A kind of calcium carbonate modified vegetable fiber tableware for children and preparation method thereof

A plant fiber and calcium carbonate technology, applied in the field of tableware materials, can solve the problems of poor water resistance and impact resistance, and achieve the effects of low cost, not easy to crack, and increased bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

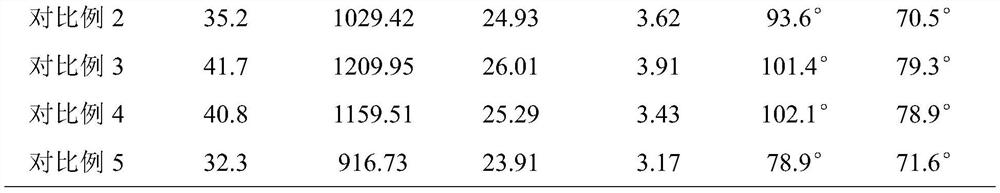

Examples

Embodiment 1

[0024] A calcium carbonate modified vegetable fiber tableware for children, the raw materials of which include 70 parts by weight of composite fiber powder, 15 parts of food-grade calcium carbonate ultrafine powder, 2 parts of vegetable pectin, 1 part of shellac resin, 1 part of carboxymethyl chitosan and 1 part epoxy silane. The raw materials were taken and mixed well, preheated at 90° C. for 2 minutes, and then molded at 145° C. for 8 minutes under the conditions of a pressure of 30 MPa to obtain children’s tableware.

[0025] Among them, the composite fiber is made by mixing straw fiber and wood fiber, and the composite fiber powder is obtained by mixing the fiber raw materials with 5wt% malic acid solution, then treating at 40°C and 2MPa for 18h, and finally drying and grinding.

[0026] Wherein, food-grade calcium carbonate ultrafine powder is obtained by the following operations:

[0027] (1) one-time treatment: under the condition of stirring, the calcium carbonate slu...

Embodiment 2

[0030] A calcium carbonate-modified vegetable fiber tableware for children, the raw materials by weight include 80 parts of composite fiber powder, 20 parts of food-grade calcium carbonate ultrafine powder, 4 parts of vegetable pectin, 3 parts of shellac resin, 2 parts of carboxymethyl chitosan and 2 parts styrylsilane. The raw materials were taken and mixed, preheated at 95°C for 1.5 minutes, and then molded at 150°C under the conditions of 32 MPa for 6 minutes to obtain children's tableware.

[0031] Among them, the composite fiber is made by mixing straw fiber and bagasse fiber, and the composite fiber powder is obtained by mixing the fiber raw materials with 35wt% tartaric acid solution, then treating at 80°C and 5MPa for 10 hours, and finally drying and grinding.

[0032] Wherein, food-grade calcium carbonate ultrafine powder is obtained by the following operations:

[0033] (1) one-time treatment: under the condition of stirring, the calcium carbonate slurry that the so...

Embodiment 3

[0036] A calcium carbonate-modified vegetable fiber tableware for children, the raw materials of which include 90 parts by weight of composite fiber powder, 25 parts of food-grade calcium carbonate ultrafine powder, 5 parts of vegetable pectin, 5 parts of shellac resin, and 4 parts of carboxymethyl. base chitosan and 3 parts vinyl silane. The raw materials were taken and mixed, preheated at 100° C. for 1 min, and then molded at 155° C. for 0.5 min under the conditions of a pressure of 35 MPa to obtain children’s tableware.

[0037] Among them, the composite fiber is made by mixing bagasse fiber and bamboo pulp fiber, and the composite fiber powder is obtained by mixing the fiber raw materials with 70wt% malic acid solution, then treating at 120°C and 8MPa for 0.5h, and finally drying and grinding.

[0038] Wherein, food-grade calcium carbonate ultrafine powder is obtained by the following operations:

[0039] (1) one-time treatment: under the condition of stirring, the calciu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com