Production method of combed polyester cotton yarn

A production method and cotton yarn technology, which is applied in the field of spinning and weaving, can solve the problems of high raw material cost of long-staple cotton, and achieve good blending effect, reduced raw material cost, and good hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

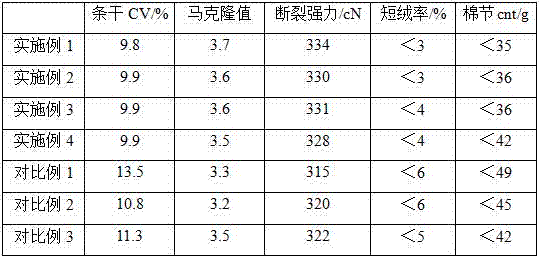

Examples

Embodiment 1

[0032] A kind of production method of combed polyester-cotton yarn, comprises the steps:

[0033] S1. After the polyester staple fiber of 0.8 denier and the soybean fiber of 1.1 denier are respectively through the first cleaning and carding joint operation and the second cleaning and carding joint operation, it is standby;

[0034] S2. After the fine-staple cotton is passed through the third blowing-carding process, pre-merging process, sliver and coiling process, and combing process, it is used for later use;

[0035] S3. spinning the polyester and soybean fibers obtained in step S1 and the combed fine-staple cotton obtained in step S2 into 100 to 120 counts of combed polyester-cotton through a blending process, a roving process and a spinning process; the combed polyester-cotton Contains 60% fine cotton, 33% polyester, 7% soybean fiber.

Embodiment 2

[0037] Same as Example 1, except that the combed polyester contains 60% fine-staple cotton, 32% polyester, and 8% soybean fiber.

Embodiment 3

[0039] Same as Example 1, the difference is that the combed polyester contains 60% fine-staple cotton, 35% polyester, and 5% soybean fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com