Method for detecting content of water-soluble calcium in dried oysters

A water-soluble calcium and detection method technology, which is applied in the field of inspection, can solve the problems of difficulty in unifying the detection accuracy of calcium ions, difficulty in meeting practical requirements, and large loss of raw materials, so as to avoid loss of activity, good development prospects, and gentle and fast process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

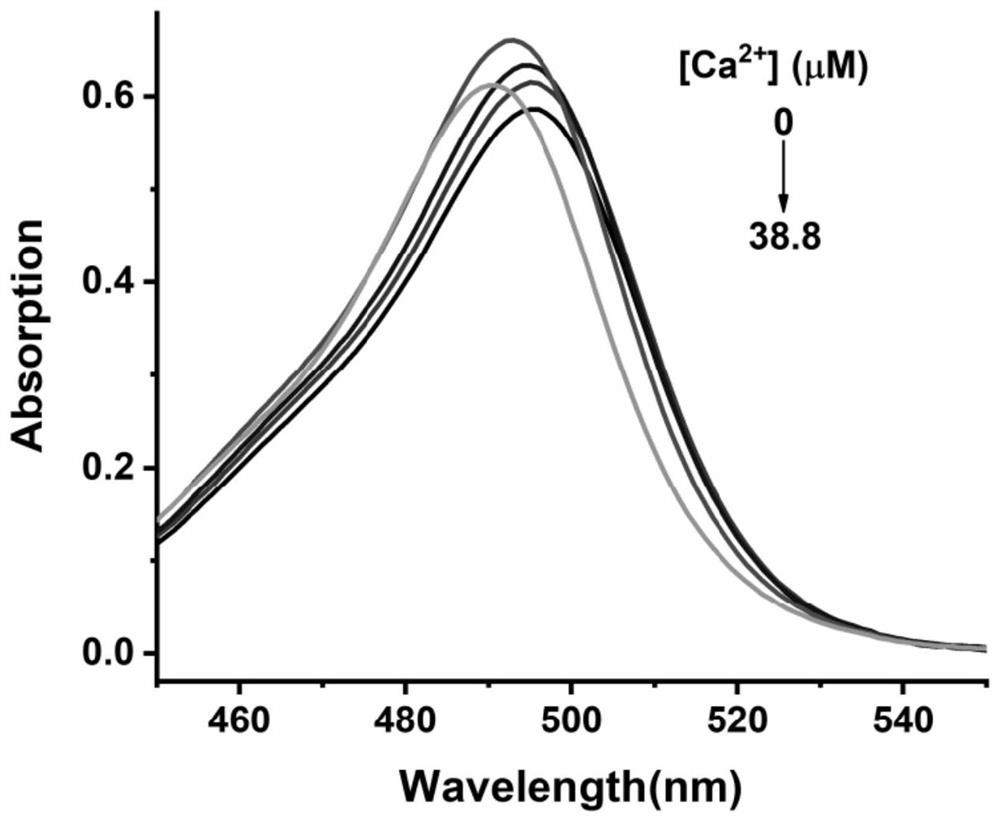

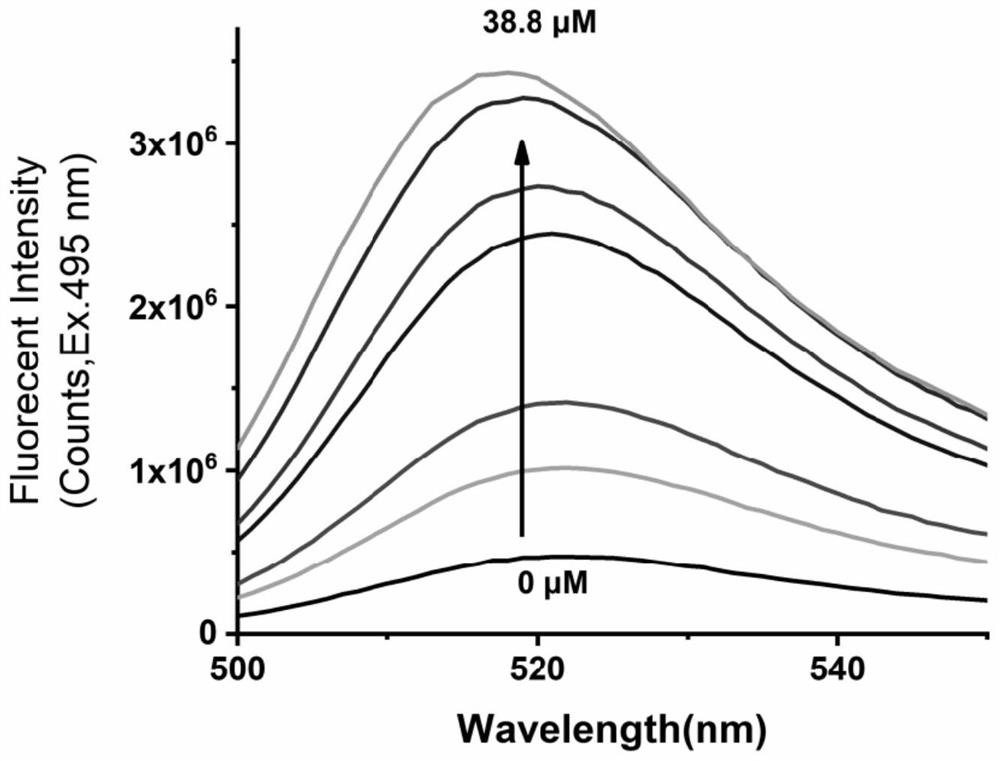

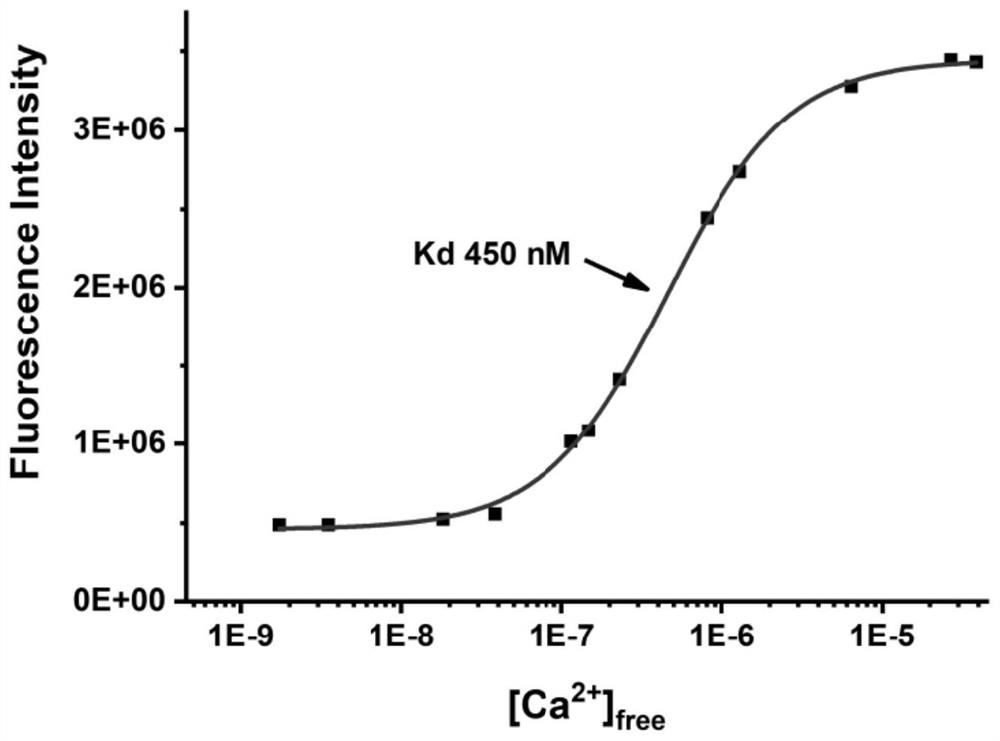

[0042] Preparation of fluorescent probe standard curve

[0043] 1. Preparation of medicines

[0044] (1) 1M 3-morpholine propanesulfonic acid (MOPS) buffer solution: Weigh 20.926g MOPS, add 80mL deionized water to dissolve, adjust the pH value of the solution to 12 with 2M NaOH, and finally add deionized water to dilute to 100 mL, you can get 1M MOPSBuffer (pH=12) buffer.

[0045] (2) 10 mM calcein fluorescent probe: Weigh 0.006205 g of calcein trisodium salt and dissolve it in 1 mL of dimethyl sulfoxide (DMSO).

[0046] (3) 0.1M nitrilotriacetic acid (NTA) solution: Weigh 1.9114g nitrilotriacetic acid (NTA) and dissolve it in 100mL deionized water.

[0047] (4) 0.1M CaCl 2 Solution: Weigh 1.1098g of calcium chloride and dissolve it in 100mL of distilled water. 2. Ca with different concentration gradients 2+ Preparation of the buffer system:

[0048] Take 0.1M CaCl 2Solution 0μL, 50μL, 100μL, 500μL, 1.25mL, 1.5mL, 2.0mL, 2.5mL, 3.5mL, 4.0mL, 4.5mL, 4.75mL, 4.95mL, 4.975...

Embodiment 2

[0070] A method for detecting water-soluble calcium content in dried oysters, comprising the steps of:

