Reinforced bar and manufacturing method and device thereof

A technology for manufacturing devices and threaded steel, which is applied in the field of threaded steel production equipment, can solve the problems of poor adaptability and inconvenient recycling of coolant, and achieve the effects of strong adaptability, convenient loading and unloading of collection boxes, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

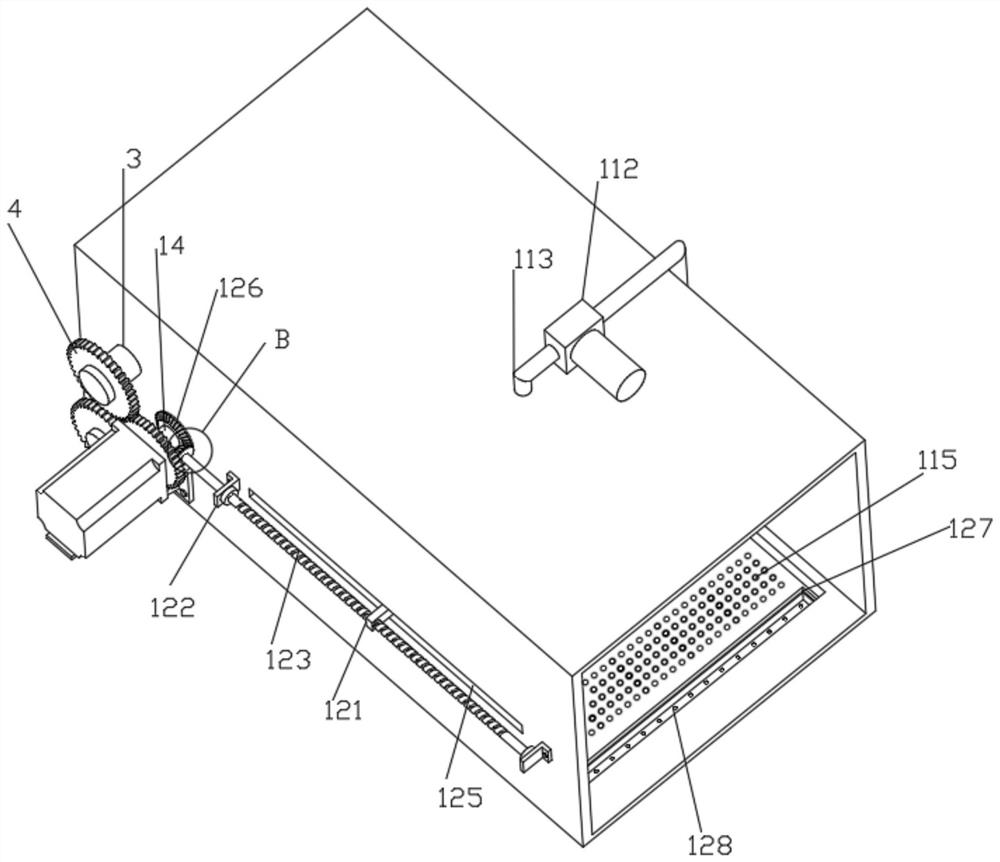

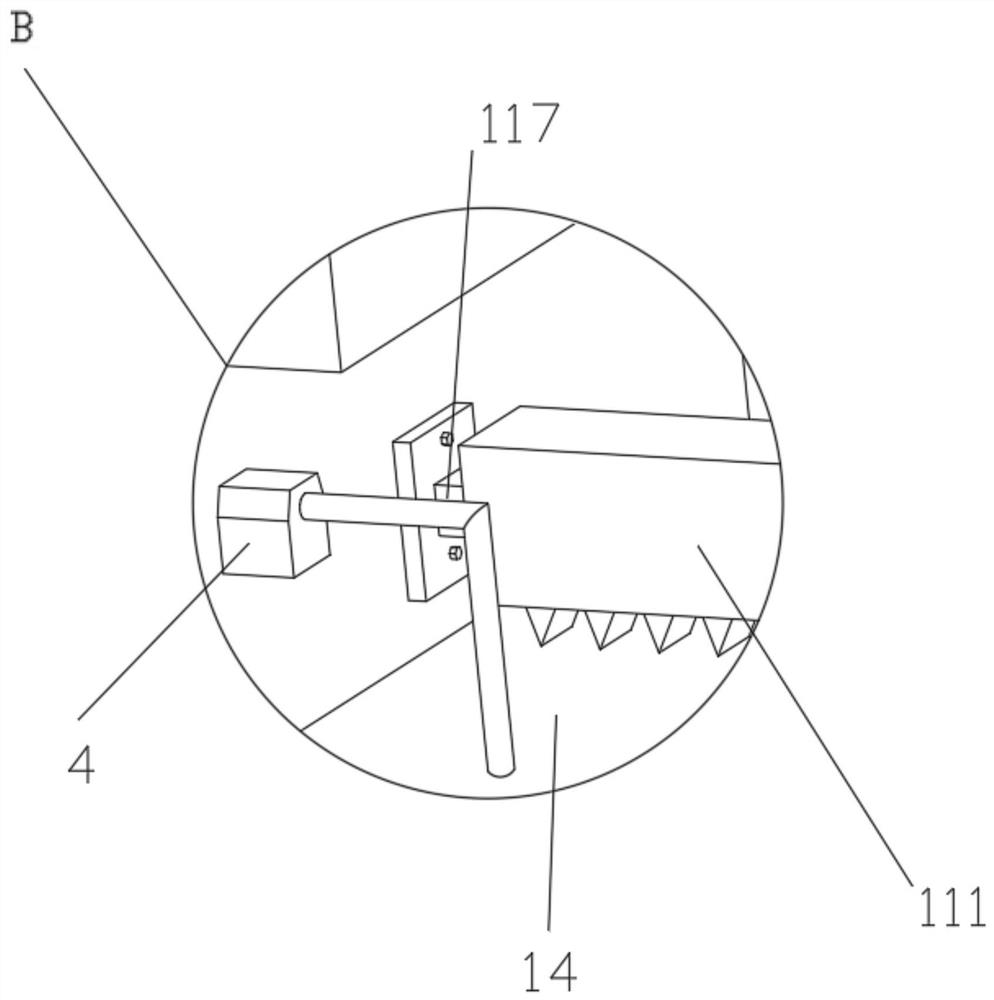

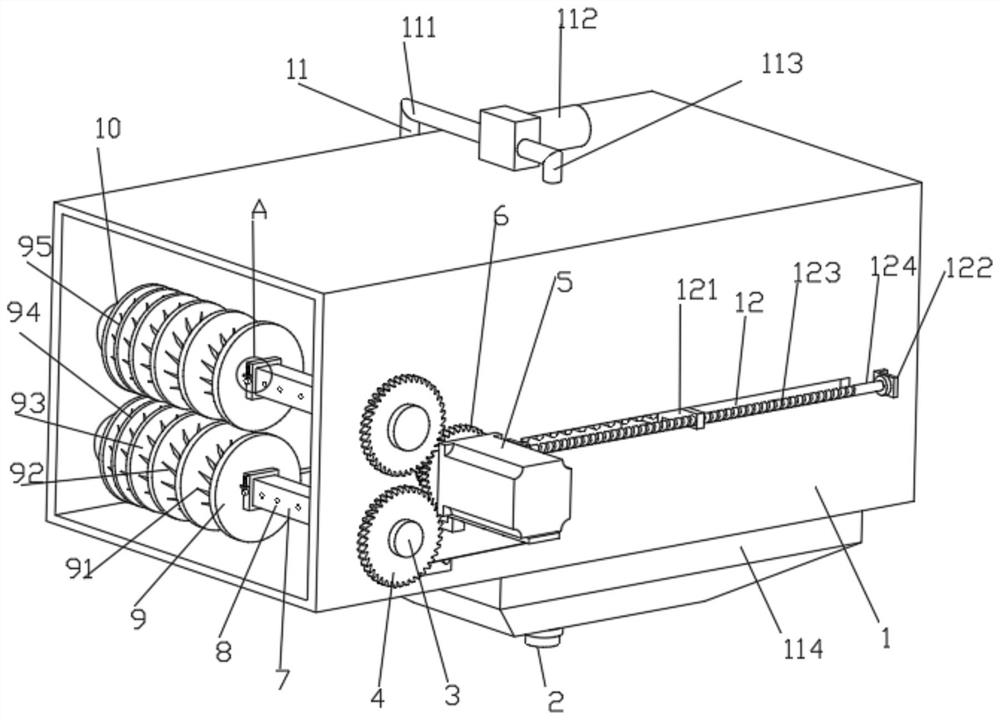

[0042] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 9 show a kind of rebar manufacturing device, including a box body 1, and the left end of the box body 1 is provided with a driving structure for driving the rebar, and the driving structure includes a rotating shaft 3, a first tooth Ring 4, drive motor 5, second ring gear 6, square plate 7, cold roll 9, bearing 10 and rotating shaft 14, four sets of identical rotating shafts 3 are fixedly connected symmetrically to the inner wall of the box body 1, and the rotating shafts 3 are fixedly connected There is a square plate 7, and the cold roll 9 is fitted and slidably connected with the square