A failure analysis method for long-distance natural gas pipelines

A technology of long-distance pipeline and analysis method, which is applied in the field of natural gas long-distance pipeline detection, can solve the problems of inaccurate failure risk and damage to pipeline safety, achieve accurate failure period and service life, reduce inspection and detection costs, and realize convenient implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

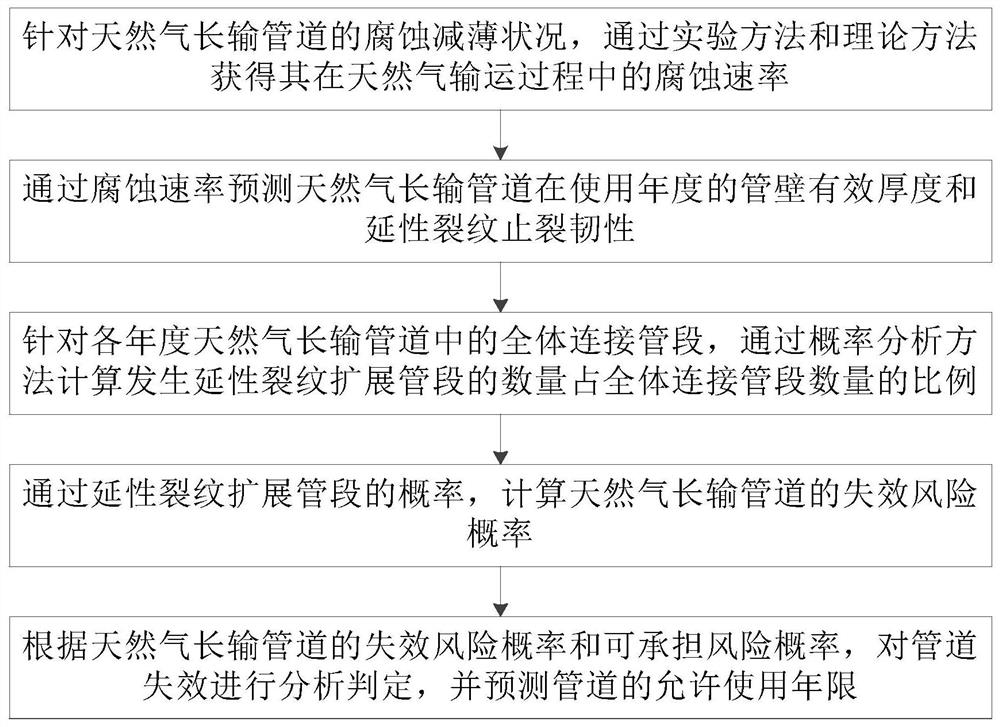

[0038] like figure 1 As shown, the method for analyzing the failure of the natural gas long-distance pipeline of the present invention comprises the following steps:

[0039] Step 1. According to the corrosion and thinning status of the natural gas long-distance pipeline, the corrosion rate in the natural gas transportation process is obtained by experimental methods and theoretical methods;

[0040] Step 2. Predict the effective thickness of the pipe wall and the ductile crack arrest toughness of the natural gas long-distance pipeline in the service year through the corrosion rate;

[0041] Step 3: For all the connecting pipe sections in the long-distance natural gas transmission pipeline in each year, calculate the ratio of the number of pipe sections with ductile crack propagation to the total number of connecting pipe sections through the probability analysis method;

[0042] Step 4: Calculate the probability of failure risk of the long-distance natural gas pipeline throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com