Feed for beef cattle fattening

A feed and beef cattle technology, applied in the field of animal husbandry, can solve the problems of poor release and absorption of vitamins and amino acids, restrictions on the enthusiasm of beef cattle farmers, and low absorption and utilization of dry matter, so as to improve absorption and utilization and increase daily Effects of weight gain and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017]A fine material supplement that is used as a bacteric sorbate in the late stage of meat, which is specifically that the number of various raw materials needed in the 1000 kg of the fine material supplement is as follows: 300 ~ 400 kg of corn, 250 ~ 300, barley Kick, 150-20 kg of soybean meal, 50 ~ 150 kg, corn DDGS 50 ~ 80 kg, stone powder 8 ~ 15 kg, calcium hydrogen phosphate calcium, 5 ~ 10 kg of salt, 2 ~ 3,000 organic calcium 2 to 5 kilograms of yeast culture, 2 to 3 kilograms of active microecological preparation, 1 ~ 2 kg of trace element premix, 0.2 ~ 1 kg of tumor stomach vitamin, 1 to 3 khatrointestinal amino acids; wherein organometry is Mixtures of calcium alginate and magnesium alginate.

[0018]The processing method of the fine material supplement material of the present embodiment is, which will be pulverized (bulk raw materials), mixed, processed into powder-powered or particulate mixtures; the fine material is mainly used for Angers beef cattle in fattening The su...

Embodiment 2

[0022]Feed feeding during the meat, fertilized feed, the ingredients are specific, the number of various raw materials required in each 1000 kg feed is as follows: 50 ~ 100 kg of the powder, 90 ~ 100 kg of sunflower or sunflower dishes, sucrose 20 ~ 50 kg, corn 200 ~ 350 kg, skin barley 250 ~ 350 kg, soybean meal 50 ~ 150 kg, corn embryos 30 ~ 60 kg, corn DDGS 30 ~ 60 kg, 5 to 15 kg powder, calcium hydrogen phosphate 3 ~ 10 kg, salt salt 3 ~ 10 kg, organic calcium magnesium 2 ~ 5 kg, yeast culture 2 ~ 10 kg, 2 to 5 kilograms of active microecological preparation, trace element premix 1 ~ 2 kg, detecting gastrointestinal vitamin 0.5 ~ 1 kg, a petrointestinal amino acid 2 to 5 kilograms; wherein organmium magnesium is a mixture of calcium alginate and magnesium alginate.

[0023]The processing method of the feed of the present embodiment is to add the above feedstocks (bulky raw materials), and the sucrose sugar honey is added, mixed, and mixed, which is mainly used for the use of suitab...

Embodiment 3

[0027]In the feed formula of Example 1 and Example 2, organic calcium magnesium was added, and the efficacy of organic calcium magnesium was now described below.

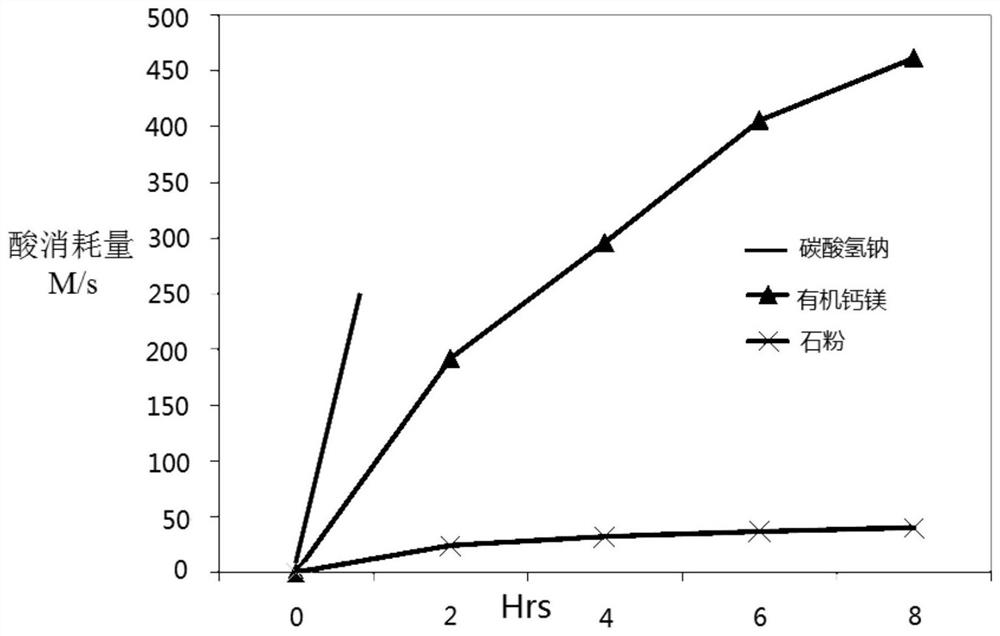

[0028]There is a large number of sodium bicarbonate (commonly known as small soda) in domestic domestically, in China, the regulation of rumen pH is used, however, sodium bicarbonate is very limited in the regulation of rumen, and the addition of sodium bicarbonate It will affect the adverse material supplement; and the effect of organic calcium magnesium and the acid is better, and the animals can be stimulated to rump, so that the animals keep the healthy state of the tumor stomach, which in turn effectively improves the dry matter feeding; therefore, this The application does not add sodium hydrogencarbonate to relieve rumen acidosis.

[0029]About the results of adding organic calcium magnesium-related tests are as follows.

[0030]figure 1 Comparison of acid neutralization time of organic calcium magnesium, stone powder and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com