Composite adsorption material applied to field of blood purification and preparation method of composite adsorption material

A technology of blood purification and adsorption materials, applied in chemical instruments and methods, blood circulation treatment, alkali metal compounds, etc., can solve the problems of patients with thrombus particles, increase the economic burden of patients, and the small amount of ligand coupling, etc., to achieve Good ball forming, improved safety, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

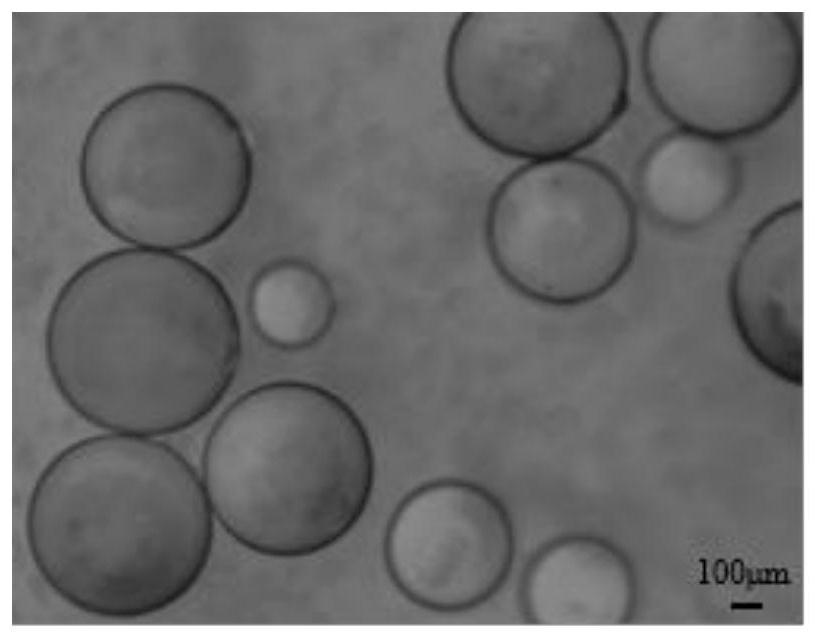

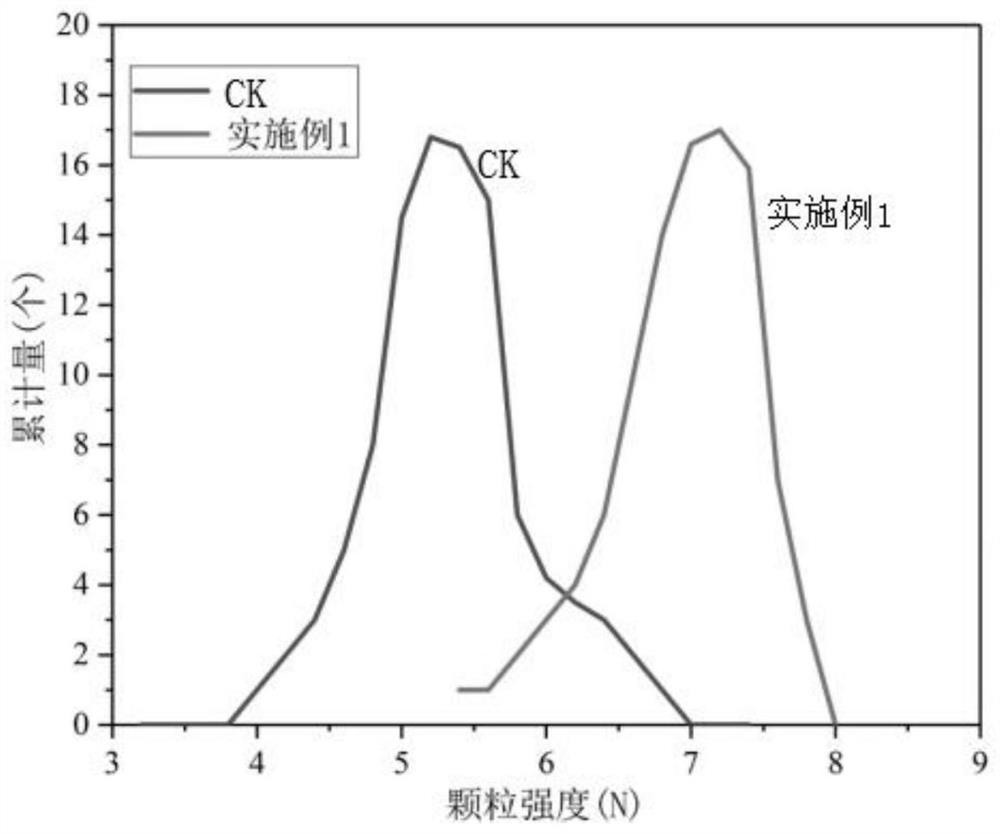

[0038] Example 1 Preparation of the adsorbent of the present invention

[0039] Ethyl orthosilicate, γ-aminopropyl triethoxysilane (KH550), absolute ethanol, hydrochloric acid and deionized water were added to the reaction kettle. In the reaction kettle, ethyl orthosilicate, γ-aminopropyl triethyl The molar ratio of oxysilane, absolute ethanol, hydrochloric acid and deionized water is 1,:2:4.5:0.1:2.5, stir at 70°C for 12h, and then distill under normal pressure to remove the solvent and unreacted monomers, etc. A polysiloxane is obtained. Weigh 1 g of hexadecyl trimethyl ammonium bromide (CTAB) and dissolve it in water, place it in a reaction flask with stirring and heat to 50°C, add 4.2 g of toluene to 35 g of polysiloxane, stir evenly, and stir at 150 rpm. It was added into the reaction flask at a high speed, and then 10 g of ammonia water was added to react for 15 h to obtain silicon-based carrier particles. After filtration, it was fully washed with deionized water and ...

Embodiment 2

[0043] Example 2 Preparation of the adsorbent of the present invention

