Special clear liquid type macroelement water-soluble fertilizer for vegetable and preparation method thereof

A technology of macroelements and chelated trace elements, applied in liquid fertilizers, organic fertilizers, nitrate fertilizers, etc., can solve the problems of high cost, pollute the environment, unsuitable for promotion, etc., and achieve various forms, comprehensive nutrition and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

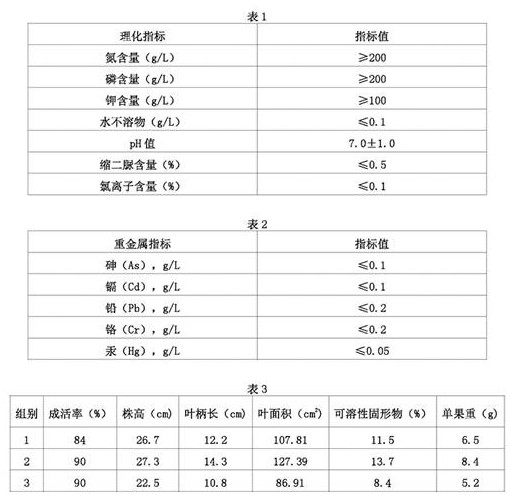

[0024]Example 1: The liquid-type vegetable specialty element water-soluble fertilizer, the raw material includes 25% to 28% urea by weight, 0% to 3% nitrate, 3% to 16% of polyphosphate, 7% of the phosphate Up to 10%, potassium phosphite 3% to 15%, citrate 1% to 3%, chelating trace element package 1.0% to 1.5%, boron 0.3% to 0.5%, ethylene glycol 2.0% to 3.0% and margin For water, it is obtained as follows: First step, sequentially add the required amount of phosphate, ammonium polyphosphate, potassium phosphite, urea and potassium nitrate to stir until it is fully dissolved, until it is fully dissolved, resulting in a mixed material Step 2, sequentially add the desired quantitative elements, boron and citric acid to stir until the mixture is subjected to a mixture of boron and citric acid until the solution is clear, and then the mixture is sequentially added in the mixture. After glycol and margin of water, it is given a large amount of water-soluble fever.

[0025]According to the po...

Embodiment 2

[0032]Example 2: The liquid-type vegetable specialty element water-soluble fertilizer, the raw material includes 25% or 28% of urea, 0% or 3% nitrate, 13% or 16%, phosphate is 7% Or 10%, potassium phosphite 3% to 15%, citric acid 1% or 3%, chelating trace element package 1.0% or 1.5%, boron 0.3% or 0.5%, ethylene glycol 2.5% or 3.0% and margin For water, it is obtained as follows: First step, sequentially add the required amount of phosphate, ammonium polyphosphate, potassium phosphite, urea and potassium nitrate to stir until it is fully dissolved, until it is fully dissolved, resulting in a mixed material Step 2, sequentially add the desired quantitative elements, boron and citric acid to stir until the mixture is subjected to a mixture of boron and citric acid until the solution is clear, and then the mixture is sequentially added in the mixture. After glycol and margin of water, it is given a large amount of water-soluble fever.

Embodiment 3

[0033]Example 3: As an optimization of the above embodiment, the phosphate is one of the potassium hydrogen phosphate, potassium tripolyphosphate and potassium pyrophosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com