Acrylic acid flexible anticorrosive primer and preparation method thereof

An acrylic flexible, anti-corrosion primer technology, applied in the coating field, can solve problems such as failure to meet the requirements of large deformation conditions, elastic coating detachment, cracking of the primer coating, etc., to ensure the feasibility of the test and the compactness of the coating film , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of acrylic flexible anticorrosion primer, is prepared by following method:

[0037] Mix 50 parts of butyl acetate, 30 parts of xylene, 10 parts of mixed dibasic acid ester, and 10 parts of propylene glycol methyl ether acetate to obtain a diluent.

[0038] 45g of homemade flexible acrylic resin with a solid content greater than 45%, 0.5g of dispersant BYK161, 15g of titanium dioxide, 5g of zinc yellow, 8g of talc powder, 4g of zinc phosphate, 1.5g of mica powder, 1.5g of light calcium, 0.2g of bentonite, Add 8.5g of diluent into the stirring container and stir in sequence, then grind until the particle size is below 35μm, add 0.2g of leveling agent BYK306, 0.3g of adhesion promoter EDL-6026F, 0.3g of UV absorber Tinuvin 1130 and 10g of diluent to adjust the solid The content is more than 55% to obtain the first component.

[0039] Where: Homemade flexible acrylic

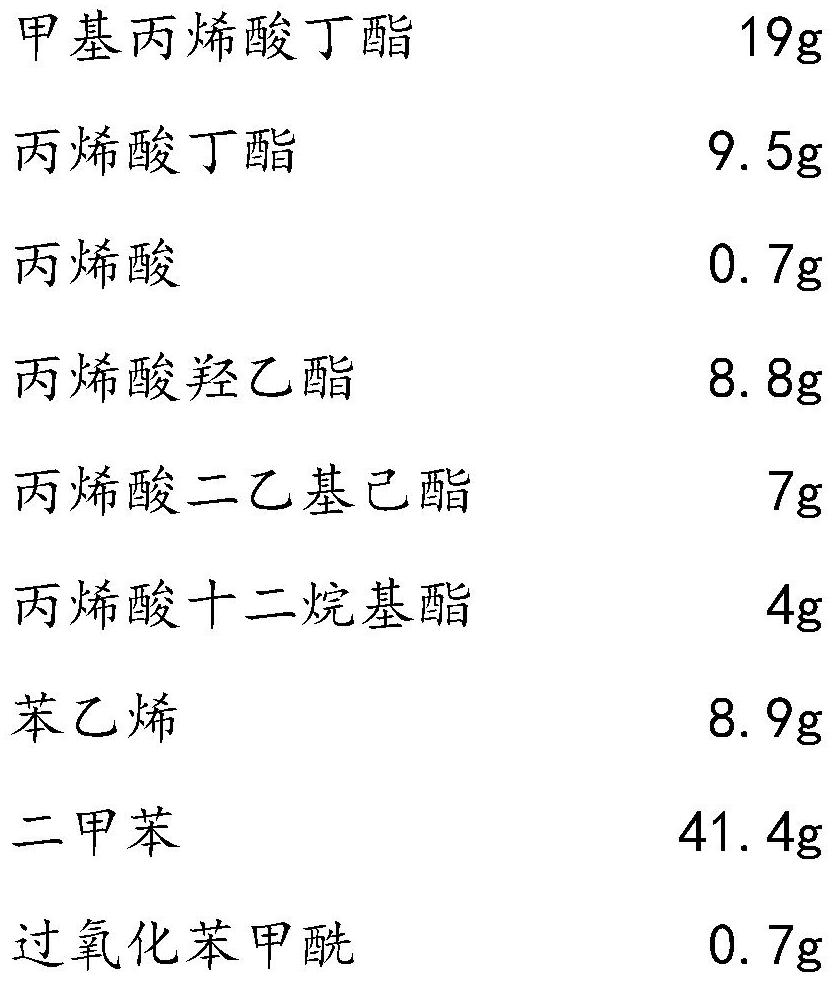

[0040]

[0041] 1) Divide xylene and benzoyl peroxide into five equal parts for subsequent use...

