Anti-attenuation low-melting-point polyester chip prepared by one-step spinning method and preparation method of anti-attenuation low-melting-point polyester chip

A low-melting polyester, spinning technology, applied in the direction of one-component copolyester rayon and other directions, can solve the problems of de-orientation effect, poor thermal crystallization performance, strength attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

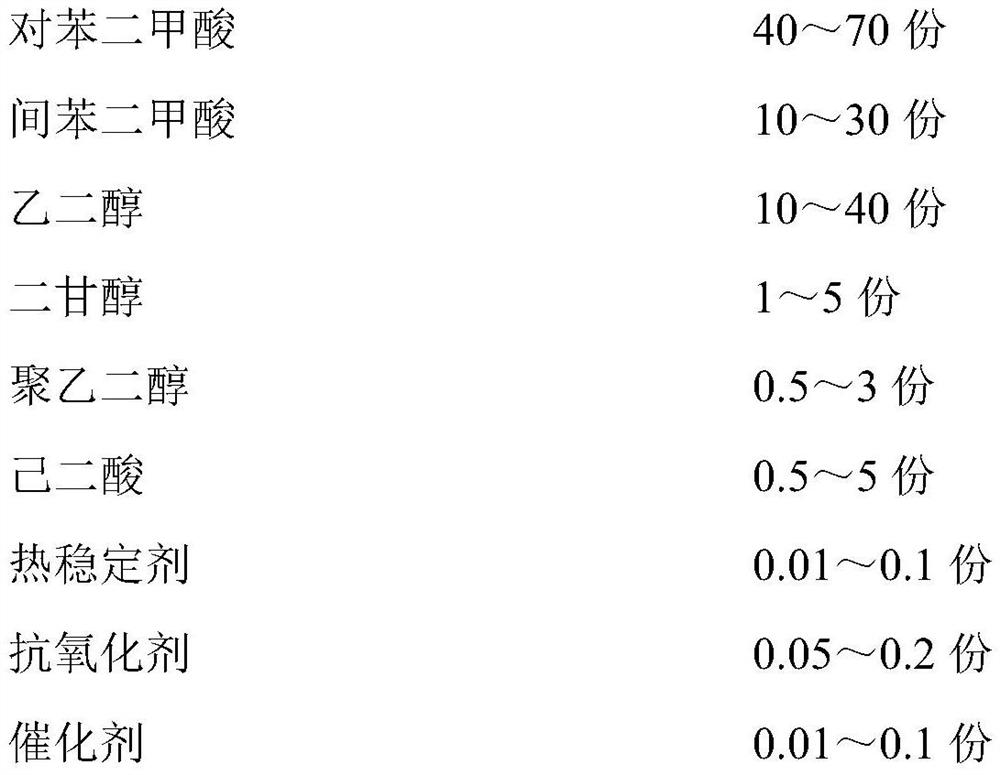

Method used

Image

Examples

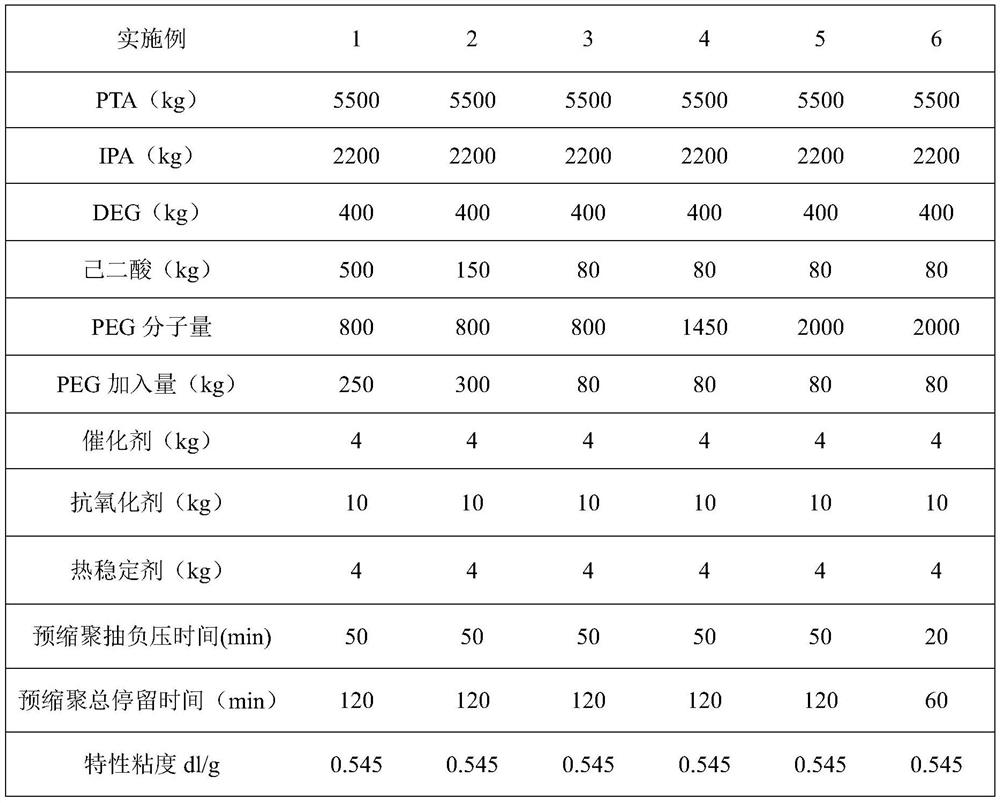

Embodiment 1

[0028] The preparation method of the anti-attenuation type low-melting point polyester chip in the present embodiment is as follows:

[0029] Step 1, one esterification

[0030] Step 1.1. Add 558kg of IPA and 400kg of DEG (alkyd molar ratio: 1.12) to the slurry preparation kettle. After stirring evenly, add the esterification kettle through a metering pump to carry out the esterification reaction. The esterification temperature is controlled at 235-240 ℃, the esterification pressure is controlled at normal pressure, and the esterification reaction of DEG and part of IPA is completed when the esterification water is received to 109 kg (90% esterification rate).

[0031] Step 1.2, after stirring the remaining 1642kg of IPA, 5500kg of PTA, 500kg of adipic acid and 3455kg of EG (alcohol-acid molar ratio 1.2) evenly, add an esterification kettle through a metering pump to carry out the esterification reaction, the esterification temperature The temperature is controlled at 235-240...

Embodiment 2

[0040] The preparation process of this example is the same as Example 1, the difference is that in Example 1, the total amount of adipic acid is 500kg, PEG-800 is 250kg, and EG is 3455kg; in this example, the total amount of adipic acid is 150kg, PEG- 800 is 300kg, the total amount of EG is 3275kg, and the remaining distribution esterification process, alkyd acid molar ratio, and auxiliary agent dosage are all carried out according to Example 1.

Embodiment 3

[0042] The preparation process of this example is the same as Example 1, the difference is that in Example 1, the total amount of adipic acid is 500kg, PEG-800 is 250kg, and EG is 3455kg; in this example, the total amount of adipic acid is 80kg, PEG- 800 is 80kg, the total amount of EG is 3239kg, and the rest of the distribution esterification process, alkyd molar ratio, and auxiliary agent dosage are all carried out according to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com