Preparation method of superhard boron carbide ceramic reinforced iron-based alloy composite wear-resistant coating

A boron carbide ceramic and iron-based alloy technology, applied in the field of materials, can solve the problems of low bonding strength and large residual stress, and achieve the effects of good self-lubrication, low cost, excellent anti-cutting and anti-adhesive wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

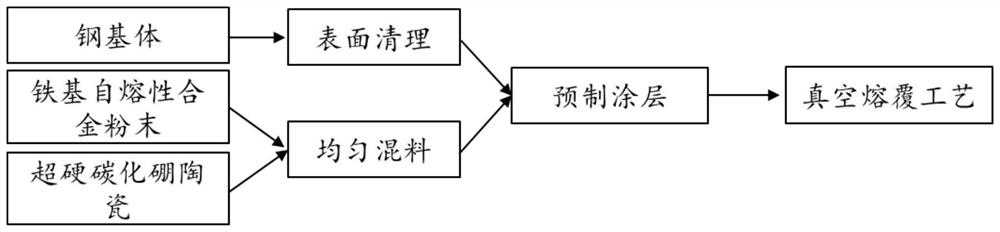

[0044] Process such as figure 1 shown;

[0045] Prepare boron carbide ceramic particles and iron-based self-fluxing alloy powder as raw materials; the particle size of boron carbide ceramic particles is 10-40 μm, and the particle size of iron-based alloy powder is 40-100 μm; the iron-based self-fluxing alloy is FeCrBSi (Fe60) molten alloy;

[0046] Prepare the 45# steel matrix that has been surface treated to form the surface to be clad, with a size of 60mm×60mm×10mm;

[0047] Put boron carbide ceramic particles and iron-based alloy powder into a ball mill for dry ball milling and mixing. The ball-to-material ratio during ball milling and mixing is 2, the ball milling mixing time is 6 hours, and the ball milling speed is 300rpm to obtain a mixed powder; the boron carbide ceramic particles are mixed during ball milling. The mass accounts for 10% of the total mass of boron carbide ceramic particles and iron-based alloy powder;

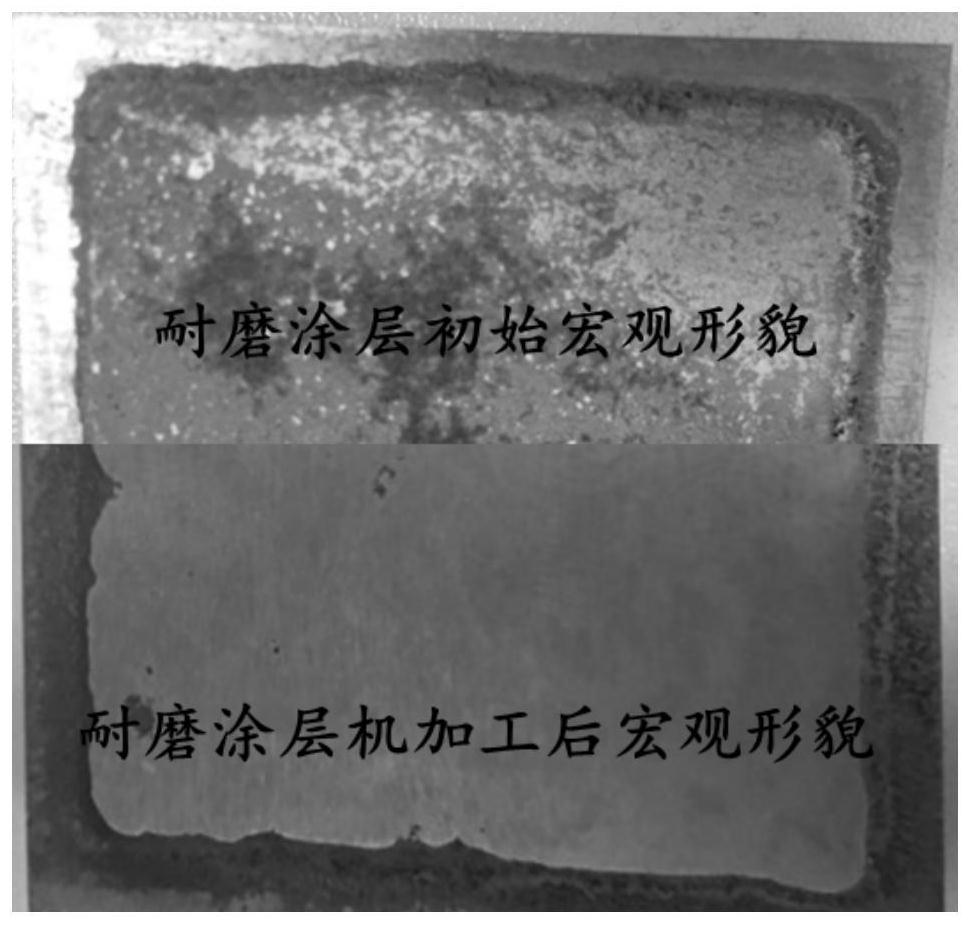

[0048] Add a binder to the mixed powder and sti...