Embodiment 2

[0054] Preparation of a novel acrylic flexible anti-corrosion primer:

[0055] Mix 40 parts of butyl acetate, 30 parts of xylene, 15 parts of mixed dibasic acid ester, and 15 parts of propylene glycol methyl ether acetate to obtain a diluent.

[0056] 48g of homemade flexible acrylic resin with a solid content greater than 45%, 0.6g of dispersant DA-703-50, 14g of titanium dioxide, 7g of zinc yellow, 8g of talcum powder, 5g of zinc phosphate, 1.2g of mica powder, 1.2g of light calcium, Add 0.2g of bentonite and 3.9g of diluent into the mixing container and stir in sequence, then grind until the particle size is below 35μm, add 0.2g of leveling agent LHP91, 0.3g of adhesion promoter EDL-6019B, 0.4g of ultraviolet absorber Tinuvin 5060 and dilute 10g of the agent is used to adjust the solid content to be more than 55% to obtain the first component.

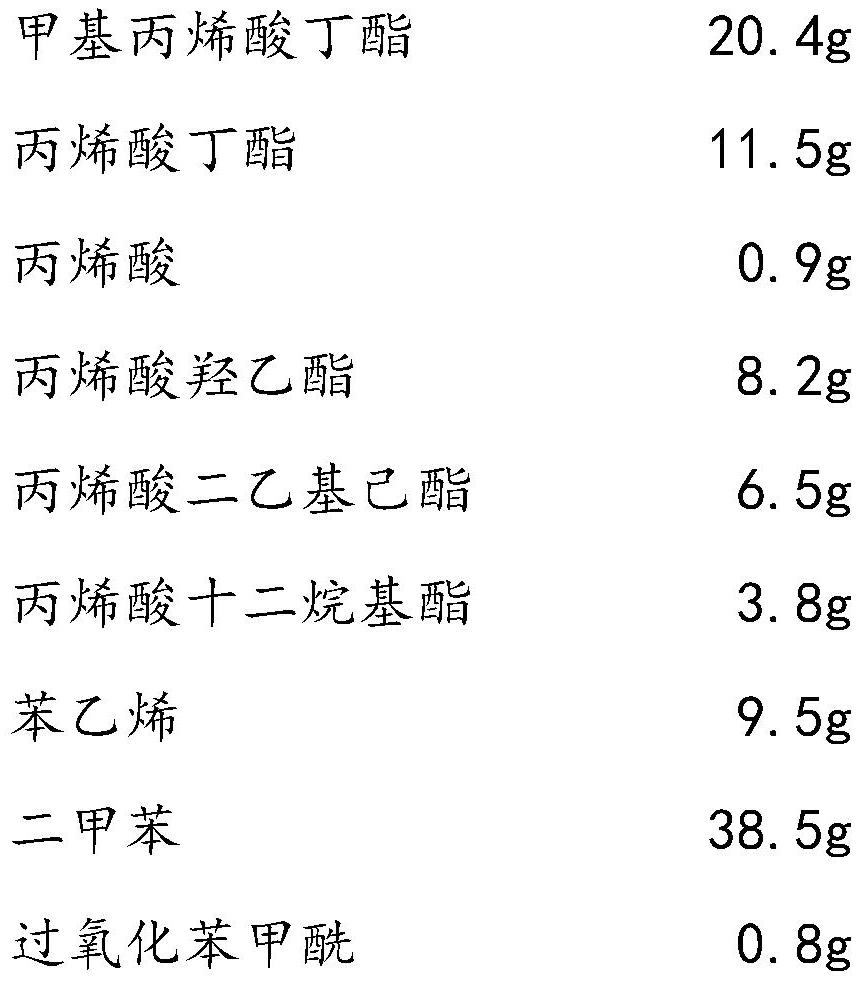

[0057] Where: Homemade flexible acrylic

[0058]

[0059] 1) Divide xylene and benzoyl peroxide into five equal parts for sub...

