Controllable crystalline form titanium dioxide and graphite alkene composite material with high efficient photoelectricity activity and preparation method thereof

A photoelectric activity, titanium dioxide technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., to achieve the effects of common and easy-to-obtain raw materials, low cost, and simple and safe preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Add 3ml of TiCl3 hydrochloric acid solution (volume fraction 15% to 20%) to 30ml of absolute ethanol, add 1.75ml of acetic acid, 1ml of polyethylene glycol 200 (PEG200) and 0.2g of urea in succession under continuous stirring, and make the prepared The reaction solution is put into a hydrothermal reaction kettle, reacted at 150-180°C for 10-12 hours, cooled, the precipitate in the product is separated, washed with water and alcohol, filtered, and dried to obtain the product.

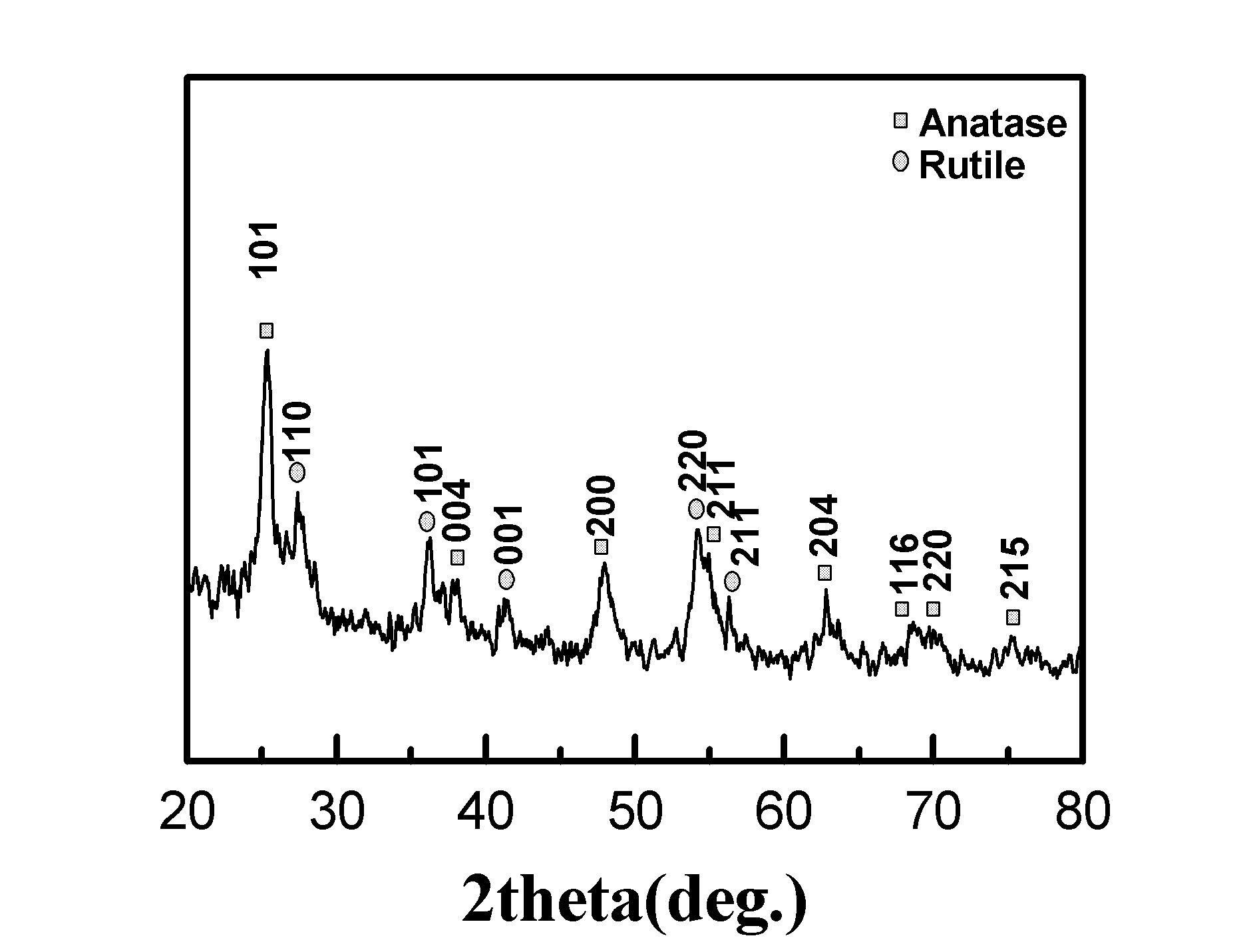

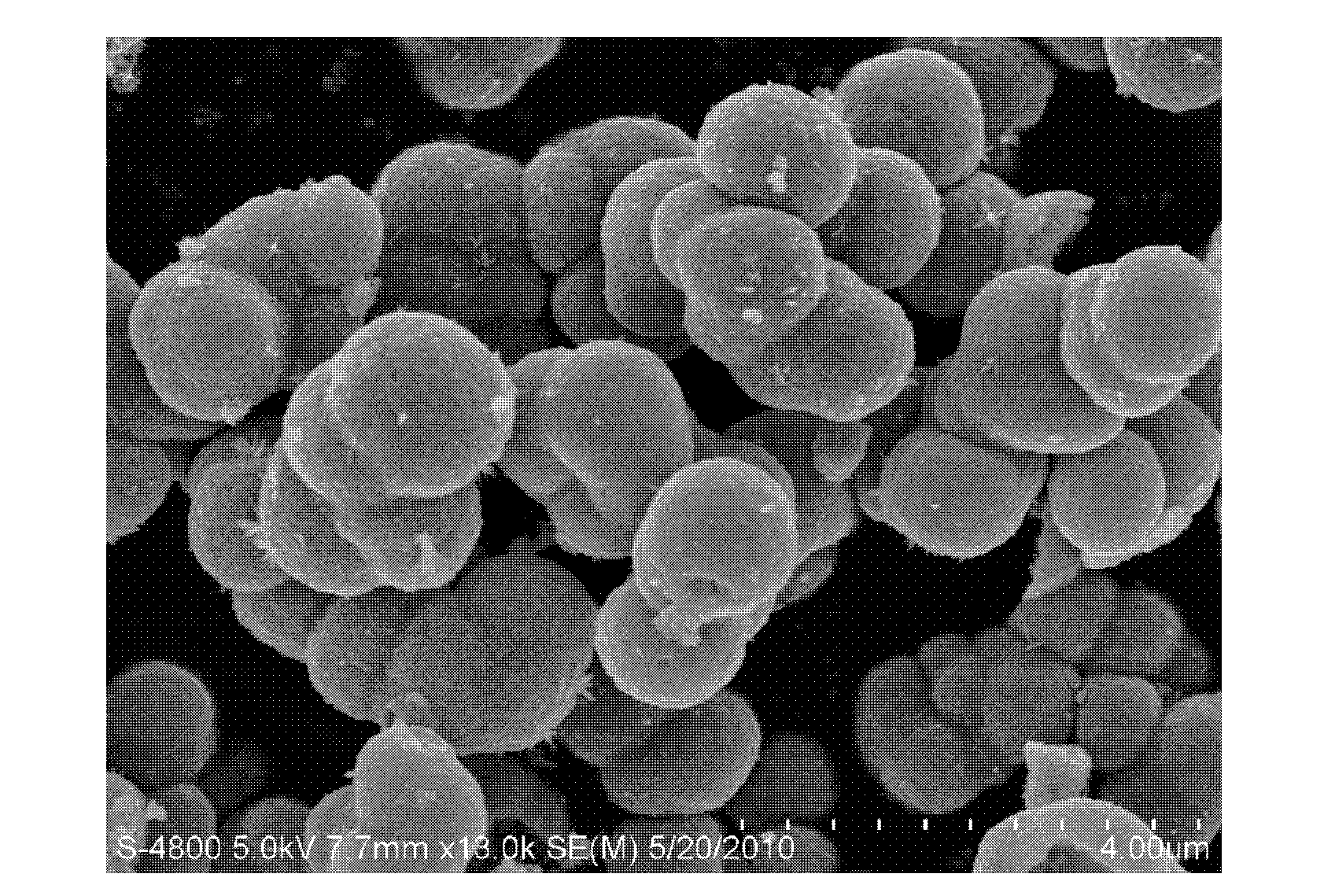

[0043] figure 1 is prepared TiO 2 It can be seen from the XRD pattern of the product that it is mixed crystals of anatase and rutile, of which anatase accounts for about 80% and rutile accounts for about 20%. The product has high crystallinity and purity. figure 2 is prepared TiO 2 The low-magnification field emission scanning electron microscope image of the product shows that the product is composed of a large number of spherical structures, the size of the balls is uniform, and the average d...

