Recycled mask, preparation method and recycling method

A mask and fiber technology, applied in the field of preparation and recycling of masks, can solve the problems of long time natural degradation, short protection period, difficult long-term use, etc., to achieve high particle interception efficiency, sterilization and inactivation ability, strong adhesion The effect of adhesion, antibacterial and strong bactericidal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

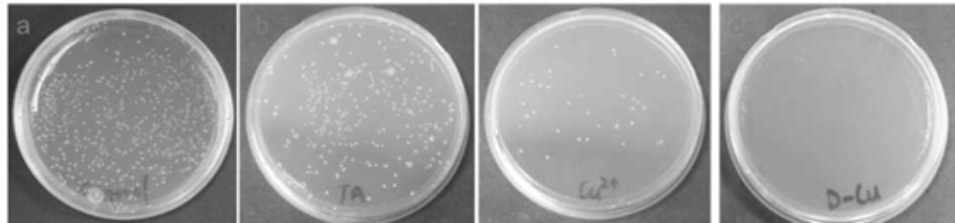

[0045] A recyclable mask comprises: a mask fiber as a base, and a highly dense nano film formed by polyphenol-metal complexing on the surface of the base.

[0046] Wherein, the raw material of described nano-film comprises plant polyphenol, metal ion and complexation enhancer solution, and the mass concentration ratio of described plant polyphenol and metal ion is 4:1~4:3; The complexation enhancer solution The pH is 6-8, and the ingredients include any one or more of anhydrous citric acid, disodium hydrogen phosphate dodecahydrate, sodium bicarbonate, sodium hydroxide, sodium carbonate, etc.; the plant polyphenols include but are not limited to Any one or more of tea polyphenols, catechins, tannic acid, gallic acid, black wattle, bayberry tannin; the metal ion includes but not limited to Gu 2+ , Yb 2+ , Zn 2+ 、Sm 3+ , La 2+ 、Gd 2+ , Fe 3+ any one or more of them.

[0047] The plant polyphenol solution, the metal ion solution and the complexing enhancer solution used in...

Embodiment 2

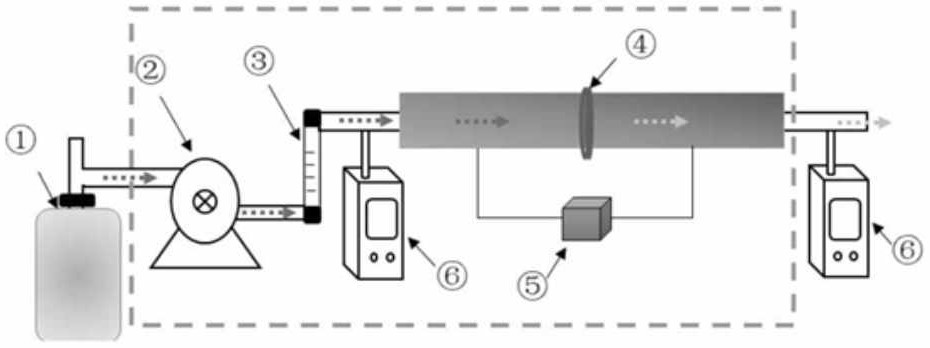

[0051] Method for preparing reusable masks:

[0052] The plant polyphenol solution and the metal ion solution are mixed according to the volume ratio of 1:1 and then sprayed on the surface of the base mask fiber to complete the first spraying; then the complexation enhancer solution is used for the second spraying to form a stable nano-film, and then use Rinse with water, remove excess impurities, and dry naturally.

[0053] Wherein, the total volume ratio of the complexation enhancer solution to the plant polyphenol solution to the metal ion solution is 1:1˜3:1.

[0054] For the first time, the plant polyphenol solution was mixed with the metal ion solution in order to make the polyphenol-metal form a low ligand and attach to the surface of the mask fiber, laying the foundation for the formation of a dense polyphenol-metal supramolecular network structure protective film. When spraying the complexation enhancer solution for the second time, it promotes the in-situ formation ...

Embodiment 3

[0056] How to recycle masks:

[0057] Spray cleaning agent on the surface of the mask after use and rinse it with water to dissociate the nano-film formed by plant polyphenols, metal ions and complexing enhancer solution, and at the same time remove the particles and killed particles adhering to the nano-film Bacteria and viruses are also removed.

[0058] Wherein, the cleaning agent includes but not limited to nitric acid, EDTA, acetic acid, the mass percent concentration of the cleaning agent is 2.0% to 5.0%, and the volume of the cleaning agent is the volume of the plant polyphenol solution and the metal ion solution. 1 to 10 times the total volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com