Embodiment 3

[0072] Preparation of a novel acrylic flexible anti-corrosion primer:

[0073] Mix 45 parts of butyl acetate, 35 parts of xylene, 10 parts of mixed dibasic acid ester, and 10 parts of propylene glycol methyl ether acetate to obtain a diluent.

[0074] 50g self-made flexible acrylic resin with a solid content greater than 45%, 0.8g dispersant BYK110, 13g titanium dioxide, 7g zinc yellow, 7g talcum powder, 5g zinc phosphate, 2g mica powder, 2g light calcium, 0.3g bentonite, diluent Add 1.8g into the mixing container and stir in turn, then grind until the particle size is below 35μm, add 0.3g of leveling agent BYK300, 0.4g of adhesion promoter EDL-6019B, 0.4g of ultraviolet absorber Tinuvin 5060 and 10g of diluent to adjust the solid content to More than 55% get the first component.

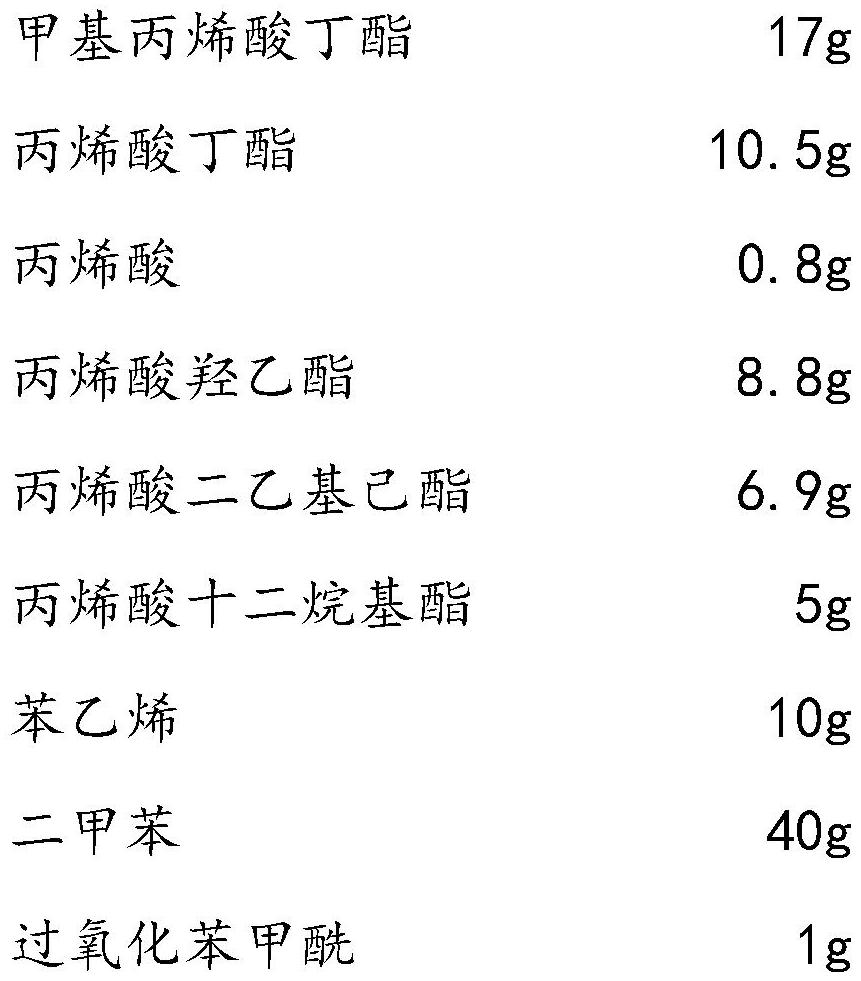

[0075] Where: Homemade flexible acrylic

[0076]

[0077] 1) Divide xylene and benzoyl peroxide into five equal parts for subsequent use according to the specified amount in the formula;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com