[0071] A1. Sample pretreatment: Cut the dried oysters into 2-3 mm long pieces for subsequent grinding; put the cut dried oysters into an oven, adjust the temperature of the oven to 60°C, and dry for 2 hours until the surface is crisp; Put the dried sample into an ultra-centrifugal grinder for crushing, and then use a 100-mesh sieve ring to grind repeatedly until the powder is uniform and has no obvious large particles;

[0072] A2. Microwave-ultrasonic collaborative extraction: take 10g of ground dried oyster powder, add deionized water according to the ratio of solid to liquid ratio of 1:3 for mixing, put it into the extraction instrument, and perform microwave-ultrasonic collaborative extraction to obtain the extract . The microwave power is 300W, the ultrasonic power is 1500W, the extraction temperature is 50°C, and the ultrasonic treatment is continued for 5 minutes. ...

Embodiment 3

[0075] A method for detecting water-soluble calcium content in dried oysters, comprising the steps of:

[0076] A1. Sample pretreatment: Cut the dried oysters into 2-3 mm long pieces for subsequent grinding; put the cut dried oysters into an oven, adjust the temperature of the oven to 60°C, and dry for 3 hours until the surface is crisp; Put the dried sample into an ultra-centrifugal grinder for crushing, and then use a 100-mesh sieve ring to grind repeatedly until the powder is uniform and has no obvious large particles;

[0077] A2. Microwave-ultrasonic collaborative extraction: Take 10g of ground dried oyster powder, add deionized water according to the ratio of solid to liquid ratio of 1:6 for mixing, put it into the extraction instrument, and perform microwave-ultrasonic collaborative extraction to obtain the extract . The microwave power is 300W, the ultrasonic power is 1500W, the extraction temperature is 70°C, and the ultrasonic treatment is continued for 5 minutes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com