High-performance seawater-resistant antifouling liquid coating for marine equipment engineering

A technology of marine equipment and liquid coatings, applied in antifouling/underwater coatings, epoxy resin coatings, coatings, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

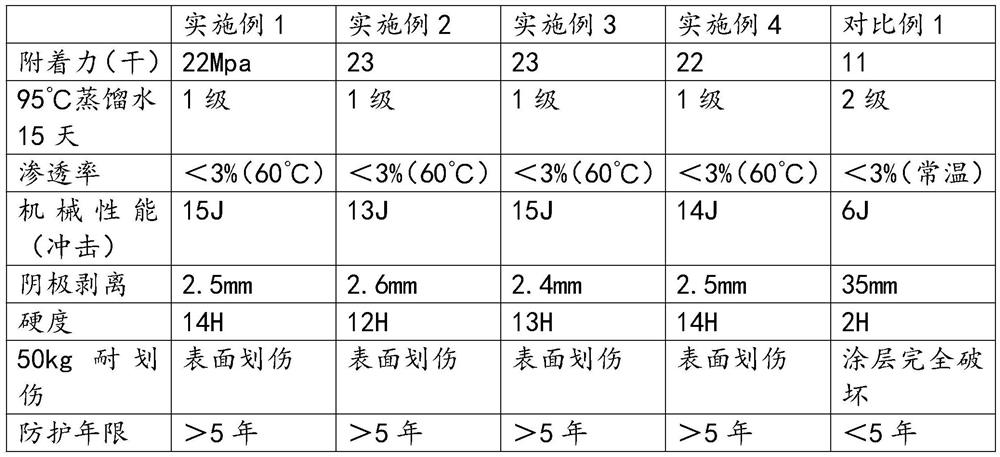

Examples

Embodiment 1

[0022] A high-performance seawater anti-fouling liquid coating for marine equipment engineering, including A component and B component, the A component includes the following raw materials by weight: 55 parts of E51 epoxy resin, 5 parts of composite filler, 15 parts calcium carbonate, 10 parts barium sulfate;

[0023] Composite fillers are made by the following steps:

[0024] Step S1: Add anhydrous citric acid into deionized water, stir at a constant speed for 10 minutes, then slowly add ethylenediamine dropwise, stir magnetically for 30 minutes after complete addition, then transfer to a polytetrafluoroethylene reactor, and react at 200°C for 6 hours to prepare To obtain the reaction solution, add dropwise 10% sodium hydroxide aqueous solution to the reaction solution to adjust the pH until the system is neutral, centrifuge, collect the supernatant and dialyze for 24 hours to obtain solution a, control anhydrous citric acid, ethylenediamine The dosage ratio with deionized w...

Embodiment 2

[0032] A high-performance seawater anti-fouling liquid coating for marine equipment engineering, including A component and B component, the A component includes the following raw materials by weight: 60 parts of E51 epoxy resin, 6 parts of composite filler, 16 parts calcium carbonate, 15 parts barium sulfate;

[0033] Composite fillers are made by the following steps:

[0034] Step S1: Add anhydrous citric acid into deionized water, stir at a constant speed for 10 minutes, then slowly add ethylenediamine dropwise, stir magnetically for 30 minutes after complete addition, then transfer to a polytetrafluoroethylene reactor, and react at 200°C for 6 hours to prepare To obtain the reaction solution, add dropwise 10% sodium hydroxide aqueous solution to the reaction solution to adjust the pH until the system is neutral, centrifuge, collect the supernatant and dialyze for 24 hours to obtain solution a, control anhydrous citric acid, ethylenediamine The dosage ratio with deionized w...

Embodiment 3

[0042]A high-performance seawater anti-fouling liquid coating for marine equipment engineering, including A component and B component, the A component includes the following raw materials by weight: 65 parts of E51 epoxy resin, 8 parts of composite filler, 18 parts calcium carbonate, 18 parts barium sulfate;

[0043] Composite fillers are made by the following steps:

[0044] Step S1: Add anhydrous citric acid into deionized water, stir at a constant speed for 10 minutes, then slowly add ethylenediamine dropwise, stir magnetically for 30 minutes after complete addition, then transfer to a polytetrafluoroethylene reactor, and react at 200°C for 6 hours to prepare To obtain the reaction solution, add dropwise 10% sodium hydroxide aqueous solution to the reaction solution to adjust the pH until the system is neutral, centrifuge, collect the supernatant and dialyze for 24 hours to obtain solution a, control anhydrous citric acid, ethylenediamine The dosage ratio with deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com