Laser engraving preparation method and application of graphene-ceramic composite electrode array

A ceramic composite and electrode array technology, applied in the field of materials, can solve the problems of phenolic substances affecting the environment, difficult processing, unfavorable electrochemical sensor devices, etc., and achieve the effects of simple and environmentally friendly preparation process, easy industrial scale-up, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

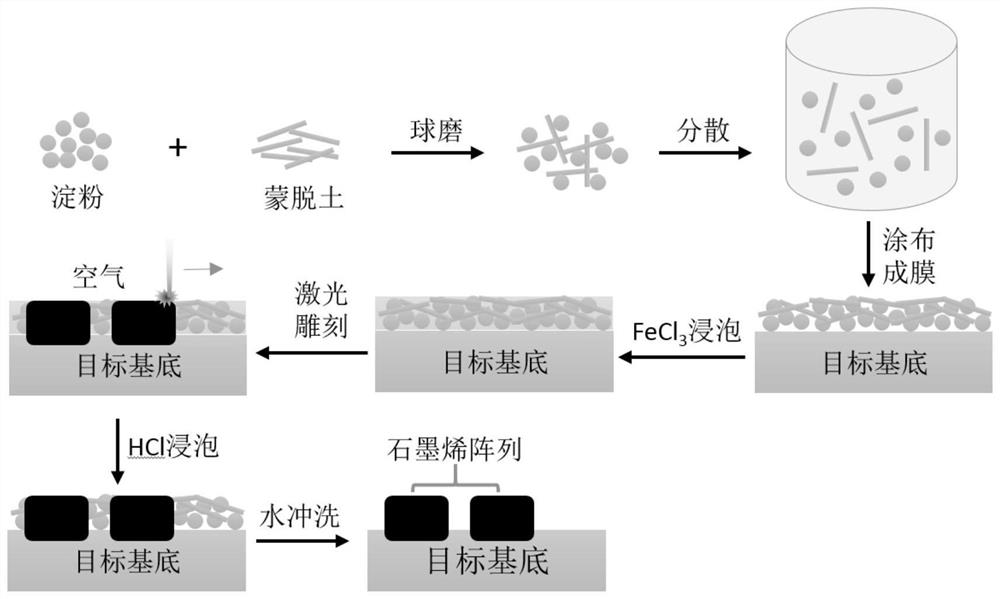

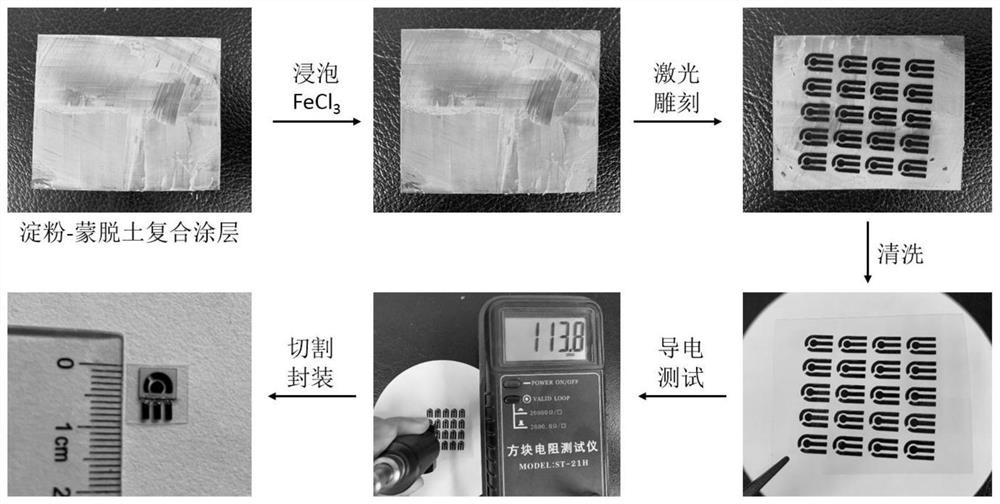

[0038] After mixing 1g of sodium montmorillonite and 2g of corn starch evenly, ball mill for 1-3 hours, add 9-15ml of water to the ball-milled mixture to make a thin paste, and use the method of scraping to form on the surface of the PET plastic sheet substrate. Uniform coating (20-30μm is acceptable), after drying at room temperature, immerse in 2mg / mL (0.5-5mg / mL is acceptable) FeCl 3 in ethanol solution for 1 min, remove it and absorb excess FeCl with filter paper 3 solution, after drying at room temperature, FeCl 3 Doped montmorillonite-starch composite coating.

