Application of nitrogen-doped carbon-coated Co and/or Co3ZnC composite material in preparation of lithium-sulfur battery diaphragm

A technology of nitrogen-doped carbon and composite materials, which is applied in the direction of lithium batteries, carbon preparation/purification, carbon compounds, etc., can solve the problems of poor affinity and not enough to effectively inhibit the shuttle effect of polysulfides, and achieve novel structures and improved Electrochemical performance, the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] (2) Preparation of positive pole piece: 25% super P and 75% sublimated sulfur are fully ground in an agate mortar for 15 minutes, then placed in a stainless steel reaction kettle, and then placed in an oven at 155°C for 10h, the reaction is over Get super P-S composite. Put 80% super P-S, 10% super P and 10% PVDF in an agate mortar, and use N-methylpyrrolidone (NMP) as a solvent to thoroughly grind for 30 minutes, and then apply the resulting slurry evenly with a doctor blade on aluminum foil. After fully drying, the obtained pole pieces were cut into discs with a diameter of 14 mm.

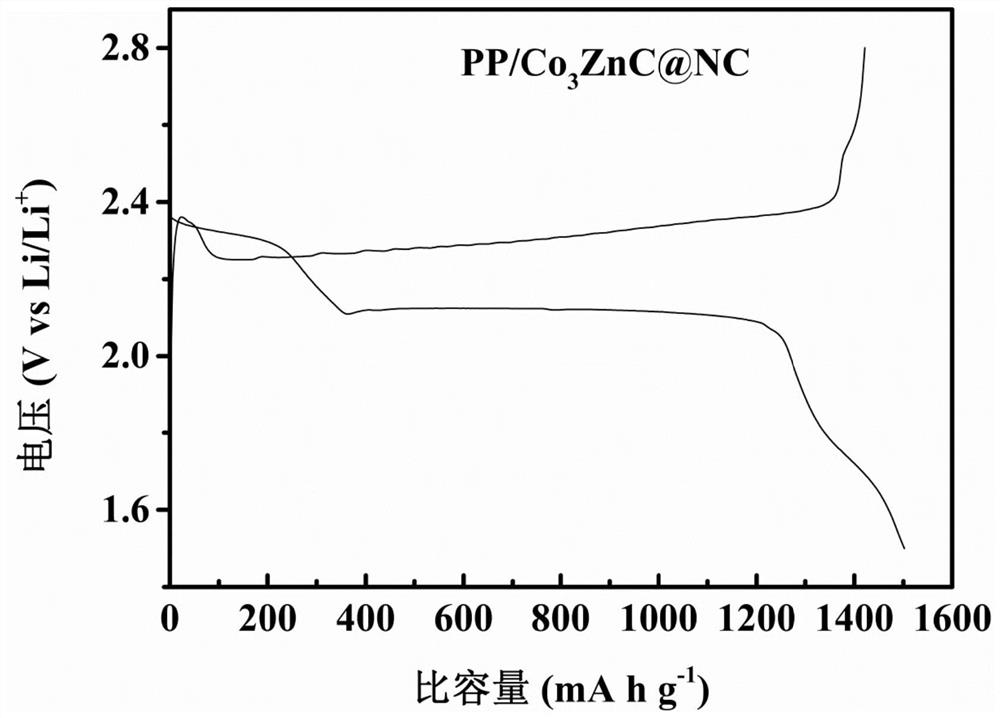

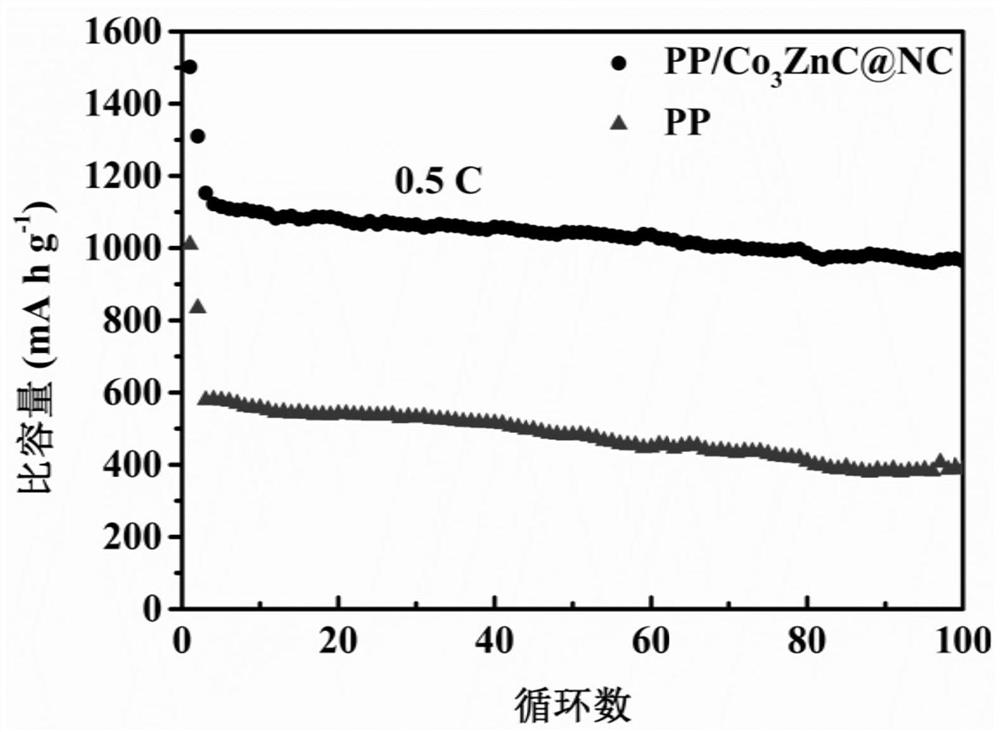

[0043] (3) Assembly of button cell: the following operations were performed in a glove box filled with argon. The assembly of CR2025 button cell is respectively using lithium sheet as negative electrode, super P-S as positive electrode, PP / nitrogen-doped carbon-coated cobalt-zinc composite material as diaphragm and LITFIS electrolyte (1.0M LiTFSI in DOL:DME=1: 1Vol%with 1.0%LiNO 3 , Su...

