Cotton blending machine for flax spinning processing

A flax spinning and cotton blending machine technology, which is applied in the fields of fiber mixing, textile and papermaking, fiber processing, etc., can solve the problem that the finished material has not been treated with impurities, the cotton blending device cannot meet the actual needs, and the iron material cannot be removed. Metal and other problems, to achieve the effect of good cotton blending effect, safe use and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

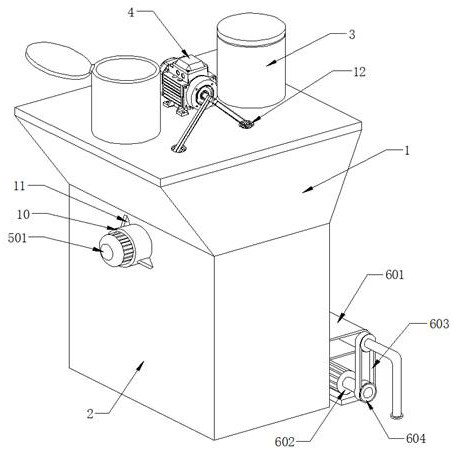

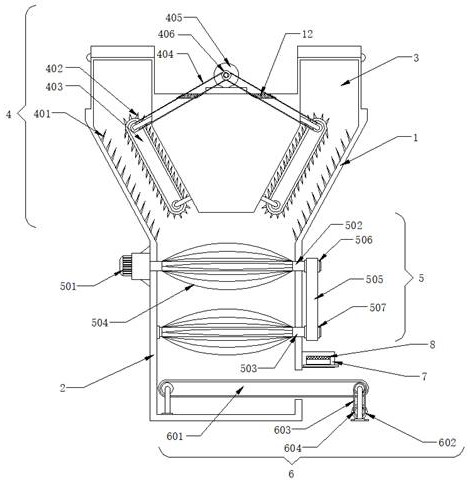

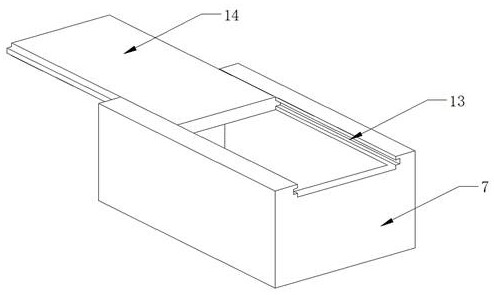

[0026] Such as Figure 1-3 As shown, the present invention provides a cotton blending machine for flax spinning, comprising an upper cotton mixing box 1, a lower cotton mixing box 2 and a feeding cylinder 3, the upper cotton mixing box is arranged on the lower cotton mixing box 2 and communicated with it , both sides of the top of the mixing box 1 are fixed with the feeding cylinder 3 connected with the upper mixing box 1, the inside of the upper mixing box 1 is provided with a cotton loosening device 4, and the inside of the lower mixing box 2 is from top to bottom A cotton mixing device 5 and a transportation device 6 are arranged in sequence. A gap 9 is provided on one side of the lower cotton mixing box 2. The transportation device 6 passes through the gap 9 and extends to the outside of the lower cotton mixing box 2. The outside of the lower cotton mixing box 2 The side is fixedly connected with a collection box 7, the collection box 7 is an open bottom structure, the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com