A connection structure and brazing method for welding titanium and copper by using multi-intermediate brazing filler metal

A technology for connecting structures and intermediate layers, which is applied in welding/welding/cutting items, welding equipment, manufacturing tools, etc., and can solve problems such as high cost and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

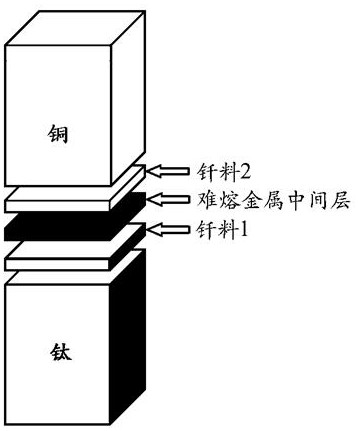

[0041] Example 1: see figure 1 , a connection structure for welding titanium and copper using multi-intermediate brazing filler metal, including titanium base material and copper base material, a multi-intermediate layer structure is arranged between the surfaces to be welded between the titanium base material and the copper base material, and the multi-intermediate layer structure Including solder 1 and solder 2, a refractory metal intermediate layer is arranged between the solder 1 and the solder 2, and the refractory metal interlayer does not melt within the brazing temperature range; the solder 1 is located between the titanium base material and the titanium base material. Between the refractory metal intermediate layers, and melting at the brazing temperature to achieve diffusion brazing connection; the brazing filler metal 2 is located between the refractory metal intermediate layer and the copper base material, and melted at the brazing temperature to achieve active braz...

specific Embodiment approach

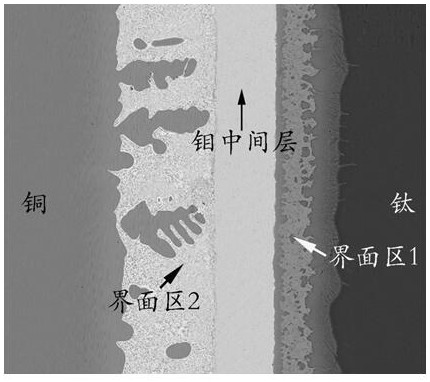

[0053] The specific implementation is as follows, the copper base material is T2 pure copper square bar, the size is 20 × 20 × 35 mm 3 ; Titanium base material is TA2 industrial pure titanium square bar, its size is 20 × 20 × 35 mm 3 .

[0054] Solder 1 is amorphous Ti-26Zr-26Ni with a melting point of 850°C and a thickness of 30 microns; solder 2 is Ag-36.5Cu-1.5Ti active solder with a melting point of 830°C and a thickness of 100 microns; refractory The metal intermediate layer is made of molybdenum, and the molybdenum intermediate layer is pure molybdenum foil with a thickness of 30 microns.

[0055] In the embodiment 1, a brazing method for welding titanium and copper using multi-intermediate brazing filler metal, comprising the following steps:

[0056] Step 1: Pretreatment of the titanium base metal and copper base metal to be welded

[0057] Wire cutting was used to cut samples with a length of 35 mm from TA2 industrial pure titanium square bars and T2 pure copper sq...

Embodiment 2

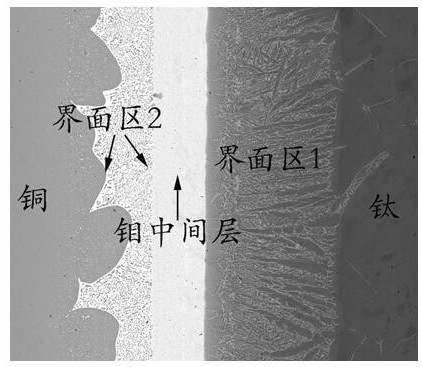

[0070] Example 2: The difference from Example 1 is that the size of the copper base material is 20×20×35 mm 3 The T2 pure copper square bar; the titanium base material adopts the size of 20 × 20 × 35 mm 3 TA2 industrial pure titanium square bar; solder 1 uses amorphous Zr-24Ti-16Ni-10Cu with a melting point of 790°C and a thickness of 30 microns; solder 2 uses Ag-28Cu with a melting point of 800°C and a thickness of 100 microns -2Ti active brazing filler metal; while the refractory metal interlayer adopts a niobium interlayer with a thickness of 30 microns, and the niobium interlayer is a pure niobium foil.

[0071] In the embodiment 2, a brazing method for welding titanium and copper using multi-intermediate brazing filler metal, comprising the following steps:

[0072] Step 1: Pretreatment of the titanium base metal and copper base metal to be welded

[0073] Wire cutting was used to cut samples with a length of 35 mm from TA2 industrial pure titanium square bars and T2 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com