Method for recovering silver and gold from anode slime containing silver and gold

A technology of anode slime and reaction, applied in the direction of improving process efficiency, etc., can solve the problems of harsh recovery conditions and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

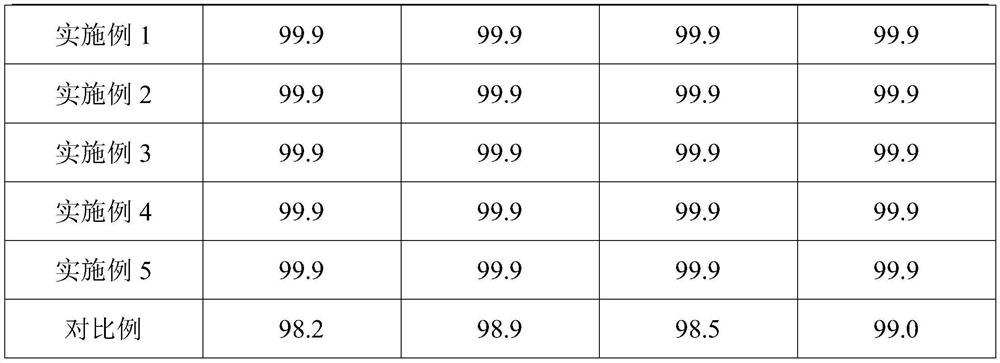

Embodiment 1

[0026] (1) After grinding the anode slime with absolute ethanol, dry it, and slowly add the obtained powder into aqua regia, the mass ratio of aqua regia to anode slime is 1:2, stir and dissolve at 35°C and 1000rpm for 1 hour; finally carry out Filter to obtain filtrate and solid residue;

[0027] (2) Add 0.5g of zirconium chloride and 0.5g of 2-aminoterephthalic acid into 100ml of DMF and stir until the solid dissolves, then add 2ml of acetic acid, ultrasonically treat, and finally heat and stir in an oil bath at 100°C and 1000rpm for reaction After 3h, cool to room temperature after the reaction, and filter the reaction solution, wash and dry the obtained solid to obtain an amino-modified Zr-MOF material with an average particle size of 50±5nm and a specific surface area of 1045.5m 2 / g;

[0028] (3) The filtrate obtained above is added to an adsorption column loaded with an amino-modified Zr-MOF material, and a multi-stage cycle adsorption treatment is carried out until ...

Embodiment 2

[0032] (1) After grinding the anode slime with absolute ethanol, dry it, and slowly add the obtained powder into aqua regia, the mass ratio of aqua regia to anode slime is 1:4, stir and dissolve at 55°C and 1500rpm for 3 hours; finally carry out Filter to obtain filtrate and solid residue;

[0033] (2) Add 1g of zirconium chloride and 0.8g of 2-aminoterephthalic acid into 100ml of DMF and stir until the solid dissolves, then add 5ml of acetic acid, perform ultrasonic treatment, and finally heat and stir in an oil bath at 100°C and 1500rpm to react 3 -7h, cool to room temperature after the reaction, and filter the reaction solution, wash and dry the obtained solid to obtain an amino-modified Zr-MOF material; the average particle size is 50±5nm, and the specific surface area is 1046.3m 2 / g;

[0034] (3) The filtrate obtained above is added to an adsorption column loaded with an amino-modified Zr-MOF material, and multi-stage cyclic adsorption treatment is carried out until no ...

Embodiment 3

[0038] (1) After grinding the anode slime with absolute ethanol, dry it, and slowly add the obtained powder into aqua regia, the mass ratio of aqua regia to anode slime is 1:3, stir and dissolve at 40°C and 1200pm for 2 hours; finally carry out Filter to obtain filtrate and solid residue;

[0039] (2) Add 0.8g of zirconium chloride and 0.6g of 2-aminoterephthalic acid into 100ml of DMF and stir until the solid dissolves, then add 3ml of acetic acid, ultrasonically treat, and finally heat and stir in an oil bath at 100°C and 1500pm for reaction After 5h, cool to room temperature after the reaction, and filter the reaction solution, wash and dry the obtained solid to obtain an amino-modified Zr-MOF material; the average particle size is 50±5nm, and the specific surface area is 1045.8m 2 / g;

[0040] (3) The filtrate obtained above is added to an adsorption column loaded with an amino-modified Zr-MOF material, and multi-stage cyclic adsorption treatment is carried out until no g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com