Embodiment 2

[0054] Method is with embodiment 1, and difference is:

[0055] (1) The iron-based self-fluxing alloy is a Fe-Cr-C alloy;

[0056] (2) The substrate is 304 stainless steel substrate, the size

[0057] (3) The ball-to-material ratio during ball milling is 3, the time is 3h, and the rotating speed is 500rpm; the quality of boron carbide ceramic particles accounts for 20% of the total mass of boron carbide ceramic particles and iron-based alloy powder;

[0058] (4) The thickness of the prefabricated coating is 2 mm; the binder is absolute ethanol;

[0059] (5) During vacuum cladding, first raise the temperature to 400°C and keep it warm for 30 minutes; then raise the temperature to the melting point of iron-based alloy powder and keep it warm for 50 minutes;

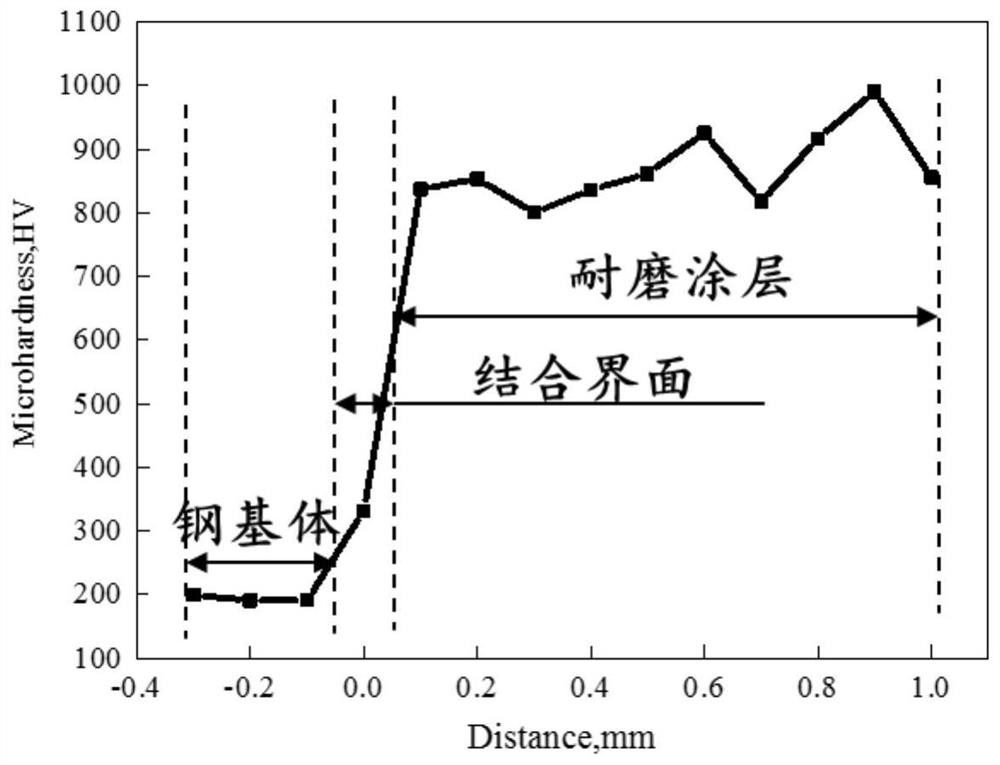

[0060] The microhardness of the iron-based alloy composite wear-resistant coating reinforced by boron carbide ceramic particles is 500-1300HV.

Embodiment 3

[0062] Method is with embodiment 1, and difference is:

[0063] (1) The ball-to-material ratio during ball milling is 2.5, the time is 4h, and the rotating speed is 400rpm; the quality of boron carbide ceramic particles accounts for 5% of the total mass of boron carbide ceramic particles and iron-based alloy powder;

[0064] (2) The thickness of the prefabricated coating is 3mm; the binder is water glass;

[0065] (3) During vacuum cladding, first raise the temperature to 350°C and keep it warm for 40 minutes; then raise the temperature to the melting point of iron-based alloy powder and keep it warm for 40 minutes;

[0066] The microhardness of the iron-based alloy composite wear-resistant coating reinforced by boron carbide ceramic particles is 500-1300HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com