Weather-resistant ultraviolet curing solvent-free spraying open transparent primer and preparation method thereof

A transparent primer and ultraviolet light technology, which is applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of environmental protection and non-compliance, and achieve the effects of enhancing anti-settling, preventing fillers from settling, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

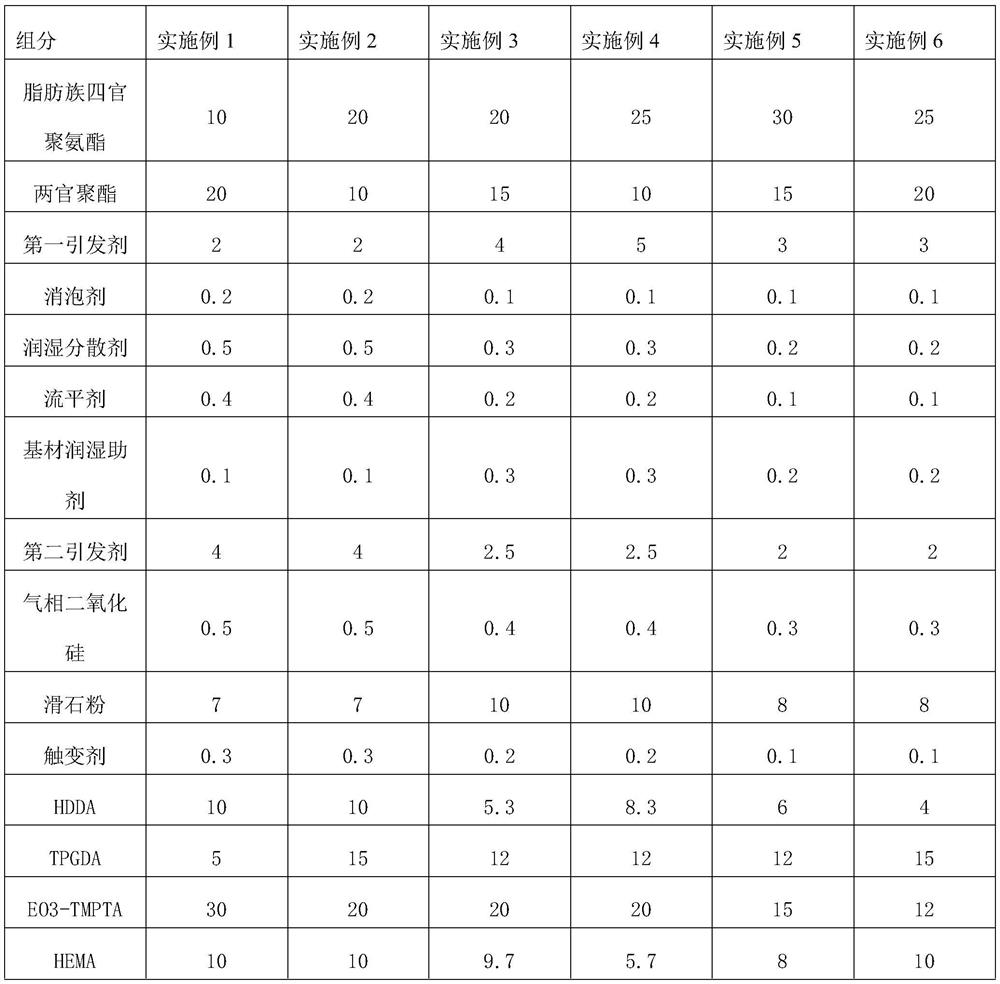

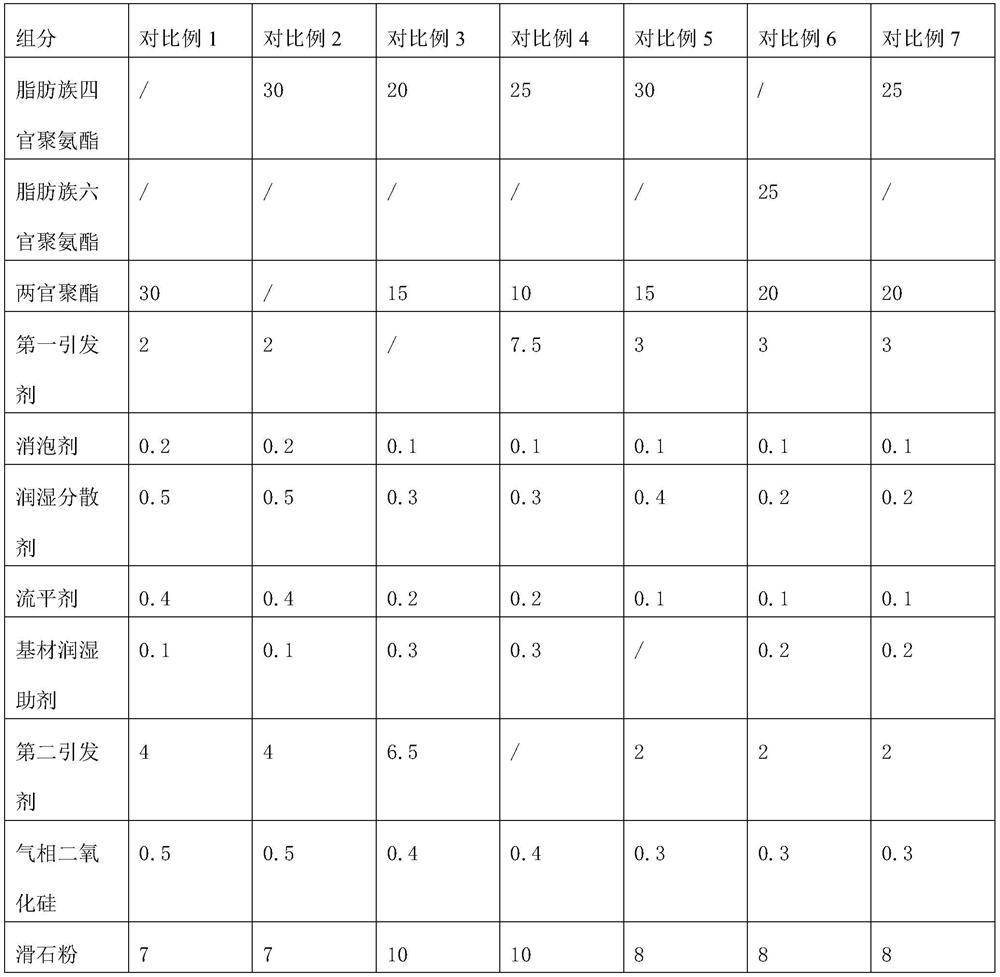

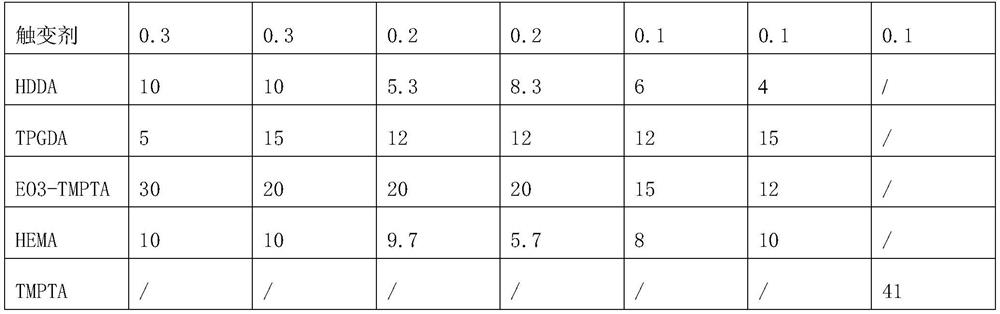

[0027] The following table is the formula table (unit: %) of 6 embodiments of the weather-resistant UV-curable solvent-free spray-coated open transparent primer of the present invention:

[0028]

[0029] A preparation method of the described weather-resistant UV-curable solvent-free spray-coated open transparent primer, comprising the following steps:

[0030] S1. Add polyurethane acrylate resin, polyester acrylic resin, defoamer and the first photoinitiator into the reactor, and disperse for 20-30min at a speed of 800-1200r / min;

[0031] S2. Add wetting and dispersing agent, leveling agent, and substrate wetting agent, and disperse at a speed of 1200-1500r / min for at least 20 minutes;

[0032] S3. Add the second photoinitiator and fumed silica, and disperse at a speed of 1200-1500r / min for at least 30min until the fineness is less than 50μm;

[0033] S4. Add talcum powder and disperse at a speed of 1200-1500r / min for at least 25min until the fineness is less than 50μm; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com