Antistatic cloth-based coated abrasive tool and manufacturing method

A coated abrasive and anti-static technology, which is applied in the manufacture of tools, abrasives, conductive adhesives, etc., can solve problems such as potential safety hazards, affecting the surface finish of grinding objects, and sparks caused by static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

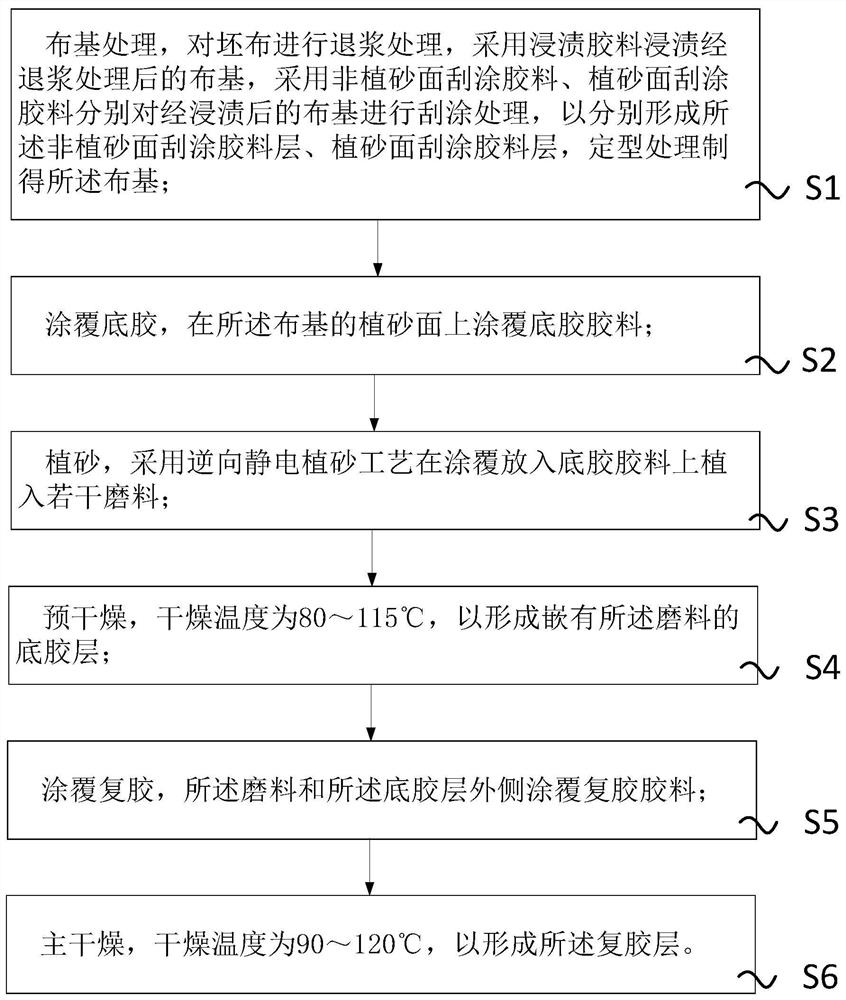

[0107]Method for producing an antistatic cloth base applying a abrasive tool as described above, including the following steps:

[0108](1) Billet fabric with carbon fiber and polyester fiber is used for the preparation of cloth base, the green containing 70 parts by weight of polyester, 30 parts by weight of carbon fiber, yarn 12 × 10 (ie radial 12 yarn, weft 10 yarn ), Density 102 × 42 (ie radial density 102, weft density 42), single weight 330g / m2;

[0109](2) Application of cloth, specifically includes the following steps:

[0110]A. Configure the deraidin, and use a dentist to immerse the gray cloth, 40 ° C clean water cleaning, and iron drying treatment at 130 ° C;

[0111]b, formulated an antistatic impregnation compound, anti-static non-plant surface scraping rubber and antistatic planted sand scraping rubber;

[0112]c, impregnated with the dentinaled rubber, control the impregnation coating of 170 g / m2After immersion, the oven was separated for 2 min, and the drying temperature was 1...

Embodiment 2

[0126]Method for producing an antistatic cloth base applying a abrasive tool as described above, including the following steps:

[0127](1) The billet cloth using carbon fiber and polyester fiber is used for the preparation of a cloth base, the green garbon contains 80 parts by weight of polyester, 20 parts by weight of carbon fiber, yarn branch 12 × 10, density 102 × 42, single weight 330 g / m2;

[0128](2) Application of cloth, specifically includes the following steps:

[0129]A. Configure the deraidin, and use a dentist to immerse the gray cloth, 40 ° C clean water cleaning, and iron drying treatment at 130 ° C;

[0130]b, formulated an antistatic impregnation compound, anti-static non-plant surface scraping rubber and antistatic planted sand scraping rubber;

[0131]c, impregnated with the dental treatment of the dentinaled rubber, control the impregnation coating of 180 g / m2After immersion, the oven is sandwiched for 3 min, and the drying temperature is 90 ° C;

[0132]D. Scraping the non-pl...

Embodiment 3

[0145]Method for producing an antistatic cloth base applying a abrasive tool as described above, including the following steps:

[0146](1) Billet fabric with carbon fiber and polyester fiber is used for the preparation of cloth base, the green contains 75 parts by weight of polyester, 25 parts by weight of carbon fiber, yarn, 即 radial 12 yarn, latitude 10 yarn ), Density 102 × 42 (ie radial density 102, weft density 42), single weight 330g / m2;

[0147](2) Application of cloth, specifically includes the following steps:

[0148]A. Configure the deraidin, and use a dentist to immerse the gray cloth, 40 ° C clean water cleaning, and iron drying treatment at 130 ° C;

[0149]b, formulated an antistatic impregnation compound, anti-static non-plant surface scraping rubber and antistatic planted sand scraping rubber;

[0150]C. Using the impregnated rubber to impregnate the released cloth, control the impregnation coating is 175 g / m.2After immersion, the oven is sandwiched for 2.5 min, and the dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com