Berberine hydrochloride pellet and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of berberine hydrochloride pellets, after berberine hydrochloride is prepared into quick-release pellets according to prescription, after adopting gelatin hollow capsules to fill, obtain promptly; Said prescription composition is as follows:

[0036] 54.47% of berberine hydrochloride, 10.89% of corn starch or microcrystalline cellulose, 8.50% of pregelatinized starch, 3.81% of carboxymethyl starch sodium or carmellose calcium, and the balance is water or aqueous solution. Water is purified water.

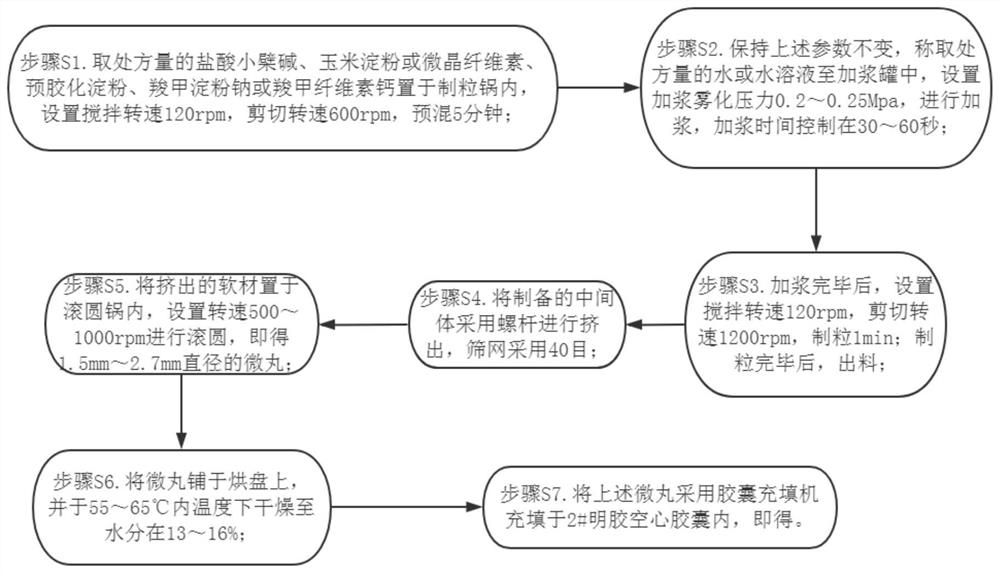

[0037] A preparation method for berberine hydrochloride pellets, for preparing berberine hydrochloride pellets, such as figure 1 shown, including the following steps:

[0038] Step S1. Get the berberine hydrochloride, cornstarch or microcrystalline cellulose, pregelatinized starch, carboxymethyl starch sodium or carmellose calcium of prescription quantity and place in the granulating pot, set stirring speed 120rpm, shearing speed 600rpm, premix for 5 minutes;

[003...

Embodiment 2

[0055] Embodiment 2 is a further application of Embodiment 1.

[0056] 1) Take 100g of berberine hydrochloride, 20g of cornstarch, 15.6g of pregelatinized starch, and 7g of carboxymethyl starch sodium and place them in the granulation pot, set the stirring speed at 120rpm, the shearing speed at 600rpm, and pre-mix for 5 minutes; 2) keep The above parameters remain unchanged, weigh 41g of purified water into the slurry tank, set the atomization pressure of slurry addition to 0.2-0.25Mpa, and perform slurry addition, and the slurry addition time is controlled at 30-60 seconds; 3) After the slurry addition is completed, set the stirring The rotation speed is 120rpm, the shear rotation speed is 1200rpm, and the granulation is 1min. After the granulation is completed, the material is discharged; 4) The prepared intermediate is extruded by a screw, and the screen is 40 mesh; 5) The extruded soft material is placed in a spheronizing pot, and the speed is set at 500-1000rpm for sphero...

Embodiment 3

[0058] Embodiment 3 is a further application of Embodiment 1.

[0059] 1) Take 100g of berberine hydrochloride, 20g of microcrystalline cellulose, 15.6g of pregelatinized starch, and 7g of carboxymethyl starch sodium in a granulation pot, set the stirring speed at 120rpm, the shearing speed at 600rpm, and pre-mix for 5 minutes; 2 ) Keep the above parameters unchanged, weigh 41g of purified water into the slurry tank, set the atomization pressure of slurry addition to 0.2-0.25Mpa, and add slurry, and the slurry addition time is controlled at 30-60 seconds; 3) After the slurry addition is completed, Set the stirring speed at 120rpm, the shearing speed at 1200rpm, and granulate for 1min. After the granulation is completed, the material is discharged; 4) The prepared intermediate is extruded by a screw, and the screen is 40 mesh; 5) The extruded soft material is placed in a spheronizing pot, and the speed is set at 500-1000rpm for spheronization, that is Obtain pellets with a dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com