Anti-explosion high-impact anti-layer-drop combined polyurea coating and construction method thereof

A high-impact, combined technology, used in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc., to increase adhesion, reduce the amount of chain extenders, and improve explosion-proof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

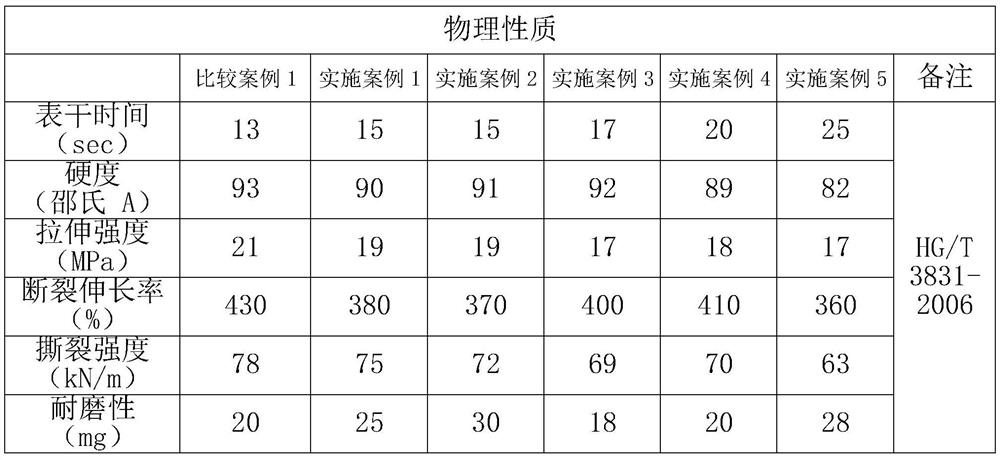

Examples

Embodiment example 1

[0045] Anti-explosion performance, high impact resistance and anti-delamination combined polyurea coating, including main agent and curing agent, the main agent and curing agent are mixed at a volume ratio of 1.15:1;

[0046] Wherein, the main agent includes: 62% of polyetheramine, 21% of diethyltoluenediamine, 8% of colorant, 1% of anti-ultraviolet agent, 1% of adhesion promoter, 0.5% of dispersant, stable 0.5% agent, 1% defoamer, 8% modified modified amino silicone oil;

[0047] The curing agent is a modified isocyanate prepolymer with a weight percentage of 100%.

[0048] Further, 40-50 wt% of diphenylmethane diisocyanate with a molecular weight of 255, 45-55 wt% of a polyol with a molecular weight of 2000 or a polyether polyol with a molecular weight of 3000 are sequentially added to the reactor, at a temperature of 70-90°C and a stirring speed React for 3-4 hours at 100-200rpm; add 8-16wt% phosphorus-based flame retardant, and mix for 30-60 minutes at a temperature of 50...

Embodiment example 2

[0062] Anti-explosion performance, high impact resistance and anti-delamination combined polyurea coating, including main agent and curing agent, the main agent and curing agent are mixed at a volume ratio of 1.12:1;

[0063] Wherein, the main agent includes: 65% of polyetheramine, 20% of diethyltoluenediamine, 8% of colorant, 1% of anti-ultraviolet agent, 1% of adhesion promoter, 0.5% of dispersant, stable Agent 0.5%, defoamer 1%, modified amino silicone oil 6%;

[0064] The curing agent is a modified isocyanate prepolymer with a weight percentage of 100%.

[0065] Further, 15-35 wt% of diphenylmethane diisocyanate with a molecular weight of 255, 45-60 wt% of carbodiimide-modified 4,4-diphenylmethane diisocyanate with a molecular weight of 275, and 45-60 wt% of a molecular weight of 2000 Polyol or polyether polyol with a molecular weight of 3000 45-55wt%, reacted for 3-4 hours at a temperature of 70-90°C and a stirring speed of 100-200rpm; Mix at 70° C. and a stirring speed...

Embodiment example 3

[0068] Anti-explosion performance, high impact resistance and anti-delamination combined polyurea coating, including main agent and curing agent, the main agent and curing agent are mixed in a weight ratio of 1.09:1;

[0069] Wherein, the main agent includes: 62% of polyetheramine, 23% of diethyltoluenediamine, 8% of colorant, 1% of anti-ultraviolet agent, 1% of adhesion promoter, 0.5% of dispersant, stable Agent 0.5%, defoamer 1%, modified amino silicone oil 6%;

[0070] The curing agent is a modified isocyanate prepolymer with a weight percentage of 100%.

[0071] Further, 15-35 wt% of diphenylmethane diisocyanate with a molecular weight of 255, carbodiimide modified 4,4 diphenylmethane diisocyanate with a molecular weight of 275, polyols with a molecular weight of 2000 or 3000 45-55wt% of the polyether polyol, reacted for 3-4 hours at a temperature of 70-90°C and a stirring speed of 100-200rpm; Mix at 100-200 rpm for 30-60 minutes to obtain a modified isocyanate prepolyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com