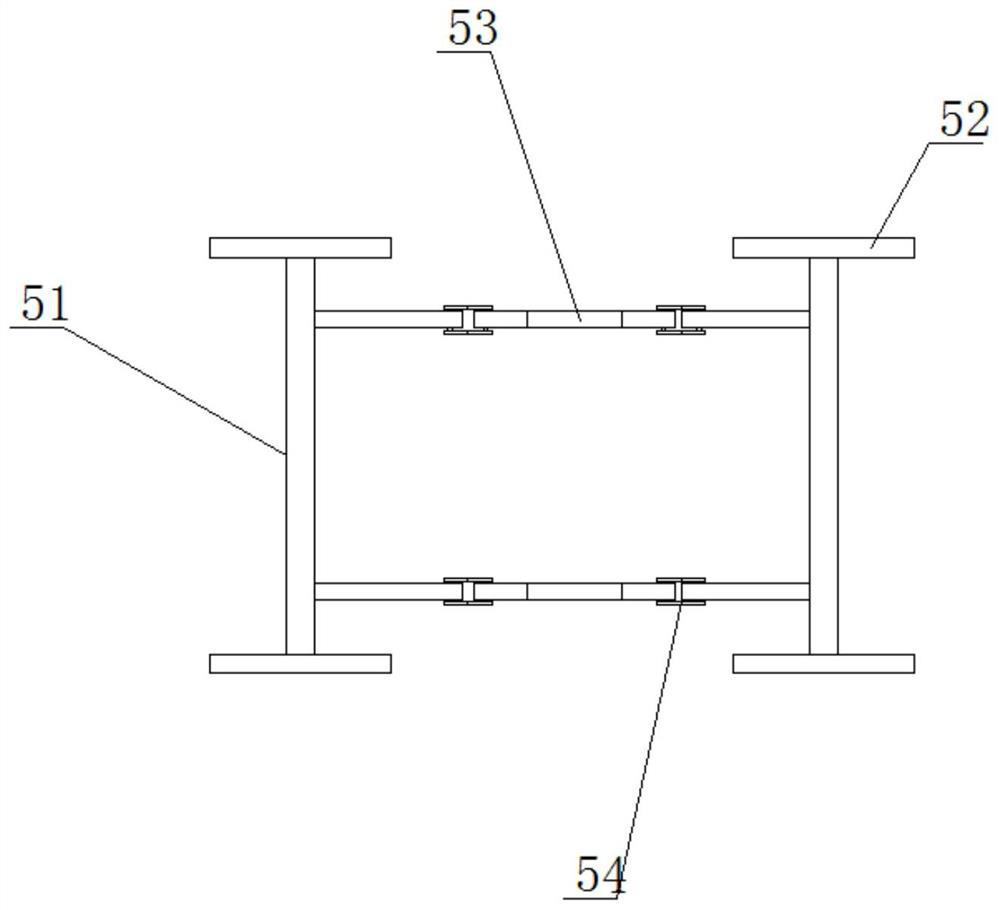

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a battery separator, comprising a polyolefin porous film layer and a polyimide porous film layer,

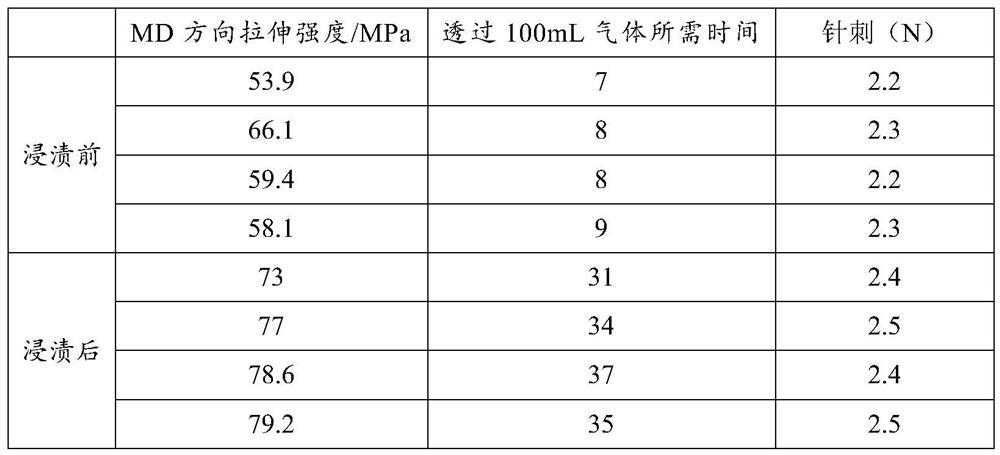

[0047] The polyimide porous film layer comprises a polyimide base film and an impregnation layer coated on the outside of the polyimide base film, and the impregnation layer comprises a polyimide resin or a phenolic resin or an aramid resin and the like. High-temperature reinforced resin, the high-temperature-resistant reinforced resin refers to a resin whose temperature resistance is greater than 280°C. The piercing strength of the polyimide porous film layer is 0.68-3N, and the MD direction tensile strength of the porous diaphragm is greater than twice that of the polyimide base film. In this embodiment, the polyimide The MD direction tensile strength of the porous film layer is greater than 70MPa, the TD direction tensile strength of the porous diaphragm is greater than 50MPa, and the air permeability of the polyimide porous film layer is 30-12...

Embodiment 2

[0067] This embodiment provides a battery separator, comprising a polyolefin porous film layer and a polyimide porous film layer, the polyimide porous film layer comprising a polyimide base film and a polyimide base film coated The outer impregnation layer, the impregnation layer includes polyimide resin, phenolic resin or aramid resin and other high temperature resistant reinforced resin, the high temperature resistant reinforced resin refers to a resin with a temperature resistance greater than 280°C. The piercing strength of the polyimide porous membrane layer is 0.68N, and the tensile strength of the porous diaphragm in the MD direction is greater than twice that of the polyimide base membrane.

[0068] It also includes an aluminum oxide coating and an adhesive layer between the polyimide porous film layer and the polyolefin porous film layer, and the polyolefin porous film layer and the polyimide porous film layer pass through the aluminum oxide coating, The adhesive laye...

Embodiment 3

[0076] This embodiment provides a battery separator, comprising a polyolefin porous film layer and a polyimide porous film layer, the polyimide porous film layer comprising a polyimide base film and a polyimide base film coated The outer impregnation layer, the impregnation layer includes polyimide resin, phenolic resin or aramid resin and other high temperature resistant reinforced resin, the high temperature resistant reinforced resin refers to a resin with a temperature resistance greater than 280°C. The piercing strength of the polyimide porous membrane layer is 2.4N, and the tensile strength of the porous diaphragm in the MD direction is greater than twice that of the polyimide base membrane.

[0077] It also includes an aluminum oxide coating and an adhesive layer between the polyimide porous film layer and the polyolefin porous film layer, and the polyolefin porous film layer and the polyimide porous film layer pass through the aluminum oxide coating, The adhesive layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com