Electro-spinning micro-nanofiber device and method for preparing micro-nanofiber

A micro-nano fiber, electrospinning technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problem of difficult parameter stable regulation, limited application development, and difficulty in mass production of diameter and directional electrospinning fibers. and other problems, to achieve the effects of enriching varieties, reducing high-voltage electric fields, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 8g of polyε-caprolactone, dissolve it in 20ml of dichloromethane as a solution, and stir it magnetically at room temperature for 60min to obtain a colorless and transparent electrospinning stock solution.

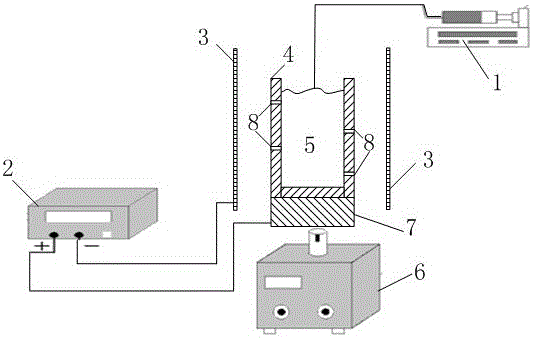

[0038] Inject the prepared electrospinning stock solution into a 5ml syringe, connect the syringe to the injection needle through a silicone tube, connect the positive stage of the high-voltage electrostatic generator to the two-hole spinneret metal sheet, and the ground stage to the external receiving device, and fix the spinneret On the rotary device, the rotary speed is adjusted to 70RPM, the flow rate of the syringe pump is adjusted to 20ml / h, the radius of the receiving device is selected to be 9cm, and then the rotary device and the high-voltage power supply are started at the same time, and the voltage is set to 15kv, and multiple yields and Directional electrospun fibers.

Embodiment 2

[0040] Weigh a solution with a mass fraction of PVP of 15%, use water as a solvent, and add 0.1g Fe 3 o 4 With 0.5g tetracycline drug, magnetically stirred at room temperature for 60min to obtain a colorless and transparent electrospinning stock solution.

[0041] Inject the prepared electrospinning stock solution into a 5ml syringe, connect the syringe to the injection needle through a silicone tube, connect the positive stage of the high-voltage electrostatic generator to the four-hole spinneret bearing, and the ground stage to the external receiving device, and fix the spinneret on On the rotary device, the rotary speed is adjusted to 180RPM, the flow rate of the syringe pump is adjusted to 15ml / h, the radius of the receiving device is selected to be 5cm, and then the rotary device and the high-voltage power supply are started at the same time, and the voltage is set to 12kv, and multiple yields and directions can be collected. permanent electrospun fibers.

Embodiment 3

[0043] Weigh 5g polyvinylpyrrolidone, dissolve it in 25ml ethanol, add 0.1g Fe 3 o 4 , magnetically stirred at room temperature for 60 minutes to obtain a brown electrospinning stock solution with evenly distributed magnetic powder.

[0044] Inject the prepared electrospinning stock solution into a 5ml syringe, connect the syringe to the injection needle through a silicone tube, connect the positive stage of the high-voltage electrostatic generator to the four-hole spinneret bearing, and the ground stage to the external receiving device, and fix the spinneret on On the rotary device, the rotary speed is adjusted to 3000RPM, the flow rate of the syringe pump is adjusted to 30ml / h, the radius of the receiving device is selected to be 13cm, and then the rotary device and the high-voltage power supply are started at the same time, and the voltage is set to 18kv to collect multiple yields and directions. permanent electrospun fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com