A kind of titanium alloy blade protective coating and preparation method thereof

A protective coating, titanium alloy technology, applied in metal material coating process, coating, vacuum evaporation coating and other directions, can solve the problems of easy corrosion on the surface of titanium alloy gas turbine blades, short service life, etc., to achieve coating compactness Excellent, improved high temperature oxidation resistance, good process repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

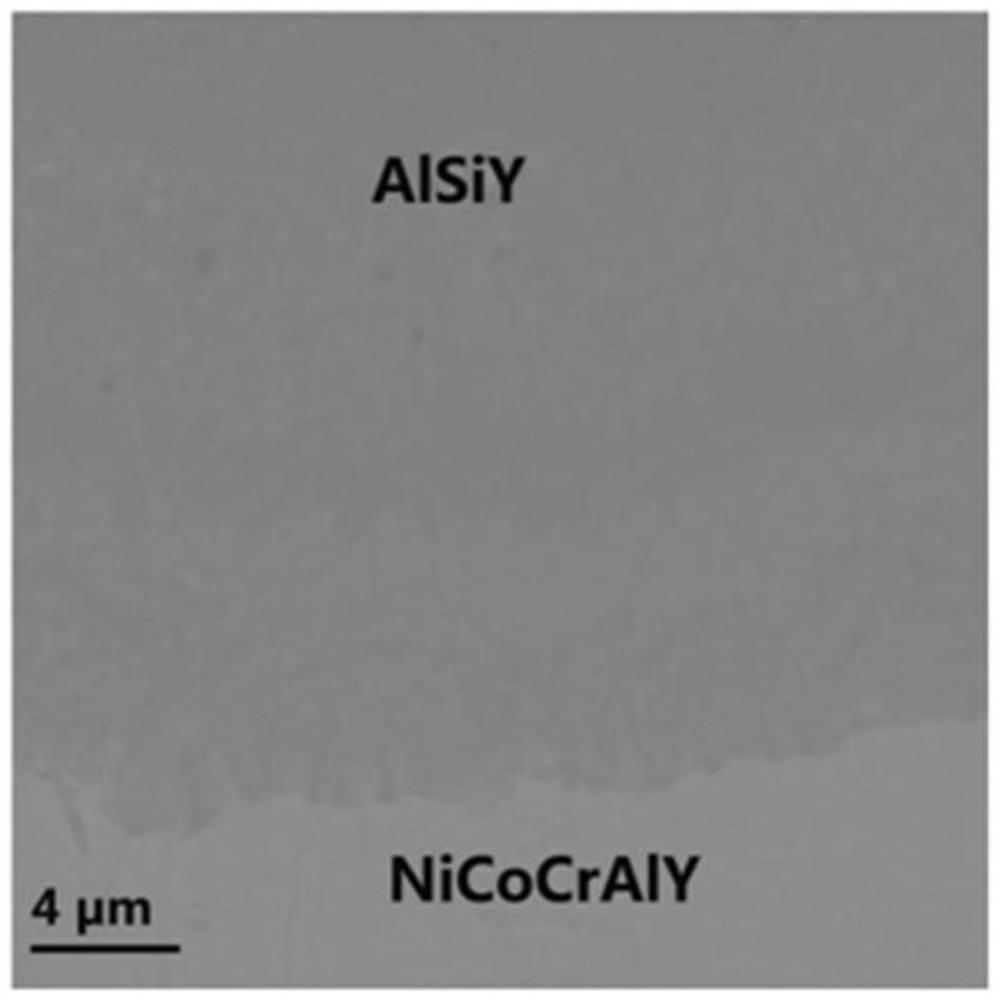

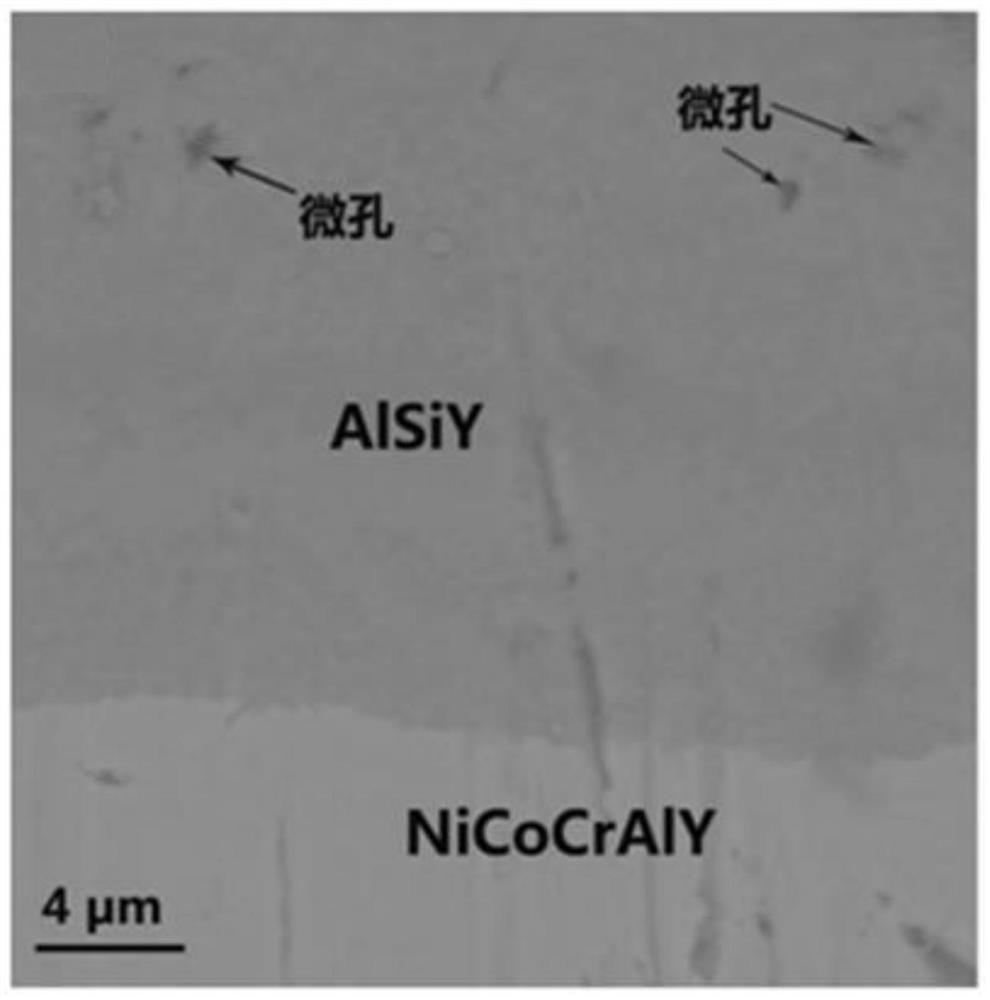

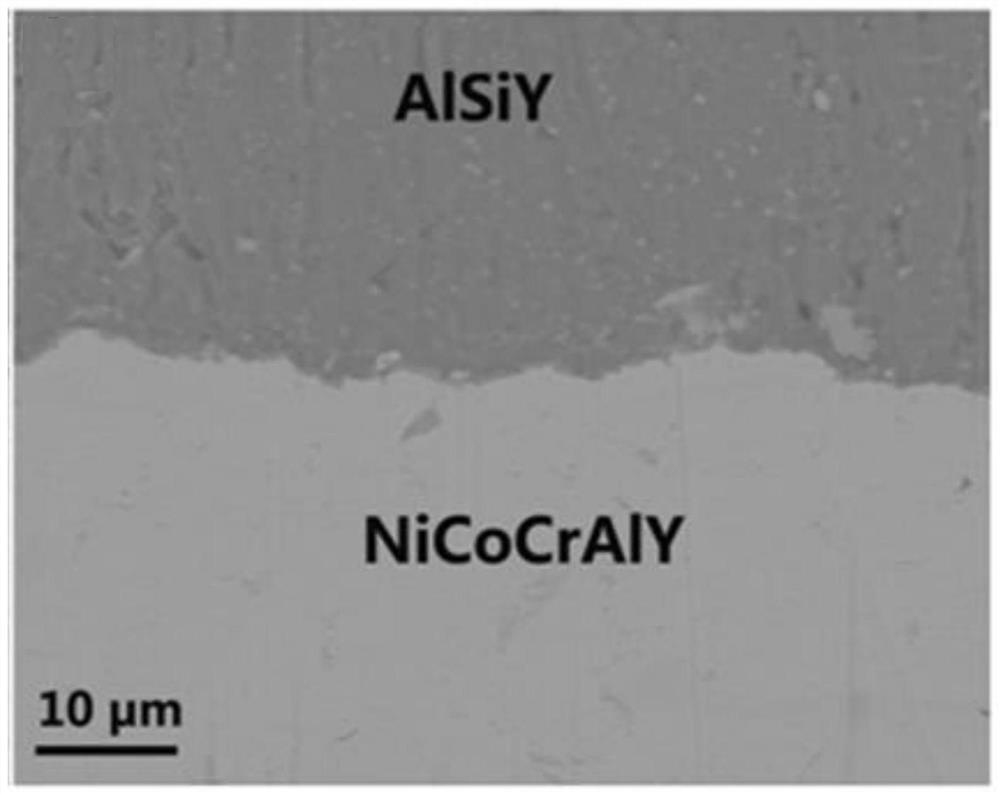

[0024] The base material is titanium alloy (grade Ti6Al4V), the size of the sample is 20mm×10mm×10mm, and the size of the coating surface is 15mm×15mm. The MCrAlY / AlSiY composite coating is deposited on the substrate by arc ion plating (AIP). The composition of the MCrAlY target is (mass percentage): Co: 26, Cr: 22, Al: 12, Y: 0.5, Ni: remainder; The AlSiY target composition (mass percentage) is Al: 88.5, Si: 11, Y: 0.9.

[0025] A specific preparation method of a titanium alloy blade protective coating:

[0026] Step 1, sandblasting the substrate before deposition, and then performing ultrasonic cleaning and drying for later use;