[0044] Add methyl orthosilicate, γ-aminopropyltriethoxysilane, anhydrous methanol, hydrochloric acid and deionized water into the reaction kettle, and in the reaction kettle, methyl orthosilicate, γ-aminopropyltriethoxysilane , anhydrous methanol, hydrochloric acid and deionized water in a molar ratio of 1:2:4.5:0.1:2.5, stirring at 70 °C for 12 h, and then distilling off the solvent and unreacted monomers under normal pressure to obtain polysiloxane alkyl. Weigh 1 g of polyvinyl alcohol and dissolve it in water, place it in a reaction flask with stirring and heat to 40°C, add 4.2 g of cyclohexane to 35 g of polysiloxane, stir evenly, and add it to the reaction flask at a stirring speed of 150 rpm , and 5 g of ammonia water was added to react for 15 h to obtain silicon-based carrier particles. After filtration, it was fully washed with deionized water and anhydrous methanol, and then dried under vacuum ...

Embodiment 3

[0047] Example 3 Preparation of the adsorbent of the present invention

[0048] Add ethyl orthosilicate, γ-aminopropyl triethoxysilane, absolute ethanol, hydrochloric acid and deionized water into the reaction kettle, and in the reaction kettle, ethyl orthosilicate, γ-aminopropyl triethoxysilane , absolute ethanol, hydrochloric acid and deionized water in a molar ratio of 1:2:4.5:0.1:2.5, stirred at 70 °C for 12 h, and then distilled off the solvent and unreacted monomers under normal pressure to obtain polysiloxane alkyl. Weigh 1 g of Tween 20 and dissolve it in water, place it in a reaction flask with stirring and heat to 60°C, add 4.2 g of toluene to 35 g of polysiloxane and stir evenly, add it to the reaction flask at a stirring speed of 150 rpm, and then add it to the reaction flask. Silicon-based carrier particles were obtained after adding 10 g of ammonia water to react for 15 h. After filtration, it was fully washed with deionized water and absolute ethanol, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com