[0039] Based on the three-electrode array pattern drawn by the computer, using a Diaotu laser engraving machine with a power of 3W and a wavelength of 405nm as the engraving equipment, the prepared FeCl 3The PET plastic sheet substrate covered by the doped montmorillonite-starch composite coating is placed in the engraving area, and engraved at 100% power, 50mm / s (20-100mm / s is acceptable) laser engraving rate ...

Embodiment 2

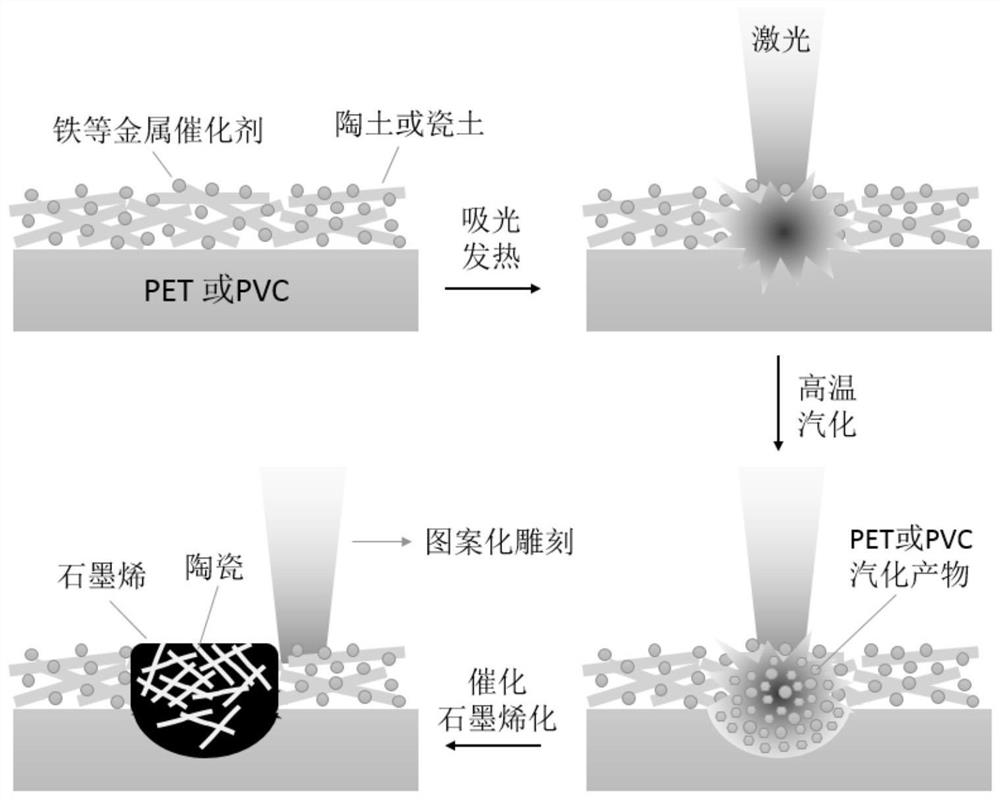

[0043] Reddish-brown refined dry pottery clay and water are mixed into a paste according to the mass ratio of 1:0.5-5, and a certain thickness of coating is formed on the surface of PVC plastic sheet substrate by dip coating method. After drying completely at room temperature or at elevated temperature, use a Wash the bottle with deionized water to remove excess clay on the surface of the coating, and after drying at room temperature or at elevated temperature, a PVC plastic sheet whose surface is evenly covered with an ultra-thin translucent clay coating is obtained, and the coating thickness is about 1 μm.

[0044] Based on the three-electrode array pattern drawn by the computer, a Diaotu laser engraving machine with a power of 3W and a wavelength of 405nm was used as the engraving equipment. / s (20-100mm / s is acceptable) laser engraving speed and engraving under air environment conditions, batch production of PVC-based graphene-ceramic composite three-electrode arrays, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com