Concrete micro-expansion reinforcing agent, preparation method thereof, concrete and application thereof

A concrete and micro-expansion technology, applied in the direction of buildings, bridges, bridge materials, etc., can solve the problems of increased shrinkage and deformation of concrete, lower water-cement ratio, and lower early strength, so as to promote redispersion and hydration, and improve cement moisture. The degree of crystallization and the effect of improving the crystal configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment C30-1

[0050] Example C30-1 proposes a concrete micro-expansion enhancer and concrete prepared therefrom.

[0051] The preparation method of the concrete micro-expansion reinforcing agent of embodiment C30-1 comprises the following steps: on the mass basis of the concrete micro-expansion reinforcing agent, mix 75% rapid-hardening sulfoaluminate cement, 24.6% anhydrite and 0.4% nanometer silicon hydrate Calcium acid whiskers are calcined at a temperature of 1250°C to melt for solid-state reaction, and then cooled to obtain granules and ground to obtain a concrete micro-expansion enhancer.

[0052] The concrete micro-expansion enhancer prepared in Example C30-1 was mixed with other concrete raw materials to obtain concrete, and its raw material components are shown in Table 3.

[0053] Among them, the main components of cement are: C 3 S (tricalcium silicate), C 2 S (dicalcium silicate), C 3 A (tricalcium aluminate), C 4 AF (tetracalcium aluminoferrite).

Embodiment C30-2

[0055] Example C30-2 proposes a concrete micro-expansion enhancer and concrete prepared therefrom.

[0056] The preparation method of the concrete micro-expansion reinforcing agent of embodiment C30-2 comprises the following steps: on the mass basis of the concrete micro-expansion reinforcing agent, mix 85% rapid-hardening sulfoaluminate cement, 14.5% anhydrite and 0.5% nanometer silicon hydrate Calcium acid whiskers are calcined at a temperature of 1300°C to melt for solid-state reaction, and then cooled to obtain granules and ground to obtain a concrete micro-expansion enhancer.

[0057] The concrete micro-expansion enhancer prepared in Example C30-2 was mixed with other concrete raw materials to obtain concrete, and its raw material components are shown in Table 3.

[0058] Among them, the main components of cement are: C 3 S (tricalcium silicate), C 2 S (dicalcium silicate), C 3 A (tricalcium aluminate), C 4 AF (tetracalcium aluminoferrite).

Embodiment C30-3

[0060] Example C30-3 proposes a concrete micro-expansion enhancer and concrete prepared therefrom.

[0061] The preparation method of the concrete micro-expansion reinforcing agent of embodiment C30-3 comprises the following steps: on the mass basis of the concrete micro-expansion reinforcing agent, mix 65% rapid-hardening sulfoaluminate cement, 14.5% anhydrite and 0.5% nanometer silicon hydrate Calcium acid whiskers are calcined at a temperature of 1300°C to melt for solid-state reaction, and then cooled to obtain granules and ground to obtain a concrete micro-expansion enhancer.

[0062] The concrete micro-expansion enhancer prepared in Example C30-3 was mixed with other concrete raw materials to obtain concrete, and its raw material components are shown in Table 3.

[0063] Among them, the main components of cement are: C 3 S (tricalcium silicate), C 2 S (dicalcium silicate), C 3 A (tricalcium aluminate), C 4 AF (tetracalcium aluminoferrite).

[0064] The concrete micr...

PUM

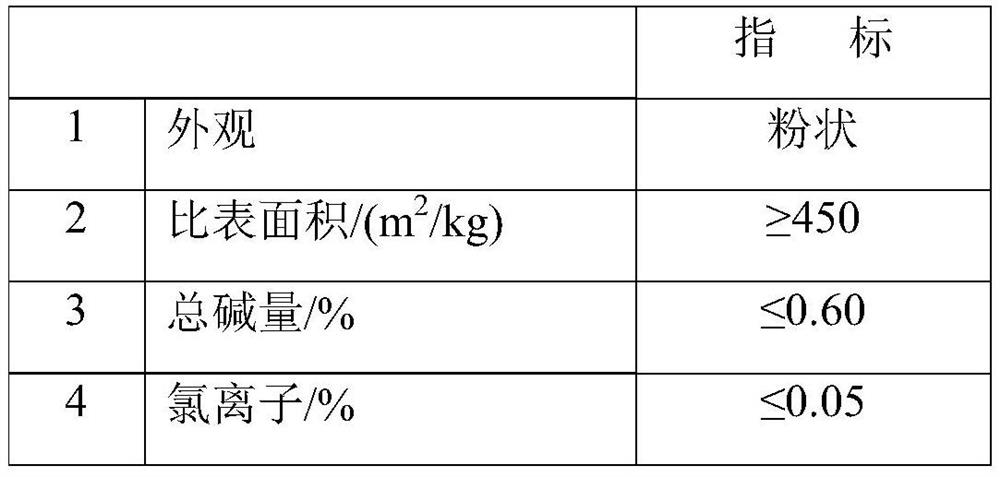

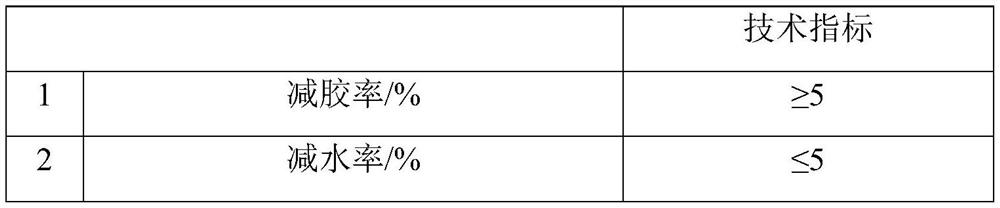

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com