Anisotropic self-reinforced organic silicon composite material and preparation method thereof

An anisotropic, composite material technology, applied in the field of anisotropic self-reinforced organic silica gel composite material and its preparation, can solve the problems of increasing process difficulty and complexity, increasing preparation cost, material loss and waste, etc., and achieving huge applications Value and market potential, good biocompatibility, the effect of meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An anisotropic self-reinforced organic silica gel composite material, which includes the following raw materials: calculated by mass percentage, containing organic silicon polymer monomer (83.4%), organic silicon crosslinking agent (8.3%), liquid filling substance (8.3%) %).

[0032] The silicone polymer monomer is Sylgard184 base, and the silicone crosslinking agent is Sylgard184 linker.

[0033] The liquid filling substance is glycerol.

[0034] A method for preparing an anisotropic self-reinforced organic silica gel composite material, comprising the following steps:

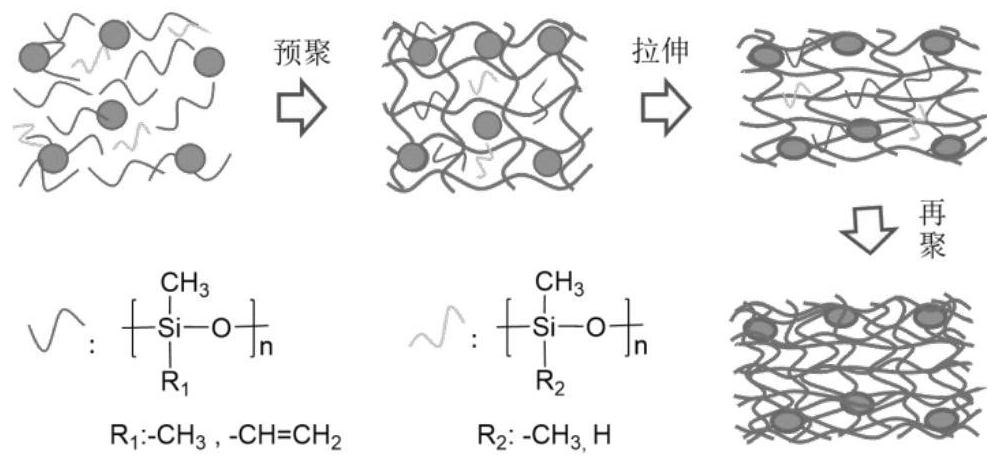

[0035] (1) After fully mixing the silicone polymer monomer (83.4wt%) containing the Pt catalyst, the silicone crosslinking agent (8.3wt%), and the liquid filling material (8.3wt%), react at 100°C for 0.17 h obtains the pre-polymerized material;

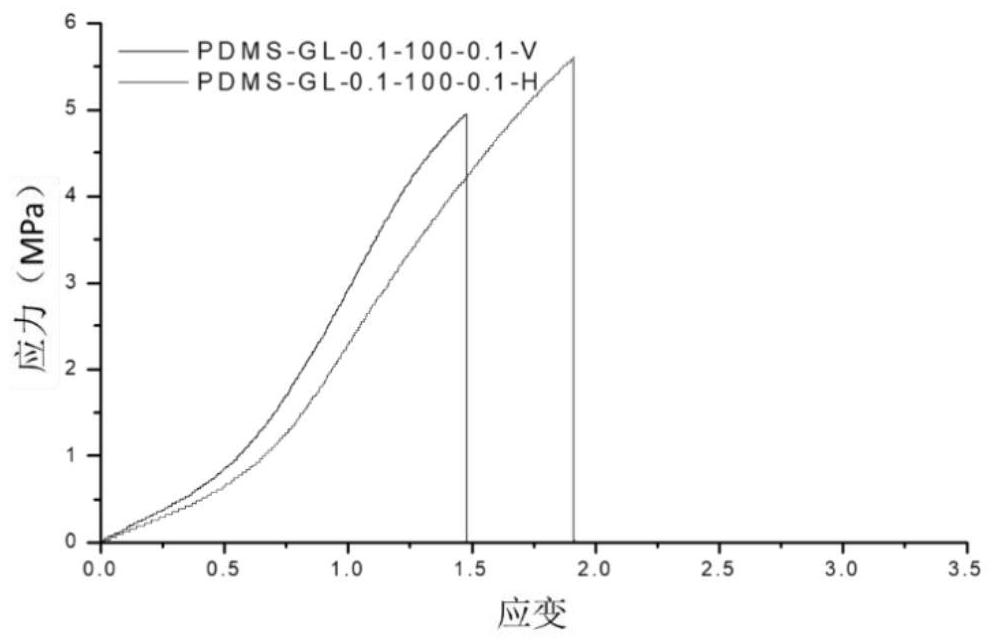

[0036] (2) Stretch the pre-polymerized material by 100%, and then carry out a further 2h polymerization reaction at 100° C. to obtain an anisotropic self-r...

Embodiment 2

[0038] An anisotropic self-reinforced organic silica gel composite material, which includes the following raw materials: calculated by mass percentage, containing organic silicon polymer monomer (84.5%), organic silicon crosslinking agent (7%), liquid filling substance (8.5%) %).

[0039] The silicone polymer monomer is Sylgard184 base (Dow Corning), and the silicone crosslinker is Sylgard184 linker (Dow Corning).

[0040] The liquid filling substance is glycerol.

[0041] A method for preparing an anisotropic self-reinforced organic silica gel composite material, comprising the following steps:

[0042] (1) A Pt catalyst containing organosilicon polymer monomer (84.5wt%), organosilicon crosslinking agent (7wt%), and liquid filling material (8.5wt%). After fully mixing, react at 25°C for 24 hours to obtain a pre-polymerized material;

[0043](2) Stretching the pre-polymerized material by 100%, and then further polymerizing at 100° C. for 2 hours to obtain an anisotropic sel...

Embodiment 3

[0045] An anisotropic self-reinforced organic silica gel composite material, which includes the following raw materials: calculated by mass percentage, containing organic silicon polymer monomer (86%), organic silicon crosslinking agent (5.4%), liquid filling substance (8.6%) %).

[0046] The silicone polymer monomer is Sylgard184 base (Dow Corning), and the silicone crosslinker is Sylgard184 linker (Dow Corning).

[0047] The liquid filling substance is glycerol.

[0048] A method for preparing an anisotropic self-reinforced organic silica gel composite material, comprising the following steps:

[0049] (1) Fully stir and mix the silicone polymer monomer (86wt%), silicone crosslinking agent (5.4wt%), and liquid filler (8.6wt%), and then react at 100°C for 0.18h to obtain a prepolymerized material ;

[0050] (2) Stretching the pre-polymerized material by 100%, and then further polymerizing at 100° C. for 2 hours to obtain an anisotropic self-reinforced organic silica gel co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com