Preparation method and application of mordenite molecular sieve

A technology of mordenite and molecular sieve, which is applied in the direction of mercerized crystalline aluminum silicate zeolite, molecular sieve catalyst, molecular sieve and alkali exchange compound, etc., which can solve problems such as equipment corrosion, subsequent application of molecular sieve, and serious environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0079] Step 1: mix sodium hydroxide, aluminum source (the aluminum source used in embodiment 1 to embodiment 4 is sodium aluminate, the aluminum source used in embodiment 5 to embodiment 8 is aluminum sulfate) and water, add 30wt% silica sol and cetyltrimethylammonium bromide were stirred evenly, and then transferred to a stainless steel high-pressure hydrothermal reactor for pre-crystallization to obtain a silica-alumina precursor with a hydroxonite and mordenite structure.

[0080] Step 2: Mix sodium hydroxide, sodium aluminate / aluminum sulfate and water, then add 30 wt% silica sol and tetraethylammonium hydroxide, stir and age to obtain the structure-oriented sol.

[0081] Step 3: Mix the silicon-aluminum precursor obtained in step 1 and the structure-oriented sol obtained in step 2 in a certain proportion, stir evenly, and transfer the sol mixture to a stainless steel high-pressure hydrothermal reaction kettle for crystallization; after the crystallization is completed, the...

