Textured piezoelectric ceramic laminated driver and preparation method thereof

A technology of piezoelectric ceramics and drivers, which is applied in the field of piezoelectric ceramic devices and can solve problems such as high driving voltage, low piezoelectric performance, and large strain hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

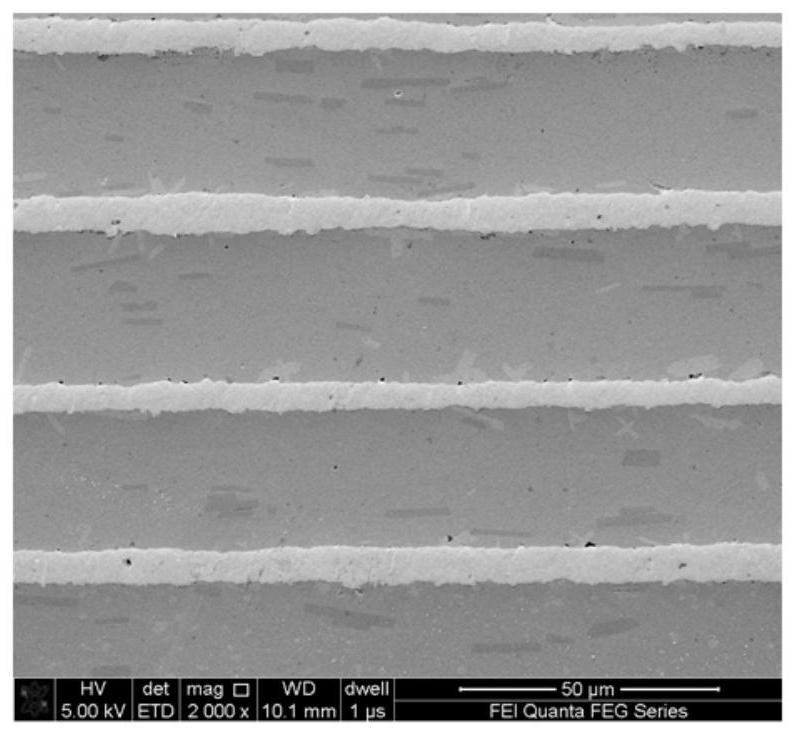

Image

Examples

Embodiment 1

[0058] In Example 1, the lead-based ceramic base powder of PMN-30PT component is selected, and the powder is obtained by two-step solid-phase synthesis, that is, MgO and Nb 2 o 5 Synthesis of MgNb 2 o 6 , then Pb 3 o 4 , MgNb 2 o 6 and TiO 2 After fully mixing, pre-fire at 850°C for 2 hours, and the sintering aid is CuO. In the casting formula: the solvent is a binary azeotropic solvent of butanone and absolute ethanol, the binder is PVB, the dispersant is glycerol trioleate, the plasticizer is polyethylene glycol and dibutyl phthalate, Sintered textured ceramics d 33 It is 790-860pC / N. The specific production steps are as follows:

[0059] Step 1: Weigh the raw materials according to the chemical formula ratio, and obtain PMN-30PT ceramic powder by ball milling, drying, and pre-sintering at 850°C for 2 hours; prepare and wash pure BaTiO by two-step topochemical method 3 (BT) sheet template;

[0060] Step 2: Take 30g of the above-mentioned ceramic matrix powder, mi...

Embodiment 2

[0066] In Example 2, lead-based PZT-15SKN is used as the dielectric material of the textured laminated piezoelectric actuator, and its molecular formula is 0.85Pb (Zr 0.52 Ti 0.48 -0.15Sr(K 0.25 Nb 0.75 )O 3 , the template grain growth technique (TGG) is used in the process to prepare textured piezoelectric ceramics, adding Li 2 CO 3 As a sintering aid, in the casting formula: the solvent is a binary azeotropic solvent of xylene and absolute ethanol, the binder is PVB, the dispersant is phosphate, and the plasticizer is polyethylene glycol and dibutyl phthalate Esters, the highest texture degree of sintered textured ceramics is 97.1%. Specific steps are as follows:

[0067] Step 1: Preparation of fine-grained piezoelectric ceramic matrix by solid-state method: PbO, TiO 2 , SrCO 3 、K 2 CO 3 After ball milling with absolute ethanol for 24 hours, it was dried, and then calcined at 850°C for 4 hours.

[0068] Pure BaTiO was prepared by two-step topological chemistry an...

Embodiment 3

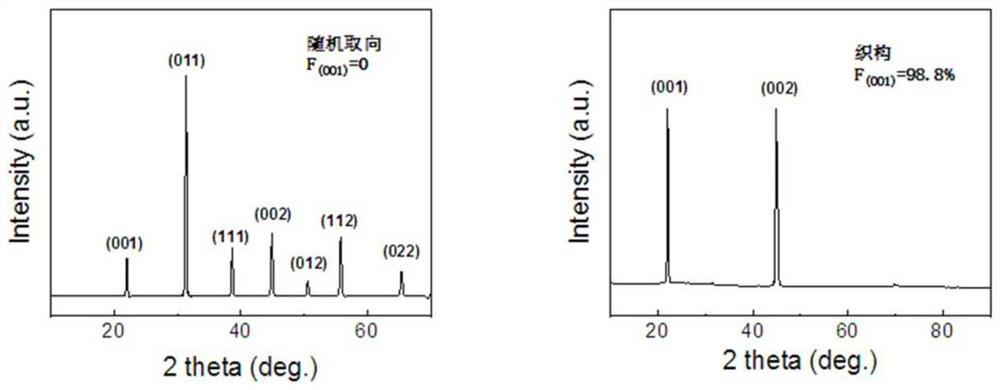

[0075] In Example 3, lead-based 17PIN-38PSN-45PT is used as the dielectric material of the textured laminated piezoelectric driver, and its molecular formula is 0.17Pb(In 1 / 2 Nb 1 / 2 )O 3 -0.38Pb(Sc 1 / 2 Nb 1 / 2 )O 3 -0.45PbTiO 3 In the process, the template grain growth technology (TGG) is used to prepare textured piezoelectric ceramics, and CuO is added as a sintering aid. In the casting formula: the solvent is a binary azeotrope of methyl ethyl ketone and absolute ethanol. The agent is PVB, the dispersant is melted herring oil, the plasticizer is polyalkylene glycol and butyl benzyl phthalate, the highest texture degree of sintered ceramics is 98.8%, and its XRD pattern is as follows: image 3 shown, d 33 It is 1000pC / N. The specific production steps are as follows:

[0076] Step 1: This example mixes In according to the chemical formula ratio 2 o 3 and Nb 2 o 5 、Sc 2 o 3 and Nb 2 o 5 Synthesis of pure-phase InNbO separately by solid-phase synthesis 4 (IN), Sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com