High-temperature-resistant TPEE/ETFE composite material and preparation method thereof

A technology of composite materials and high temperature resistance, applied in the field of composite materials, can solve the problems that are difficult to meet the use of wires and cables, and achieve the effects of low dielectric loss, low dielectric constant, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

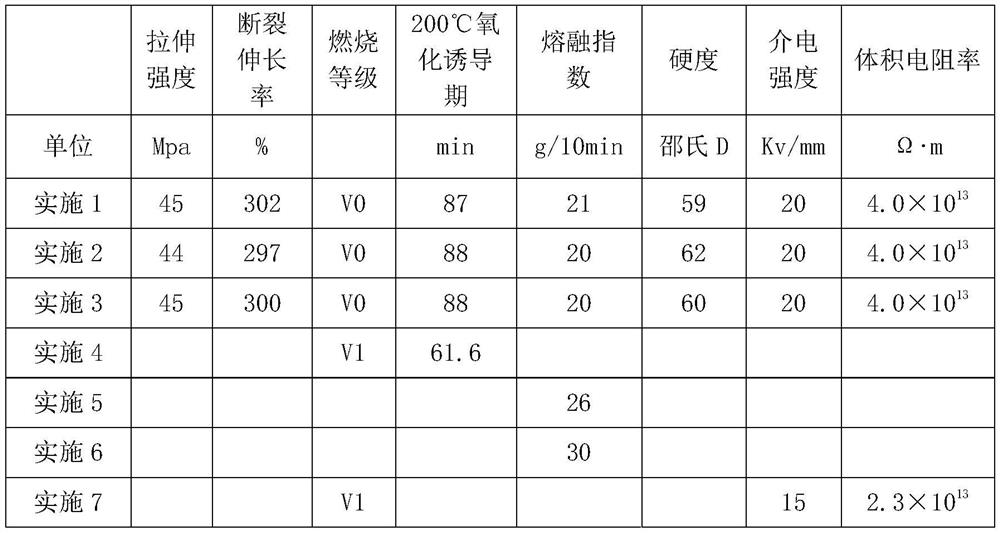

Examples

Embodiment 1

[0065] Embodiment 1 of the present invention specifically provides a high temperature resistant TPEE / ETFE composite material, the raw materials of the composite material include, in parts by weight, 50 parts of PEE, 5 parts of ETFE, 5 parts of composite flame retardant, and 0.1 part of antioxidant , 0.1 parts of lubricant, 5 parts of compatibilizer;

[0066] The hardness of the TPEE is 55 Shore D; the TPEE is TPEE BT-1155D;

[0067] The melting temperature of the ETFE is 210°C; the ETFE is ETFE 750;

[0068] The composite flame retardant is a mixture of phosphorus-based flame retardants, nitrogen-based flame retardants, and diquat; wherein, the weight ratio of the phosphorus-based flame retardants, nitrogen-based flame retardants, and diquat is 1.2:1:1 The phosphorus-based flame retardant is xylyl phosphate; the nitrogen-based flame retardant is melamine cyanurate;

[0069] The antioxidant is a mixture of semi-hindered phenolic antioxidants, phosphite antioxidants, and thioe...

Embodiment 2

[0074] Embodiment 2 of the present invention specifically provides a high temperature resistant TPEE / ETFE composite material, the raw materials of the composite material include, in parts by weight, 80 parts of PEE, 20 parts of ETFE, 10 parts of composite flame retardant, and 0.5 parts of antioxidant , 1 part lubricant, 10 parts compatibilizer;

[0075] The hardness of the TPEE is 55 Shore D; the TPEE is TPEE BT-1155D;

[0076] The melting temperature of the ETFE is 2210°C; the ETFE is ETFE 750;

[0077] The composite flame retardant is a mixture of phosphorus-based flame retardants, nitrogen-based flame retardants, and diquat; wherein, the weight ratio of the phosphorus-based flame retardants, nitrogen-based flame retardants, and diquat is 1.6:1.2:1 The phosphorus-based flame retardant is xylyl phosphate; the nitrogen-based flame retardant is melamine cyanurate;

[0078] The antioxidant is a mixture of semi-hindered phenolic antioxidants, phosphite antioxidants, and thioeth...

Embodiment 3

[0083] Embodiment 3 of the present invention specifically provides a high temperature resistant TPEE / ETFE composite material, the raw materials of the high temperature resistant TPEE / ETFE composite material include, in parts by weight, 68 parts of TPEE, 15 parts of ETFE, 7 parts of composite flame retardant, 0.3 parts of antioxidant, 0.5 parts of lubricant, 7.3 parts of compatibilizer;

[0084] The hardness of the TPEE is 55 Shore D; the TPEE is TPEE BT-1155D;

[0085] The melting temperature of the ETFE is 210°C; the ETFE is ETFE 750;

[0086] The composite flame retardant is a mixture of phosphorus-based flame retardants, nitrogen-based flame retardants, and diquat; wherein, the weight ratio of the phosphorus-based flame retardants, nitrogen-based flame retardants, and diquat is 1.4:1.1:1 The phosphorus-based flame retardant is xylyl phosphate; the nitrogen-based flame retardant is melamine cyanurate;

[0087] The antioxidant is a mixture of semi-hindered phenolic antioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com