Preparation method of lithium ion conductor coated lithium-rich manganese-based positive electrode material

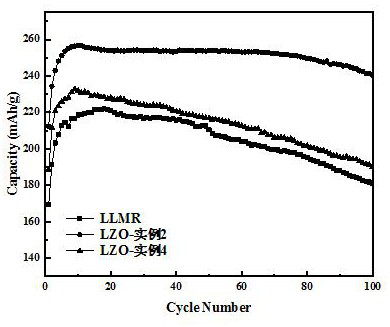

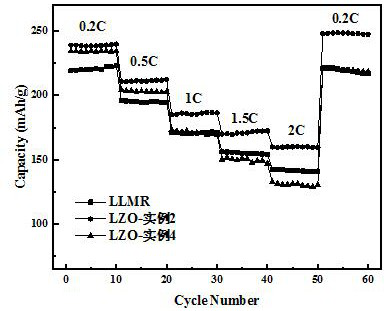

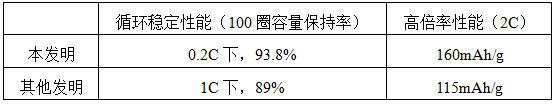

A lithium-rich manganese-based, positive electrode material technology, applied in the direction of positive electrodes, chemical instruments and methods, battery electrodes, etc., can solve the problems of poor cycle stability, high rate performance, and large irreversible capacity, and achieve cycle performance and rate performance Improvement, reduction of lithium ion consumption, and easy availability of synthetic raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Will Mn 0.667 Ni 0.166 co 0.166 CO 3 Disperse with lithium carbonate in 10mL of absolute ethanol at a molar ratio of 1:1.1, stir for 3 hours, and mix well. Then the solution was dried at 80°C for 5 hours, and the obtained powder was placed in a muffle furnace, and kept at 450°C for 10 hours at a heating rate of 3-5°C / min, and then cooled to room temperature, and then heated at 3-5°C The heating rate of / min raises the temperature to 850 ° C for 16 hours, and cools naturally to room temperature to obtain a lithium-rich manganese-based positive electrode material with the chemical formula Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 .

[0034] Weigh zirconium oxynitrate (ZrO(NO 3 ) 2 ) 1.52mg. Dissolve zirconium oxynitrate and lithium nitrate in 40mL of absolute ethanol at a molar ratio of 2:1, add 2.01mg of urea and stir at a constant speed for 2 hours. After completely dissolving, add 200mg of the prepared lithium-rich manganese-based positive electrode material, Conti...

Embodiment 2

[0036] Will Mn 0.667 Ni 0.166 co 0.166 CO 3Disperse with lithium carbonate in 10mL absolute ethanol at a molar ratio of 1:1.05, stir for 3 hours, and mix well. Then the solution was dried at 80°C for 5 hours, and the obtained powder was placed in a muffle furnace, and kept at 450°C for 6 hours at a heating rate of 3-5°C / min, and then cooled to room temperature, and then heated at 3-5°C The heating rate of / min raises the temperature to 850 ° C for 12 hours, and naturally cools to room temperature to obtain a lithium-rich manganese-based positive electrode material with the chemical formula Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 .

[0037] Weigh 3.05 mg of zirconium oxynitrate, dissolve zirconium oxynitrate and lithium nitrate in 40 mL of absolute ethanol at a molar ratio of 2:1, add 4.04 mg of urea, stir at a constant speed for 2 hours, and add the prepared lithium-rich manganese base after completely dissolving 200mg of positive electrode material, continue to stir for 1...

Embodiment 3

[0039] Will Mn 0.667 Ni 0.166 co 0.166 CO 3 Disperse in 10mL of absolute ethanol with lithium carbonate at a molar ratio of 1:1.15, stir for 3 hours, and mix well. Then the solution was dried at 80°C for 5 hours, and the obtained powder was placed in a muffle furnace, and kept at 450°C for 7 hours at a heating rate of 3-5°C / min, and then cooled to room temperature, and then heated at 3-5°C. The heating rate of / min increases the temperature to 850°C for 13 hours, then cools naturally to room temperature, and the chemical formula of the lithium-rich manganese-based positive electrode material is Li 1.2 mn 0.54 Ni 0.13 co 0.13 o 2 .

[0040] Weigh 4.60 mg of zirconium oxynitrate, dissolve zirconium oxynitrate and lithium nitrate in 40 mL of absolute ethanol at a molar ratio of 2:1, add 6.1 mg of urea, stir at a constant speed for 2 hours, and add the prepared lithium-rich manganese base after completely dissolving 200mg of positive electrode material, continue to stir f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com