Titanium-containing copper-based powder metallurgy friction material and preparation method thereof

A technology of powder metallurgy and friction materials, which is applied in the field of copper-based powder metallurgy friction materials containing titanium and its preparation, can solve the problems of unstable friction coefficient, increased wear, poor friction performance at high temperature, etc., to improve the comprehensive friction and wear performance, Effects of hardness increase, friction coefficient and wear loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

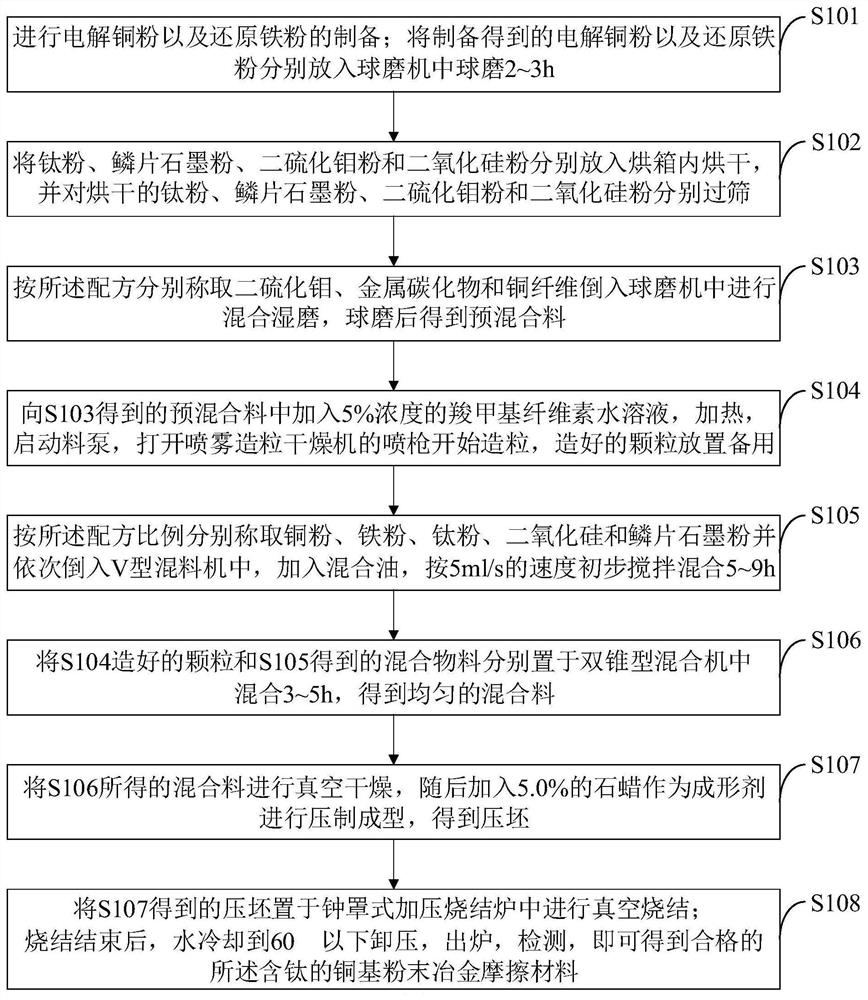

[0032] Such as figure 1 As shown, the preparation method of the titanium-containing copper-based powder metallurgy friction material provided by the embodiment of the present invention includes the following steps:

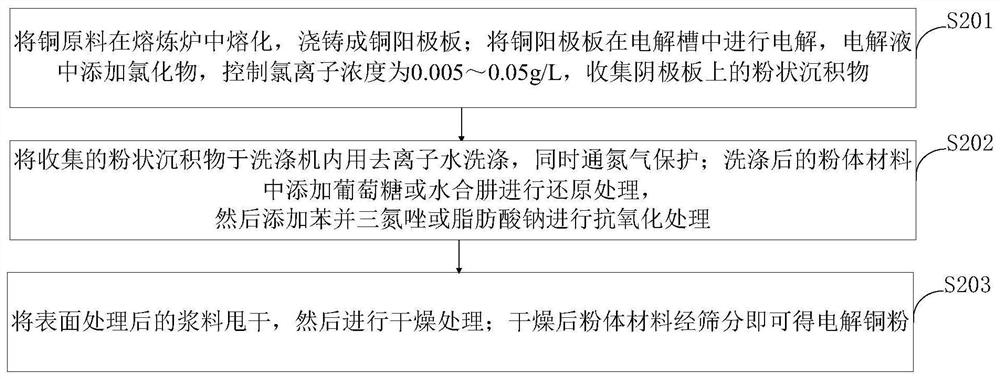

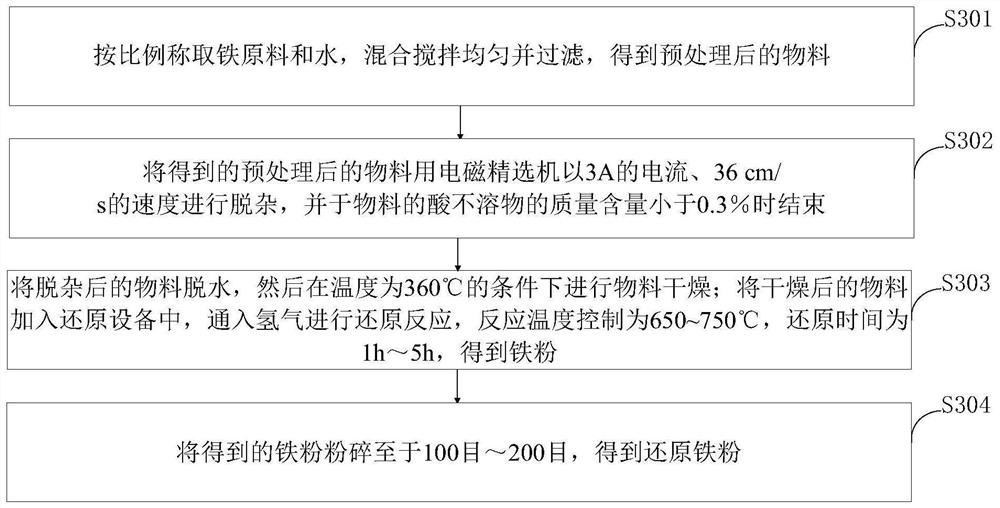

[0033] S101 , preparing electrolytic copper powder and reduced iron powder; respectively putting the prepared electrolytic copper powder and reduced iron powder into a ball mill for ball milling for 2-3 hours.

[0034] S102, put the titanium powder, flake graphite powder, molybdenum disulfide powder and silicon dioxide powder into an oven to dry respectively, and dry the dried titanium powder, flake graphite powder, molybdenum disulfide powder and silicon dioxide powder respectively. screen.

[0035] S103, weigh the molybdenum disulfide, metal carbide and copper fiber respectively according to the formula and pour them into a ball mill for mixed wet grinding, and obtain a premixed material after ball milling.

[0036] S104, add 5% carboxymethyl cellulose aqueous s...

Embodiment 1

[0071] The preparation method of titanium-containing copper-based powder metallurgy friction material is as follows:

[0072] (1) Prepare 30 parts of electrolytic copper powder and 20 parts of reduced iron powder; put the prepared electrolytic copper powder and reduced iron powder into a ball mill for ball milling for 2-3 hours.

[0073] (2) Put 15 parts of titanium powder, 6 parts of flake graphite powder, 10 parts of molybdenum disulfide powder and 8 parts of silicon dioxide powder into the oven for drying, and dry the dried titanium powder, flake graphite powder, disulfide Molybdenum powder and silicon dioxide powder were sieved separately.

[0074] (3) According to the formula, 10 parts of molybdenum disulfide, 5 parts of metal carbide and 3 parts of copper fiber were weighed and poured into a ball mill for mixed wet grinding, and the premix was obtained after ball milling.

[0075] (4) Add 5% carboxymethyl cellulose aqueous solution to the obtained premix, heat, start th...

Embodiment 2

[0081] The preparation method of titanium-containing copper-based powder metallurgy friction material is as follows:

[0082] (1) Prepare 40 parts of electrolytic copper powder and 30 parts of reduced iron powder; put the prepared electrolytic copper powder and reduced iron powder into a ball mill for ball milling for 2-3 hours.

[0083] (2) Put 20 parts of titanium powder, 10 parts of flake graphite powder, 15 parts of molybdenum disulfide powder and 10 parts of silicon dioxide powder into the oven for drying, and dry the dried titanium powder, flake graphite powder, disulfide Molybdenum powder and silicon dioxide powder were sieved separately.

[0084] (3) According to the formula, 15 parts of molybdenum disulfide, 7 parts of metal carbide and 4 parts of copper fiber were weighed and poured into a ball mill for mixing and wet grinding, and a premix was obtained after ball milling.

[0085] (4) Add 5% carboxymethyl cellulose aqueous solution to the obtained premix, heat, sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com