Functional edible oil as well as preparation method and application thereof

An edible oil and functional technology, applied in the direction of edible oil/fat, application, food science, etc., can solve the problem of no optimization and determination of fatty acid composition and structure, no improvement of physiological effects of glucose and lipid metabolism disorders, no medium and long carbon It can improve the disorders of glucose and lipid metabolism, improve health and living standards, and achieve significant social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The fatty acids of camphor tree seed kernel oil, soybean oil and linseed oil used in this embodiment are raw materials, and their composition and distribution are shown in Table 2, Table 3 and Table 4 for details. According to the mass ratio of medium carbon chain fatty acid to long carbon chain fatty acid, it is 1.9, 2.3, 3.0, 4.0 (corresponding medium carbon chain fatty acid content is about 65%w / w, 70%w / w, 75%w / w, 80% %w / w), linoleic acid and linolenic acid mass ratio are 0.5, take appropriate amount of camphor tree seed oil, soybean oil and linseed oil respectively in different esterification reactors, and press 10% ( w / w) Add lipase Staphylococcus capraelipase. The reaction temperature is 40°C, and the stirring reaction time is 4h. After the three-basic transesterification reaction, the lipase in the reaction solution was separated, and the tribasic transesterification rate, equivalent carbon number and freezing point of functional edible oil were measured, and th...

Embodiment 2

[0124] In this example, according to the mass ratio of medium-carbon chain fatty acid and long-chain fatty acid as 3.0, and the mass ratio of linoleic acid to linolenic acid as 0.5, 1.0, 2.0, 4.0, appropriate amounts of camphor tree seed oil, soybean oil and Linseed oil was placed in different esterification reactors, and lipase Staphylococcus capraelipase was added according to 10% (w / w) of the mixed oil mass. The reaction temperature is 40°C, and the stirring reaction time is 4h. After the tribasic transesterification reaction finishes, separate the lipase in the reaction liquid, measure the freezing point of tribasic transesterification rate, equivalent carbon number and functional edible oil, obtain medium carbon chain fatty acid and long carbon chain fatty acid mass ratio to be 3.0, sub- The mass ratios of oleic acid to linolenic acid are 0.5, 1.0, 2.0, 4.0, respectively, the tribasic transesterification rates are 72.13%, 71.78%, 71.33%, 70.92%, respectively, and the trig...

Embodiment 3

[0159] In this example, according to the mass ratio of medium carbon chain fatty acid to long carbon chain fatty acid as 3.0, and the mass ratio of linoleic acid to linolenic acid as 0.5, appropriate amount of camphor tree seed oil, soybean oil and linseed oil were weighed in different esterification In the reactor, add lipase Staphylococcus caprae lipase according to 10% (w / w) of the mass of the mixed oil. The reaction temperature is 40°C, and the stirring reaction time is 4h. After the three-basic transesterification reaction, the lipase in the reaction solution is separated to obtain a functional edible oil with a mass ratio of medium-carbon-chain fatty acid to long-chain fatty acid of 3.0 and a mass ratio of linoleic acid to linolenic acid of 0.5.