[0027] Step 2, using domestic arc ion plating equipment to deposit MCrAlY / AlSiY composite coating, the vacuum degree in the vacuum chamber reaches 4.8×10 -3 At Pa, argon gas is introduced into the vacuum chamber, the air pressure is controlled at 1.7Pa, the negative pulse voltage is applied to the substrate at -160V, and the pulse duty ratio is 6...

Embodiment 2

[0035] The composition of the base material and the process parameters refer to the examples. The difference from Example 1 lies in the preparation method. The specific preparation method in this example is as follows:

[0036] Step 1, sandblasting the substrate before deposition, and then performing ultrasonic cleaning and drying for later use;

[0037] Step 2, using domestic arc ion plating equipment to deposit MCrAlY / AlSiY composite coating, the vacuum degree in the vacuum chamber reaches 4.8×10 -3At Pa, argon gas is introduced into the vacuum chamber, the air pressure is controlled at 1.7Pa, the negative pulse voltage is applied to the substrate at -160V, and the pulse duty ratio is 65%. The gas glow discharge is enhanced by the arc to glow the surface of the substrate. Discharge ion cleaning for 60 minutes;

[0038] Step 3, adjust the Ar gas flow, control the air pressure in the vacuum chamber at 1.3Pa, add pulse negative bias to the substrate at -120V, the pulse duty cy...

Embodiment 3

[0043] The composition of the base material and the process parameters refer to the examples. The difference from Example 1 lies in the preparation method. The specific preparation method in this example is as follows:

[0044] Step 1, sandblasting the substrate before deposition, and then performing ultrasonic cleaning and drying for later use;

[0045] Step 2, using domestic arc ion plating equipment to deposit MCrAlY / AlSiY composite coating, the vacuum degree in the vacuum chamber reaches 4.8×10 -3 At Pa, argon gas is introduced into the vacuum chamber, the air pressure is controlled at 1.7Pa, the negative pulse voltage is applied to the substrate at -160V, and the pulse duty ratio is 65%. The gas glow discharge is enhanced by the arc to glow the surface of the substrate. Discharge ion cleaning for 60 minutes;

[0046] Step 3, adjust the Ar gas flow, control the air pressure in the vacuum chamber at 1.3Pa, add pulse negative bias to the substrate at -120V, the pulse duty c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com