plate 7 by opening a sliding hole. The output end of the driving motor 5 is fixedly connected with a rotating shaft 14, and the rotating shaft 14 is fixedly installed in the straight hole of the first bevel gear 126 to rotate. The shaft 14 is fixedly connected with the second ring gear 6, and the left end of the second ring gear 6 is symmetri...

Embodiment 2

[0045] Embodiment 2 is a further improvement to Embodiment 1.

[0046] Such as figure 1 , 3 , 8, and 10, the box body 1 is connected with a slag removal structure 12 for removing impurities on the surface of the filter plate 115, and the slag removal structure 12 includes an L-shaped slide plate 121, a connecting plate 122, a reciprocating thread groove 123, a rotating rod 124, and a sliding groove 125, the first bevel gear 126, the mounting groove 127, the collection box 128, the scraper 129 and the second bevel gear 1210, the side wall of the box body 1 is provided with a sliding groove 125, and the connecting plate 122 is rotatably connected by a fixed bearing. Rotating rod 124, the front end of rotating rod 124 is fixedly connected with the second bevel gear 1210, the second bevel gear 1210 is meshed and connected with the first bevel gear 126, the rotating shaft 14 is fixedly installed in the straight hole of the first bevel gear 126, and the rotating rod 124 A reciproc...

Embodiment 3

[0048] A threaded steel, consisting of the following raw materials in parts by weight: 750-1150 parts by weight of pig iron, 12-18 parts by mass of ferrosilicon, 6.3-8 parts by mass of high-carbon ferromanganese alloy, 0.8-8 parts by mass of high-carbon ferrochrome, molybdenum 1.5-6.8 parts by mass of iron alloy, 59-82 parts by mass of copper-titanium alloy, 3-5 parts by mass of nickel-iron alloy, 1-5 parts by mass of ferro-titanium, 22.5-31.5 parts by mass of ferrosilicon nitride and 2.3-4.5 parts by mass of graphene powder , by compounding C, Mn, Ni, P, Ti, graphene and Fe into the alloy, the strength of rebar can be effectively improved without affecting the strength of rebar, and it also has strong corrosion resistance .

[0049] During use, a kind of manufacturing method of rebar device manufacturing method is as follows:

[0050] Step 1: Select one of the first cold-rolled groove 91, the second cold-rolled groove 92, the third cold-rolled groove 93, the fourth cold-roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com