Embodiment 1

[0046] Nitrogen-doped carbon-coated Co in this example 3 ZnC composite Co 3 The preparation method of ZnC@NC, the specific steps are as follows:

[0047] 1gPluronic F-127, 2g dicyandiamide, 0.1303g Co(NO 3 ) 2 6H 2 O and 0.3994g Zn(NO 3 ) 2 6H 2 O was fully dissolved in water in turn, and after continuing to stir overnight, the solution was placed in an oil bath at 80°C, and the water was dried, and then placed in an oven at 80°C to continue drying. Finally, the dried samples were placed in a tube furnace under N 2 Under the protection of the atmosphere, the temperature was raised to 700°C at a rate of 3°C / min, and the sample obtained after high-temperature carbonization for 1 hour was Co 3 ZnC@NC.

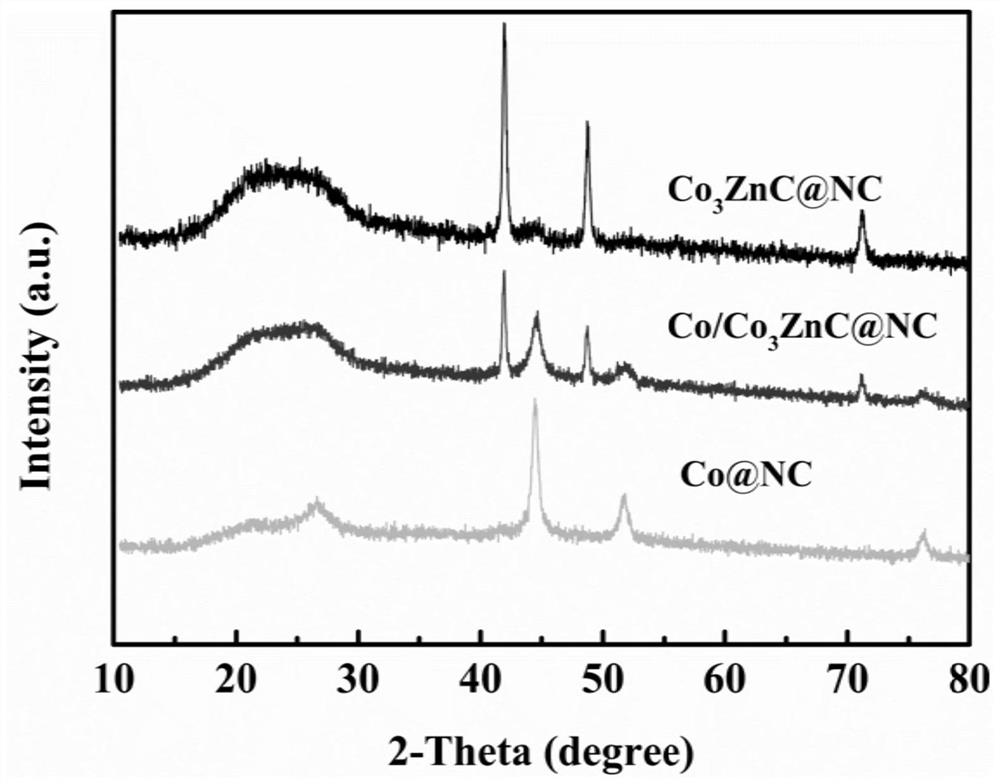

[0048] Co in this example 3 The XRD pattern of ZnC@NC is as follows figure 1 Shown, Co 3 There are three main peaks in the XRD diffraction pattern of ZnC@NC composites, and the diffraction peaks at 41.90°, 48.79° and 71.48° correspond to Co 3 (111), (200) and (220) c...

Embodiment 2

[0051] Nitrogen-doped carbon-coated Co / Co in this embodiment 3 ZnC Composite Co / Co 3 The preparation method of ZnC@NC, the specific steps are as follows:

[0052] 1gPluronic F-127, 2g dicyandiamide, 0.1303g Co(NO 3 ) 2 6H 2 O and 0.2663g Zn(NO 3 ) 2 6H 2 O was fully dissolved in water in turn, and after continuing to stir overnight, the solution was placed in an oil bath at 80°C, and the water was dried, and then placed in an oven at 80°C to continue drying. Finally, the dried samples were placed in a tube furnace under N 2 Under the protection of the atmosphere, the temperature was raised to 700°C at a rate of 3°C / min, and the sample obtained after high-temperature carbonization for 2 hours was Co / Co 3 ZnC@NC.

[0053] Co / Co in this example 3 The XRD pattern of ZnC@NC is as follows figure 1 Shown, Co / Co 3 There are six main peaks in the XRD diffraction pattern of ZnC@NC composites, among which the diffraction peaks at 41.90°, 48.79° and 71.48° correspond to Co 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial discharge specific capacity | aaaaa | aaaaa |

| Initial discharge specific capacity | aaaaa | aaaaa |

| Initial discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com