Embodiment 9

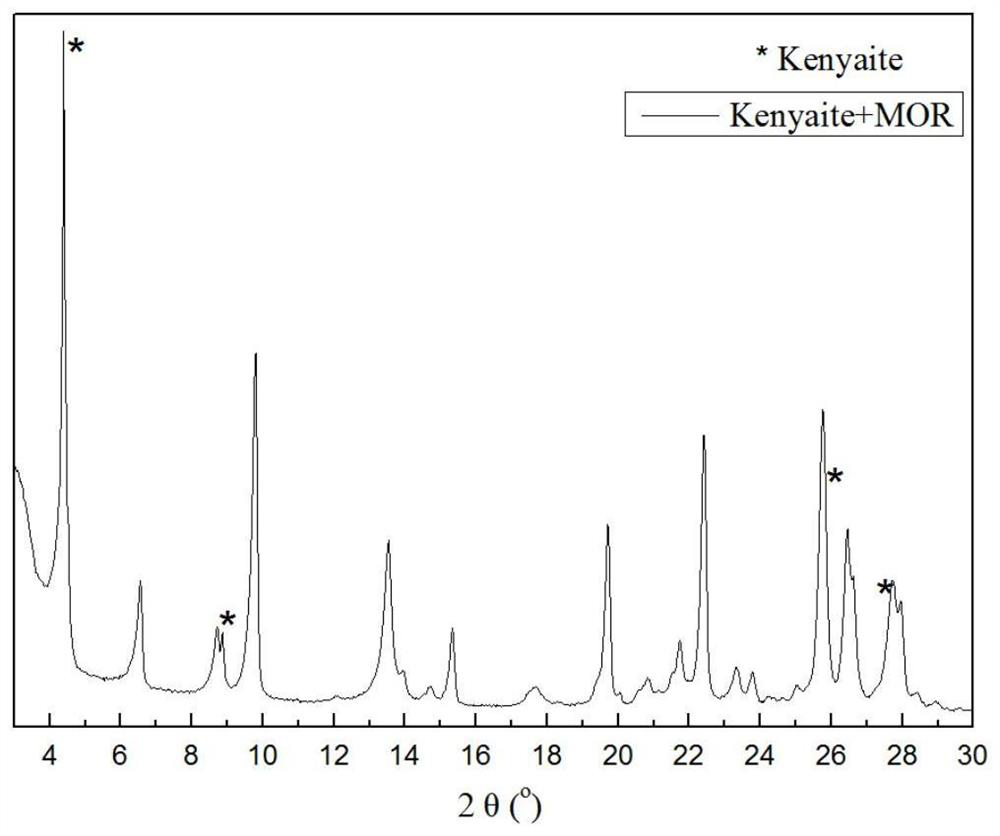

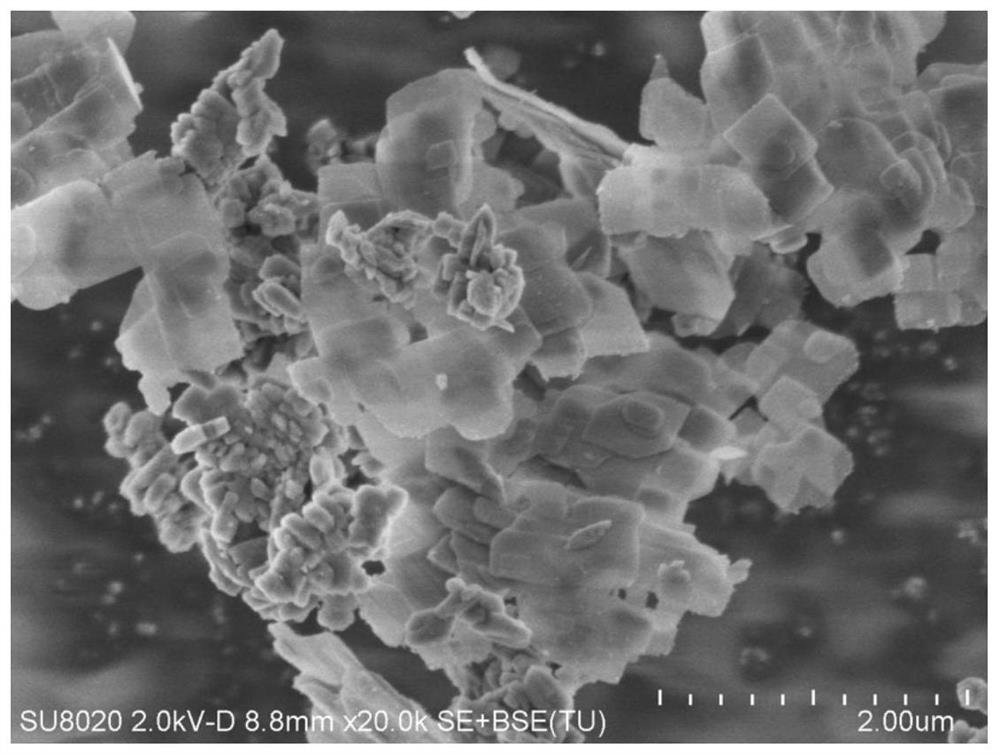

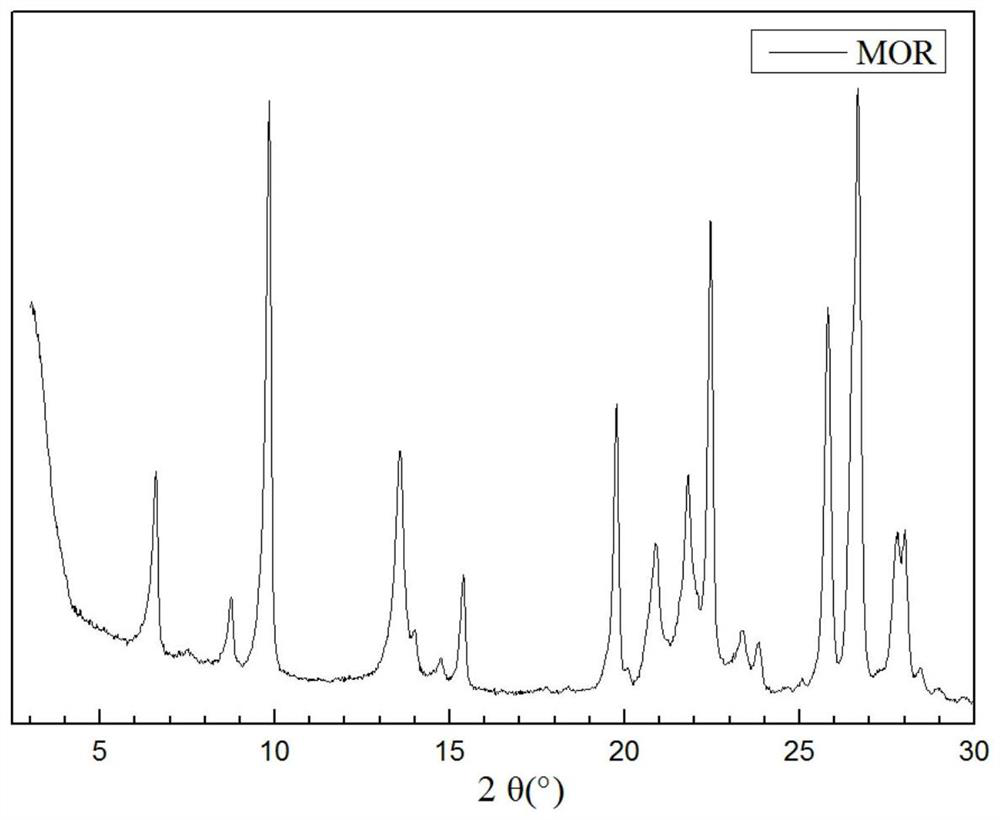

[0110] XRD analysis and characterization adopts X'Pert PRO X-ray diffractometer of PANalytical Company in the Netherlands, Cu target, Kα radiation source (λ=0.15418nm), voltage 40KV, current 40mA; SEM test instrument used is Hitachi SU8020 field emission Scanning electron microscope with an accelerating voltage of 2kV. The XRD pattern test was carried out on samples 1-8 and the intermediate product silicon-aluminum ratio precursor when preparing samples 1-8, with sample 7 as a typical representative, figure 1 It is the XRD spectrum of the silicon-aluminum precursor of sample 7. It can be seen that the sample has obvious structural characteristics of mordenite, but at the positions of 4.38°, 8.91°, 25.81° and 27.66°, hydroxosilicate zeolite appears at the same time Characteristic peaks of the structure (Kenyaite). image 3 It is the XRD spectrum of sample 7 of high silicon-aluminum ratio mordenite molecular sieve. It can be seen that this sample has obvious characteristic peak...

Embodiment 10

[0113] The product analysis was carried out on Fuli GC9790 gas chromatograph, HP-PLOT / Q column, FID detector; the conversion rate of dimethyl ether (DME) and the selectivity data of methyl acetate (MA) were calculated according to the area normalization method .

[0114] The mordenite molecular sieve catalyst samples prepared in the above examples and comparative examples were pressed into tablets, crushed and sieved, and 1g of 20-40 mesh catalyst was weighed and loaded into a fixed-bed reactor. 2 In-situ pretreatment for 3 hours, lower the temperature to 190°C, adjust the reaction pressure to 2.0MPa for activity evaluation, the reaction time is 12 hours, the feed volume ratio DME (dimethyl ether): N 2 : CO=1:45:4, the volume space velocity is 1600h -1 . Table 4 shows the catalyst evaluation results for the carbonylation of dimethyl ether to methyl acetate.

[0115] Table 4 Evaluation results of different dimethyl ether carbonylation catalyst samples

[0116] nam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com