Spinning Control Method of High Temperature Resistant Polyurethane Elastic Fiber

A polyurethane elasticity and spinning control technology, which is applied in fiber processing, stretch spinning, rayon manufacturing, etc., to achieve the effects of increased orientation and crystallinity, good structural consistency, and improved breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

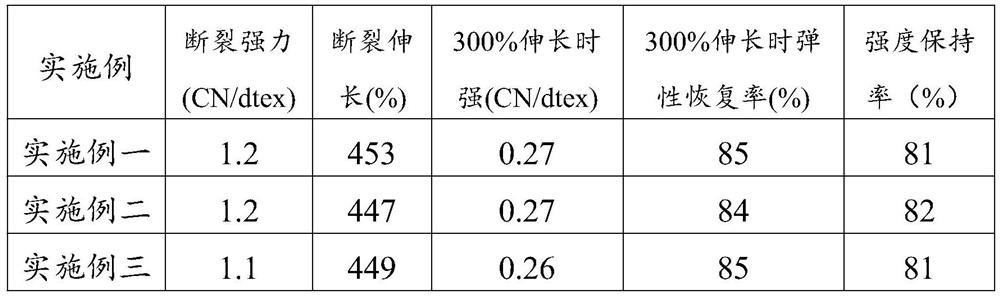

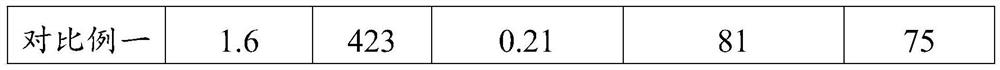

Examples

preparation example Construction

[0037] The preparation method of the high-temperature-resistant polyurethane elastic fiber spinning stock solution in the embodiment of the present invention is according to the patent "a kind of spandex with good heat resistance and stability and its preparation method" (publication number: CN 111101230 A) that the applicant has applied for and disclosed Prepared by the method in, the specific steps are as follows:

[0038](1) Prepolymerization reaction: Mix polytetramethylene ether glycol (molecular weight: 1800) and 4,4'-diphenylmethane diisocyanate, react at 68°C for 120min, and then use N,N-dimethylethylene The amide is used as a solvent to fully dissolve the prepolymer, and the prepolymer solution is obtained after cooling;

[0039] (2) Polymerization reaction: transfer the prepolymer solution to the polymerization reactor, stir evenly, and install a cooling pipe on the outer plate of the polymerization reactor to control the temperature in the polymerization reactor, an...

Embodiment 1

[0048] High temperature resistant polyurethane elastic fiber spinning control method, the specific tunnel system control parameters are as follows:

[0049] The pressure of the delivery pipeline that transports the spinning dope to the spinning assembly is set to 8.0Mpa, the temperature of the delivery pipeline is set to 50°C, the hole of the spinning assembly is a circular cross-section, the cross-sectional diameter is 0.3mm, and the effective length is 1.2mm;

[0050] Set the temperature of the upper part of the corridor from the top of the corridor to 3.6m from the top of the corridor to 166°C, set the pressure of the air inlet at the upper part of the corridor to 850pa, set the pressure of the air outlet at the upper part of the corridor to 225Pa, and set the wind speed of the air inlet at the upper part of the corridor to 0.3m / s;

[0051] Set the temperature in the middle of the corridor from the position 3.6m from the top of the corridor to the position 6m from the top of...

Embodiment 2

[0058] High temperature resistant polyurethane elastic fiber spinning control method, the specific tunnel system control parameters are as follows:

[0059] The pressure of the delivery pipeline that transports the spinning dope to the spinning assembly is set to 8.0Mpa, the temperature of the delivery pipeline is set to 50°C, the hole of the spinning assembly is a circular cross-section, the cross-sectional diameter is 0.3mm, and the effective length is 1.2mm;

[0060] Set the temperature of the upper part of the tunnel from the top of the tunnel to 4m from the top of the tunnel to 171°C, set the pressure of the air inlet of the tunnel to 780pa, set the pressure of the air outlet of the tunnel to 195Pa, and set the wind speed of the air inlet to 0.2m / s;

[0061] Set the temperature in the middle of the corridor from 4m from the top of the corridor to 6.4m from the top of the corridor to 260°C, set the pressure of the air inlet of the corridor to 880pa, set the pressure of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com