Preparation method of bipolar plate for optimizing drainage capacity of fuel cell

A drainage capacity, fuel cell technology, applied to fuel cell components, fuel cells, circuits, etc., can solve problems such as complex processing technology, inability to meet the different requirements of drainage, and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

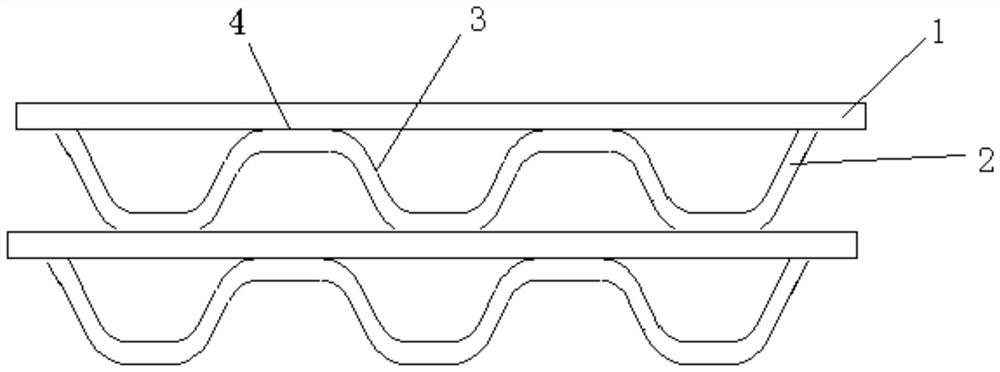

[0020] A method for preparing a bipolar plate that optimizes the drainage capacity of a fuel cell. The bipolar plate is composed of arc grooves and ridges to form a flow channel. The surface of the bipolar plate flow channel is firstly treated to form a hydrophilic layer. The part 3 is subjected to hydrophobic treatment to form a hydrophobic layer, so that the surface of the arc groove part 3 of the bipolar plate is a hydrophobic surface, and the surface of the ridge part 4 is a hydrophilic surface. The method of carrying out the hydrophobic treatment on the arc groove part 3 of the bipolar plate is as follows:

[0021] 1) Combine a bipolar plate 2 with a hydrophilic treatment on the surface of the flow channel and a separator 1 to form a pseudo-galvanic battery. The ridge 4 of the bipolar plate 2 is closely attached to the separator 1, and multiple pieces are assembled in this way The dummy primary cell is assembled into a filled dummy stack, and the separator 1 is a membrane ...

Embodiment 1

[0024] Example 1 is a stainless steel bipolar plate.

[0025] The stainless steel bipolar plate consists of arc grooves and ridges to form a flow channel. The surface of the arc groove part 3 of the stainless steel bipolar plate is a hydrophobic surface, and the surface of the ridge part 4 is a hydrophilic surface.

[0026] The preparation method includes hydrophilic treatment on the surface of the flow channel of the stainless steel bipolar plate and hydrophobic treatment on the arc groove of the bipolar plate. The method of hydrophobic treatment on the arc groove 3 of the bipolar plate is as follows:

[0027] 1) Combine a stainless steel bipolar plate 2 with hydrophilic treatment on the surface of the flow channel and a separator 1 to form a fake primary battery, the ridge 4 of the stainless steel bipolar plate 2 is closely attached to the separator 1, and multiple pieces The pseudo primary cell assembled in this way is assembled into a filled pseudo stack, and the separator...

Embodiment 2

[0030] Embodiment 2 is a graphite bipolar plate, which is also assembled into a filling pseudo-stack with a separator, and the separator 1 is a membrane electrode or a membrane electrode without a catalyst; the hydrophobic agent is a nano-silica superhydrophobic agent. Use the hydrophobic agent to circulate in the hydrogen-oxygen flow field for 5-30 minutes, release the hydrophobic agent from the hydrogen chamber and the air chamber, and then blow the two chambers with compressed air to remove the residual hydrophobic agent; disassemble the filling dummy stack, take out For bipolar plates, dry and cure in an oven at 50-150°C for 10-150 minutes, and the water contact angle at the hydrophobic treatment position can reach 140-150°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com