Polyimide aerogel and preparation method thereof

A technology of polyimide and airgel, which is applied in the field of airgel, and can solve the problems of cumbersome organic solvent replacement steps and high gel density in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

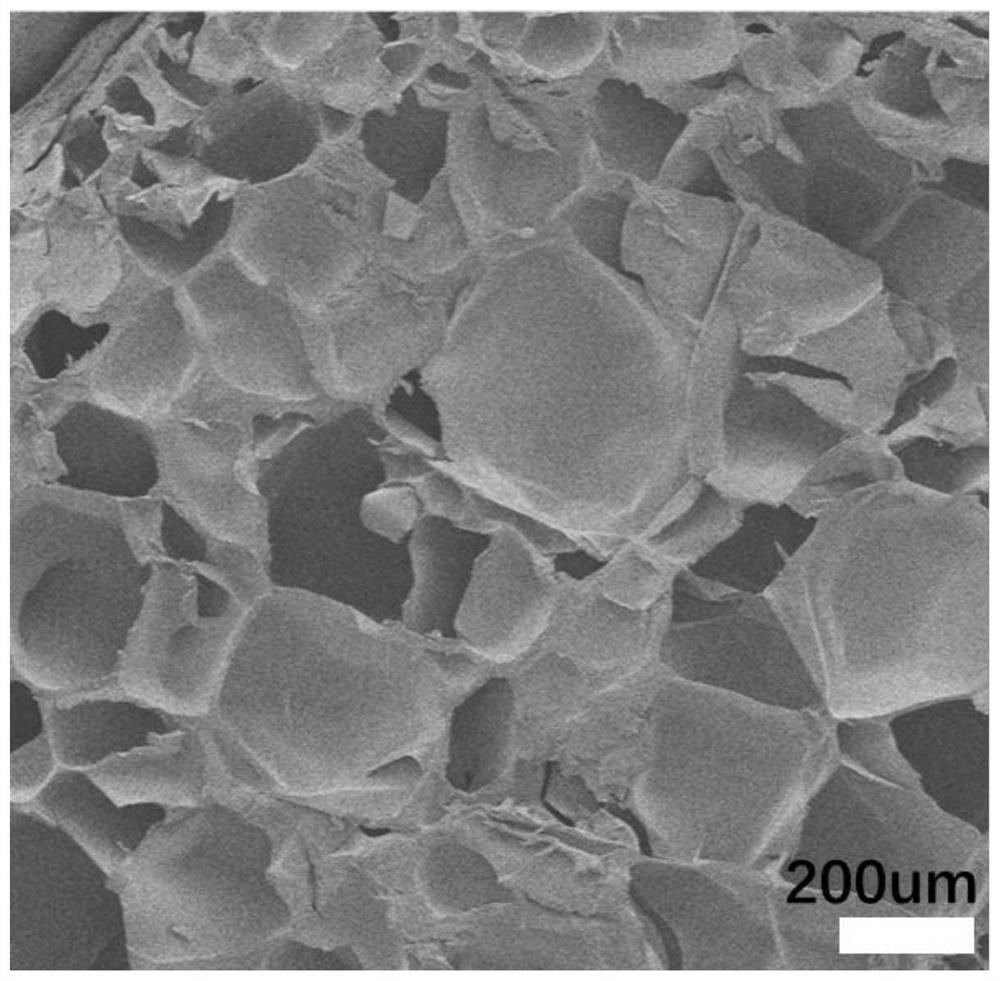

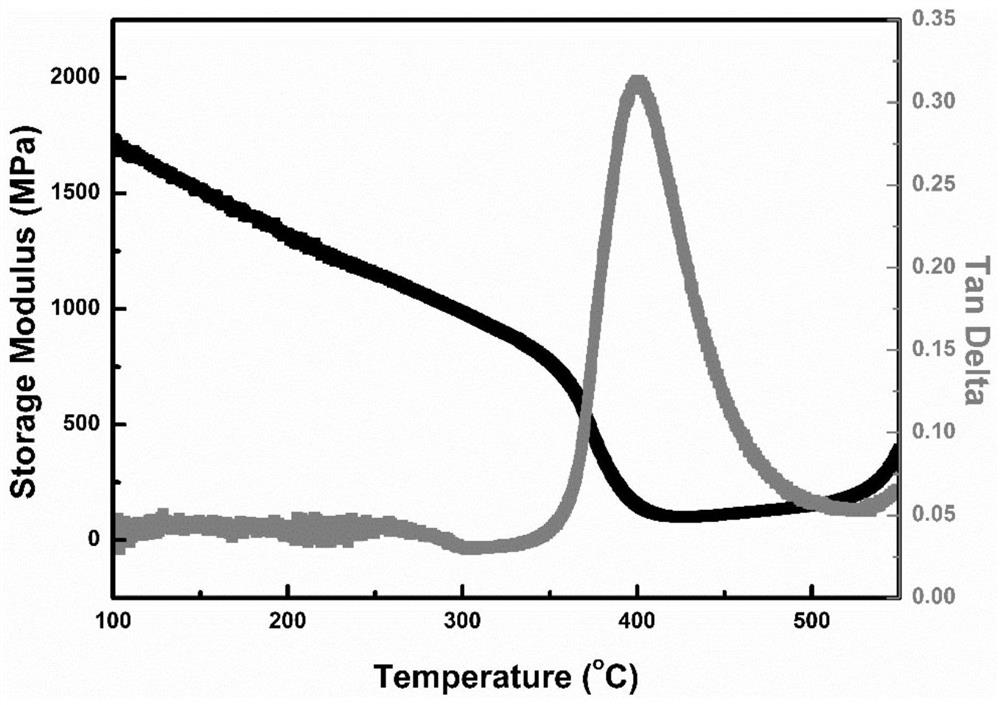

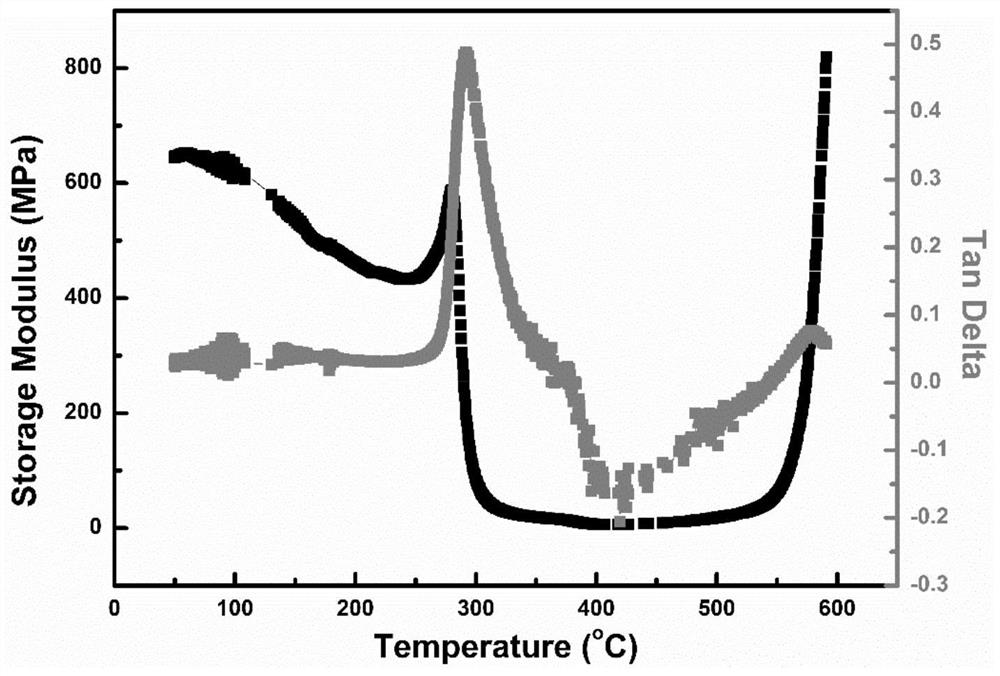

Image

Examples

Embodiment 1

[0054] 1. Dissolve 7.89g of pyromellitic anhydride (PMDA) and 7.11g of 4,4`-diaminodiphenyl ether (ODA) (the molar ratio of dianhydride and diamine is 1.02:1) in 85.0g of N , in N-dimethylformamide (DMF) (the mass ratio of solute to solvent is 15:85), in N 2 Mix under the protection of an inert gas, stir and react at 25°C for 6 hours, and obtain a polyamic acid (PAA) solution after the reaction; then add the PAA solution dropwise to water to precipitate, filter, wash, and dry to obtain PAA powder.

[0055] 2. Add 5.0g of PAA (0.024mol of carboxyl moles) powder into 95.0g of water to disperse, then add 1.21g (0.012mol) triethylamine and stir for a while, then add 0.56g (0.0048mol) tetramethylethylamine The diamine continued to stir, and after the polyamic acid was completely dissolved and the solution was clear and transparent, it was left to stand for 2 hours to make the solution produce sol-gel.

[0056] 3. Before freezing, place the gelled sample in a refrigerator at 4°C to...

Embodiment 2

[0059] 1. Dissolve 3.58g of PMDA, 4.83g of biphenyltetracarboxylic dianhydride (BPDA) and 6.58g of ODA (the molar ratio of dianhydride and diamine is 1.02:1, wherein the molar ratio of PMDA to BPDA is 1:1) In 85.0g of N,N-dimethylformamide (DMF) (the mass ratio of solute to solvent is 15:85), in N 2 Mix under the protection of an inert gas, stir and react at 25°C for 6 hours, and obtain a polyamic acid (PAA) solution after the reaction; then add the PAA solution dropwise to water to precipitate, filter, wash, and dry to obtain PAA powder.