Embodiment 2

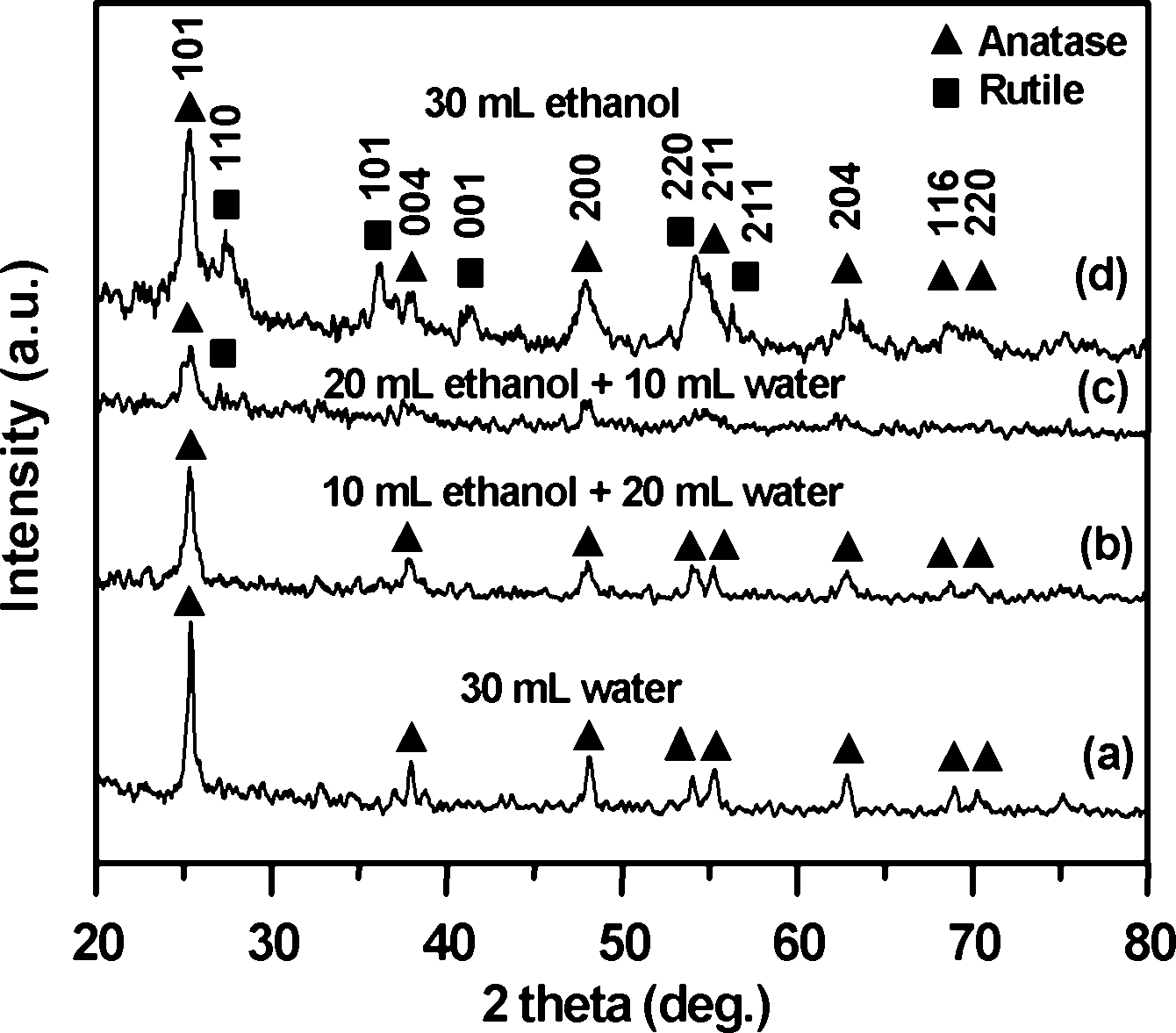

[0045] 3ml of TiCl3 hydrochloric acid solution (volume fraction 15%~20%) solution is added to alcoholic water, alcoholic water volume ratio is respectively 0: 30 (a), 10: 20 (b), 20: 10 (c) altogether 30ml, Add 1.75ml of acetic acid, 1ml of polyethylene glycol 200 (PEG200) and 0.2g of urea successively under continuous stirring, put the prepared reaction solution into a hydrothermal reaction kettle, react at 150-200°C for 8-24 hours, cool, The precipitate in the product was separated, washed with water and alcohol, filtered, and dried to obtain the product. The sample prepared according to Example 1 is named (d).

[0046] image 3 is prepared TiO 2 The XRD pattern of product, as can be seen from the figure, along with the increase of the amount of ethanol, TiO 2 The crystal form of TiO gradually changes from pure anatase to mixed crystal of anatase and rutile, so that we can control the ratio of alcohol and water to control the TiO 2 The crystal form to get the crystal for...

Embodiment 3

[0048] The amount of Example 1 is scaled up. Add 12ml of TiCl3 hydrochloric acid solution (volume fraction 15% to 20%) to 30ml of absolute ethanol, add 1.7ml of acetic acid, 4ml of polyethylene glycol 200 (PEG200) and 0.8g of urea in succession under continuous stirring, and make the prepared The reaction solution is put into a hydrothermal reaction kettle, reacted at 150-180°C for 8-12 hours, cooled, the precipitate in the product is separated, washed with water and alcohol, filtered, and dried to obtain the product.

[0049] Figure 4 is prepared TiO 2 From the XRD pattern of the product, it can be seen from the figure that when the concentration of titanium source, PEG200, and urea in the system is enlarged, the crystal form changes from mixed crystal to pure anatase and the product has high crystallinity and purity. We can control TiO according to the amount 2 crystal form, so as to obtain the crystal form we need. Figure 5 It is a low-magnification field emission sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com