Permeation-resistant three-layer heat exchange tube and preparation method thereof

A heat exchange tube and permeation-resistant technology, which is applied in the direction of hoses, pipes, mechanical equipment, etc., can solve the problems of cooling pipe coolant leakage, affecting cooling effect, poor hydrolysis resistance, etc., to increase vehicle loss and not easy Good effect of peeling and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

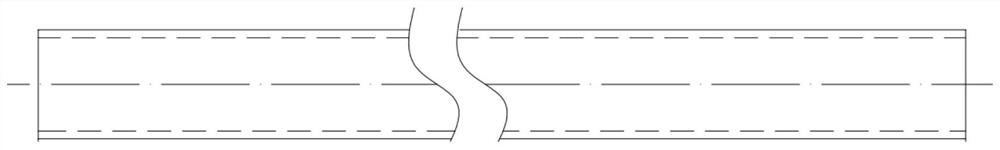

[0035] The permeation-resistant heat exchange tube of the present invention can be made into a light tube, and the light tube includes an inner layer of PP, an adhesive layer and an outer layer of PA12. The preparation method is as follows:

[0036] Step 1. Put the materials of the inner layer, adhesive layer and outer layer into the multi-composite extruder to extrude the three-layer tubular structure; set the extrusion temperature of the inner layer to 240°C, and the pressure of the extrusion material to 170bar; the adhesive layer The extrusion temperature of the outer layer is 240°C, and the extrusion liquid pressure is 120bar; the extrusion temperature of the outer layer is 240°C, and the extrusion liquid pressure is 170bar. When extruding, control the thickness of the inner layer to be min (minimum) 0.5mm, the thickness of the adhesive layer to be min0.1, the thickness of the outer layer to be min0.75mm, and the thickness of the pipe wall to be 1.5±0.15mm.

[0037] Step ...

Embodiment 2

[0041] The permeation-resistant heat exchange tube of the present invention can be made into a light tube, and the light tube includes an inner layer of PP, an adhesive layer and an outer layer of PA12. The preparation method is as follows:

[0042] Step 1. Put the materials of the inner layer, adhesive layer and outer layer into the multi-composite extruder to extrude the three-layer tubular structure; set the extrusion temperature of the inner layer to 245°C, and the pressure of the extrusion material to 160bar; the adhesive layer The extrusion temperature is 245°C, and the extrusion liquid pressure is 100bar; the extrusion temperature of the outer layer is 245°C, and the extrusion liquid pressure is 155bar. Control the thickness of its inner layer, adhesive layer, outer layer and whole tube wall during extrusion to be the same as in Example 1.

[0043] Steps 2, 3 and 4 are the same as in Example 1.

Embodiment 3

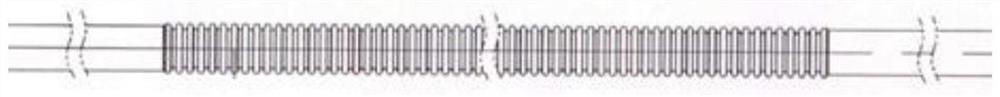

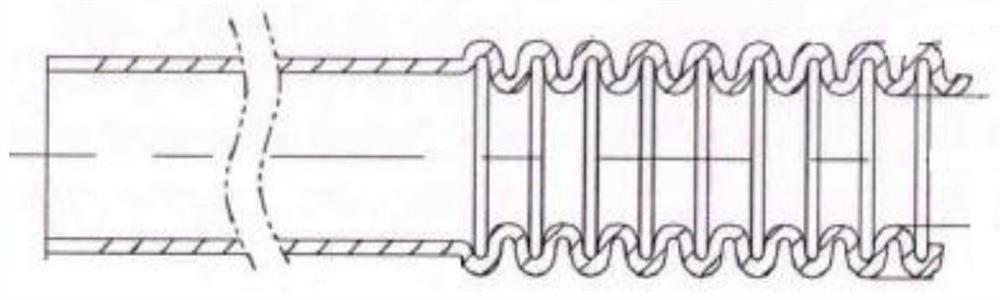

[0045] The permeation-resistant heat exchange tube of the present invention can be made into a corrugated tube, and the corrugated tube also includes a PP inner layer, an adhesive layer and a PA12 outer layer. The structure of the bellows is as Figure 2-3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com