Quantum dot light-emitting layer and preparation method and application thereof

A quantum dot light-emitting and quantum dot technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electric solid-state devices, etc., can solve problems such as high requirements for equipment capability and precision, great influence on the luminous efficiency of quantum dots, and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

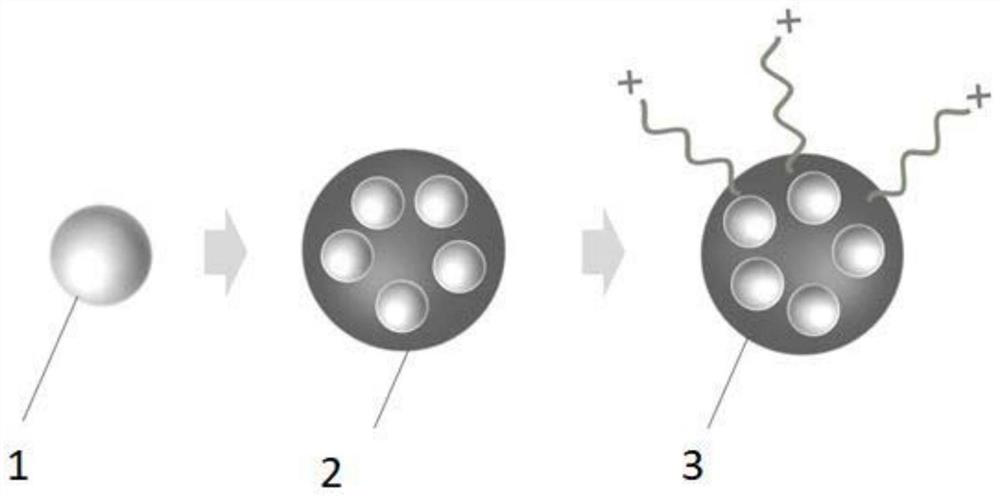

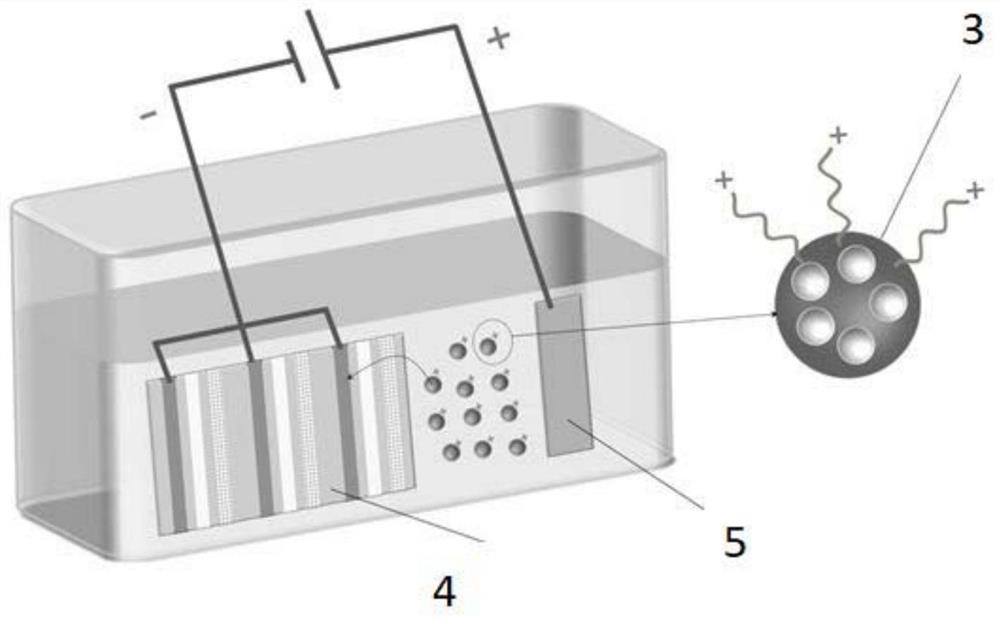

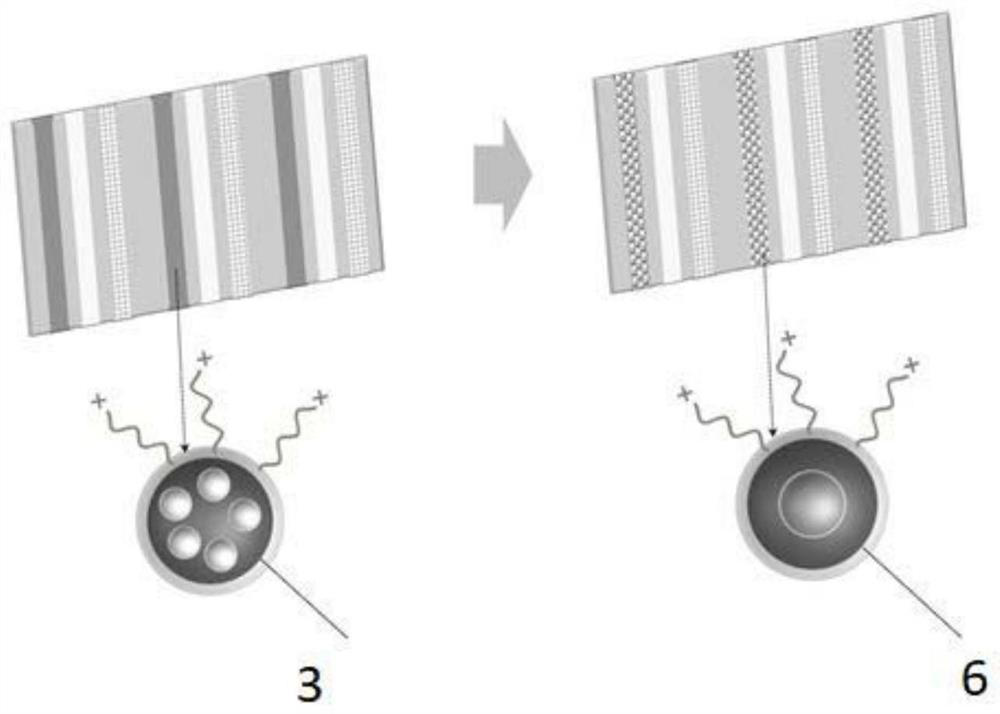

[0077] A method for preparing a quantum dot luminescent layer, specifically comprising the steps of:

[0078] (1) Preparation of the charged core quantum dot deposition solution: react the octadecene solution of the InP core with vinyltriethoxysilane for 6 minutes to obtain an intermediate product; add sodium acetate to mix at 220°C, Among them, the molar concentration of the InP core in the octadecene solution is 2.5mol / L, the concentration of vinyltriethoxysilane in the octadecene solution is 0.5mol / L, and the molar concentration of sodium acetate in the octadecene solution is 120mol / L; Reaction 45min, obtain charged InP core deposition solution (red light core quantum dot deposition solution); Under the same conditions, replace the InP core with CsPbBr 3 Core, repeat the above steps to get charged CsPbBr 3 Core deposition solution (green light core quantum dot deposition solution); replace the InP core with a CdSe core, repeat the above steps to obtain a charged InP core ...

Embodiment 2

[0083] A kind of preparation method of quantum dot luminescent layer, its difference with embodiment 1 only lies in step (1) InP core quantum dot, CsPbBr in octadecene solution 3 The molar concentration of core quantum dots and CdSe core quantum dots is 0.25mol / L, and the molar concentration of sodium acetate in the octadecene solution is 12mol / L; other component dosages and experimental conditions are all the same as in Example 1, and the quantum Point glow layer.

Embodiment 3

[0085] A kind of preparation method of quantum dot luminescent layer, its difference with embodiment 1 only lies in step (1) InP core quantum dot, CsPbBr in octadecene solution 3 The molar concentration of the core quantum dots and the CdSe core quantum dots is 5mol / L, and the molar concentration of sodium acetate in the octadecene solution is 240mol / L; other component dosages and experimental conditions are the same as in Example 1, and the quantum dots are obtained luminous layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com