[0060] 2. Add 5.0 g of PAA (0.022 mol of carboxyl moles) powder into 95.0 g of water to disperse, then add 1.11 g (0.011 mol) triethylamine and stir for a while, then add 0.51 g (0.0044 mol) tetramethylethylamine The diamine continued to stir, and after the polyamic acid was completely dissolved and the solution was clear and transparent, it was left to stand for 4 hours to make the solution produce sol-gel.

[0061] 3. Before freezing, pl...

Embodiment 3

[0064] 1. Mix 4.61g of 3,3',4,4'-benzophenone tetracarboxylic dianhydride (BTDA), 6.37g of 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6FDA), 2.60g ODA and 1.41g of terephthalic anhydride (PDA) (the molar ratio of dianhydride and diamine is 1.10:1, wherein the molar ratio of BTDA to 6FDA is 1:1, and the molar ratio of ODA to PDA is 1:1) is dissolved in 85.0 g of N,N-dimethylacetamide (DMAc) (the mass ratio of solute to solvent is 15:85), in N 2 Mix under the protection of an inert gas, stir and react at 25°C for 6 hours, and obtain a polyamic acid (PAA) solution after the reaction; then add the PAA solution dropwise to water to precipitate, filter, wash, and dry to obtain PAA powder.

[0065] 2. Add 15.0 g of PAA (0.057 mol of carboxyl moles) powder into 85.0 g of water for dispersion, then add 4.04 g (0.040 mol) of triethylamine and stir for a while, then add 1.32 g (0.011 mol) of tetramethylethane The diamine continued to stir, and after the polyamic acid was comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com