Preparation method of sintered neodymium-iron-boron magnet with high corrosion resistance and high coercivity

A high coercive force, neodymium iron boron technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

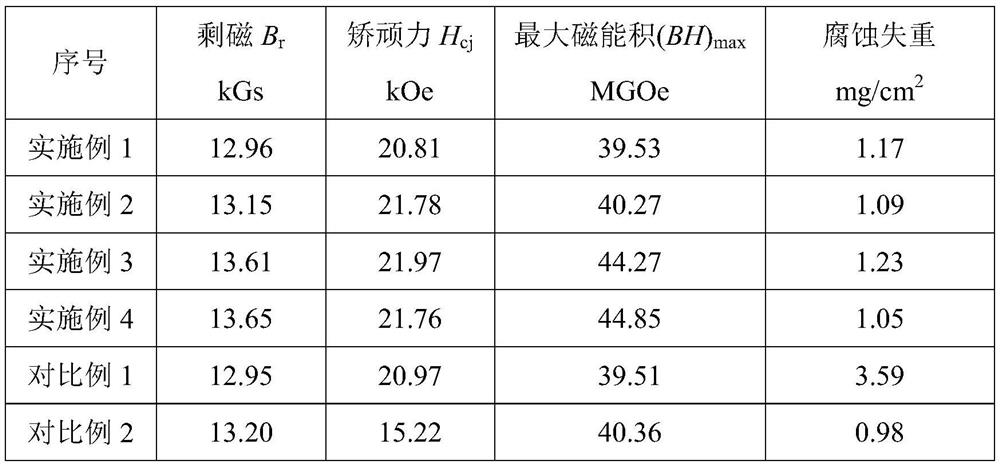

Examples

Embodiment 1

[0027] (1) The average particle size is 2.0μm (La 0.1 Nd 0.9 ) 31 Fe 67.6 B(CoZr) 0.2 The alloy powder and the Al powder with an average particle size of 10 nm were fully mixed according to the ratio of 99.9:0.1, and the mixing time was 2 hours to obtain a mixture.

[0028] (2) Place the mixture in a 1.8T magnetic field to make a green compact through a vibration orientation pressing;

[0029] (3) Carry out high-temperature sintering treatment on the compact, the sintering temperature is 1100°C, and the sintering time is 3h to obtain a sintered NdFeB magnet;

[0030] (4) A layer of Tb is deposited on the surface of the sintered NdFeB magnet by magnetron sputtering, and the grain boundary diffusion treatment is carried out at 700 ° C for 20 hours; followed by two-stage tempering heat treatment, wherein the first-stage tempering process includes: the temperature is 900°C, the time is 6h; the secondary tempering process includes: the temperature is 480°C, and the time is 6h....

Embodiment 2

[0032] (1) The (Ce 0.2 Nd 0.8 ) 33 Fe 61.1 B 0.9 (Co 0.9 Nb 0.1 ) 5 The alloy powder and the Cu powder with an average particle size of 500nm were fully mixed according to 99:1, and the mixing time was 6h to prepare the mixture.

[0033] (2) Place the mixture in a 2.0T magnetic field to form a green compact through two times of vibration orientation pressing;

[0034] (3) Carry out high-temperature sintering treatment to the compact, the sintering temperature is 1000°C, and the sintering time is 10h to obtain a sintered NdFeB magnet;

[0035] (4) A layer of terbium hydride is deposited on the surface of the sintered NdFeB magnet by spraying method, and the grain boundary diffusion treatment is carried out at 750 ° C for 10 h; followed by tempering heat treatment, the first-level tempering process includes: the temperature is 910 ° C, the time is 5h; The secondary tempering process includes: the temperature is 520°C, and the time is 4h. Finally, a sintered NdFeB magnet...

Embodiment 3

[0037] (1) The average particle size is 3.0μm (Pr 0.25 Nd 0.75 ) 30 Fe 66.9 B 1.1 co 2 The alloy powder and the Ga powder with an average particle size of 300nm were thoroughly mixed at a ratio of 98:2, and the mixing time was 10 hours to obtain a mixture.

[0038] (2) The mixture is placed in a 2.2T magnetic field to form a green compact through three times of vibration orientation pressing;

[0039] (3) Carry out high-temperature sintering treatment to the compact, the sintering temperature is 1050 ° C, and the sintering time is 6 hours to obtain a sintered NdFeB magnet;

[0040] (4) A layer of terbium fluoride is deposited on the surface of the sintered NdFeB magnet by electrophoretic deposition method, and the grain boundary diffusion treatment is carried out at 850 ° C for 1 h; followed by tempering heat treatment, the primary tempering process includes: the temperature is 920 ° C, The time is 3h; the secondary tempering process includes: the temperature is 600°C, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com