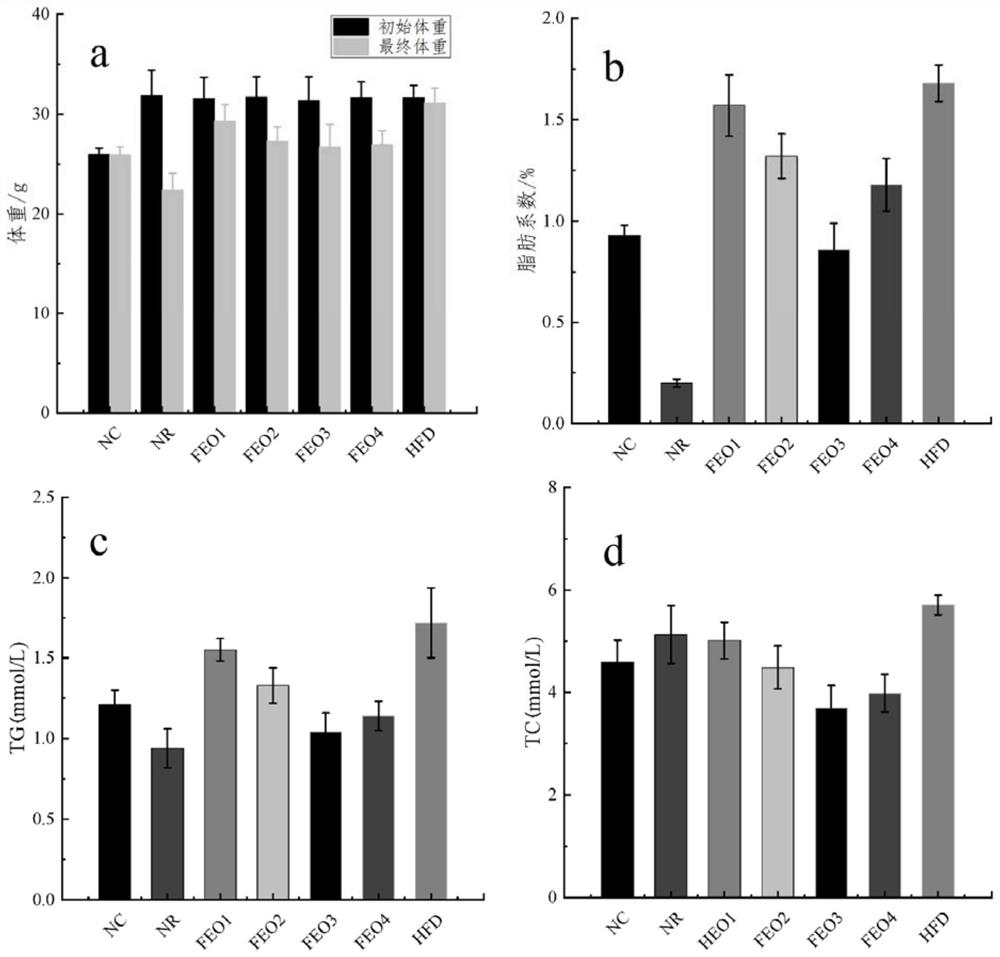

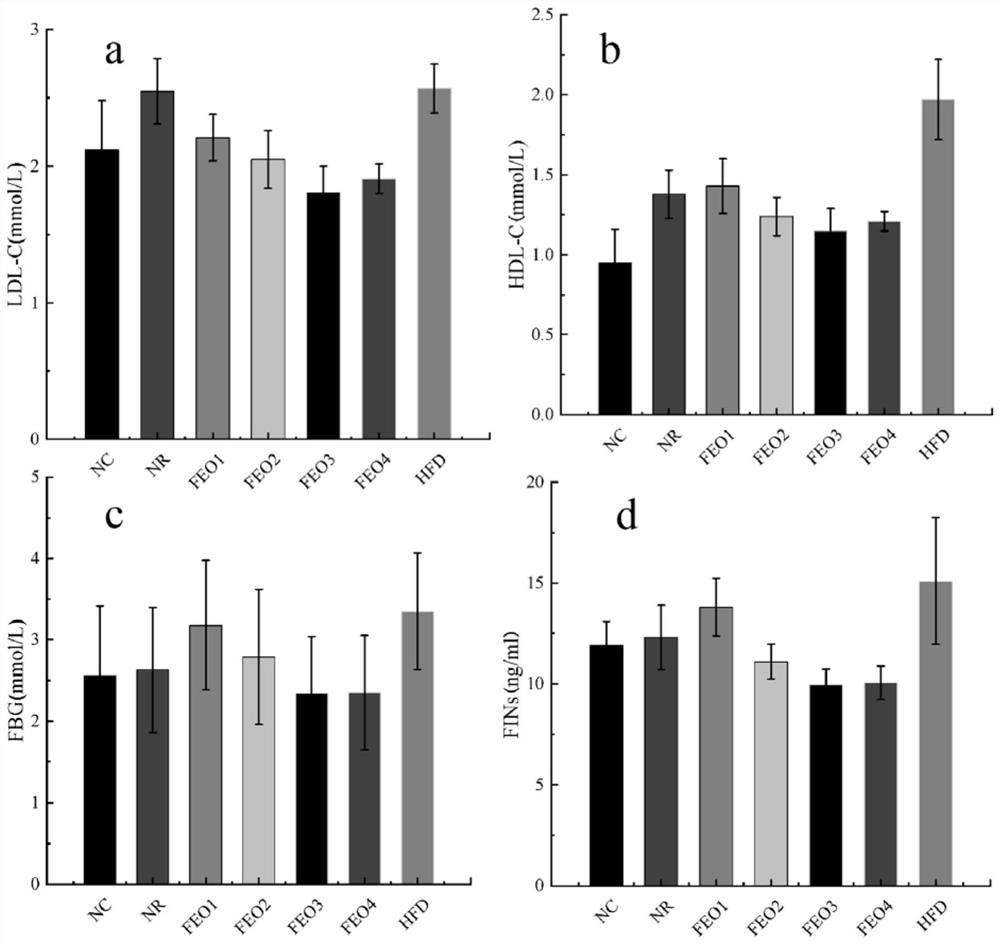

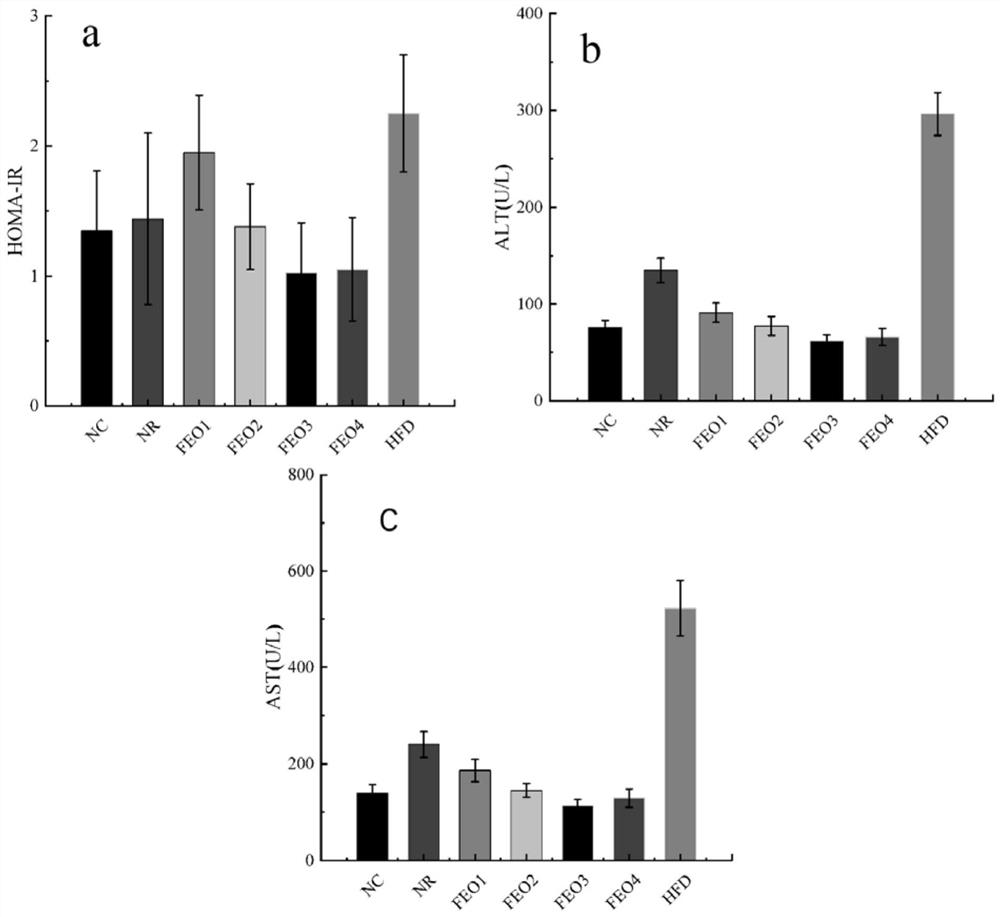

[0160]C57BL / 6 male mice aged 3-4 weeks and weighing 13-16 g were used in the experiment. During the experiment, the mice were fed in a standard cage with free access to food and water, 12h / 12h day and night cycle light, the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com