YBCO high-temperature superconductive film band connection technology and special-purpose auxiliary clamp thereof

A technology for high-temperature superconducting thin films and superconducting strips, which is applied in the fields of welding connection methods and auxiliary connection tools for high-temperature superconducting thin film strips, superconducting material connection methods and auxiliary connection tools, and can solve problems that affect the efficiency of the connection process. Quality, increased connection time and other issues, to achieve the effect of fast connection process operation, good mechanical strength, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this example, see Figure 1~Figure 6 , fast and efficient connection of YBCO high temperature superconducting thin film tape process, the specific process steps are:

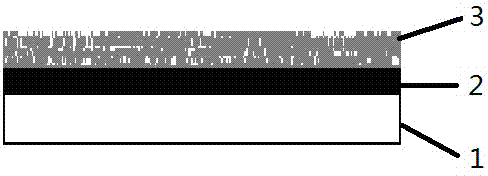

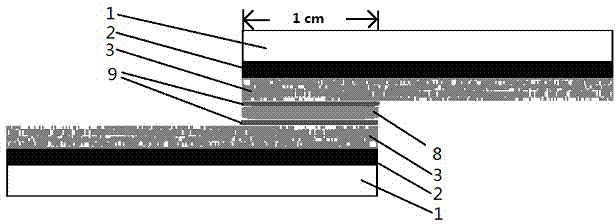

[0035] Step 1: Distinguish the superconducting surface and the basal surface of the strip according to the surface morphology of the YBCO high temperature superconducting thin film strip to be connected, such as figure 1 As shown, the judgment method is: if only one side is coated with silver protective layer 3, then this surface is YBCO superconducting layer 2, and the other side of YBCO superconducting layer 2 is the buffer layer and base layer 1; if both sides are coated with If there is a silver protective layer 3, use an electric soldering iron to remove the silver layer on the surface. The shiny black side is the YBCO superconducting layer 2; One side is the YBCO superconducting layer 2, and the outwardly curved side is the buffer layer and the base layer 1;

[0036] Step 2: Apply flux to the s...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, especially in that:

[0044] In this example, see Image 6 , fast and efficient connection of YBCO high temperature superconducting thin film tape process, the specific process steps are:

[0045] Step 1: This step is the same as Embodiment 1;

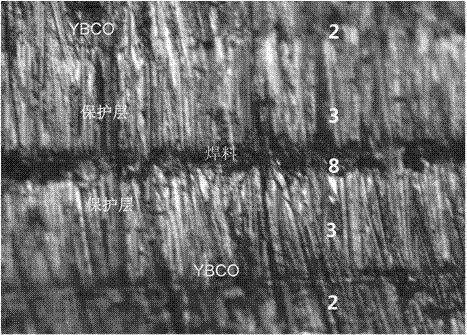

[0046] Step 2: Apply flux to the superconducting surface side of the two strips respectively. Under the temperature condition of 150°C, apply the rosin flux 9 evenly on the superconducting surface side of the two strips with an electric soldering iron, according to The actual overlapping area determines that the coating length is 3cm; then, place a solder 8 of Sn43Bi57 with a melting point of 138°C on the rosin-coated part of one of the strips, and the two ends of the solder 8 placed along the extending direction of the strip exceed the coated rosin. 0.5cm at both ends of the applied flux 9, and then place another strip with the rosin-coated side down on the solder 8, so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com